Iron ore sintering system and method

A technology of iron ore and sintered ore, which is applied in the fields of steelmaking and environmental protection, can solve the problems of secondary pollution, large investment, and difficulty in industrialization and application, and achieve the improvement of waste heat recovery efficiency, energy utilization efficiency, and elimination of white smoke vision pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

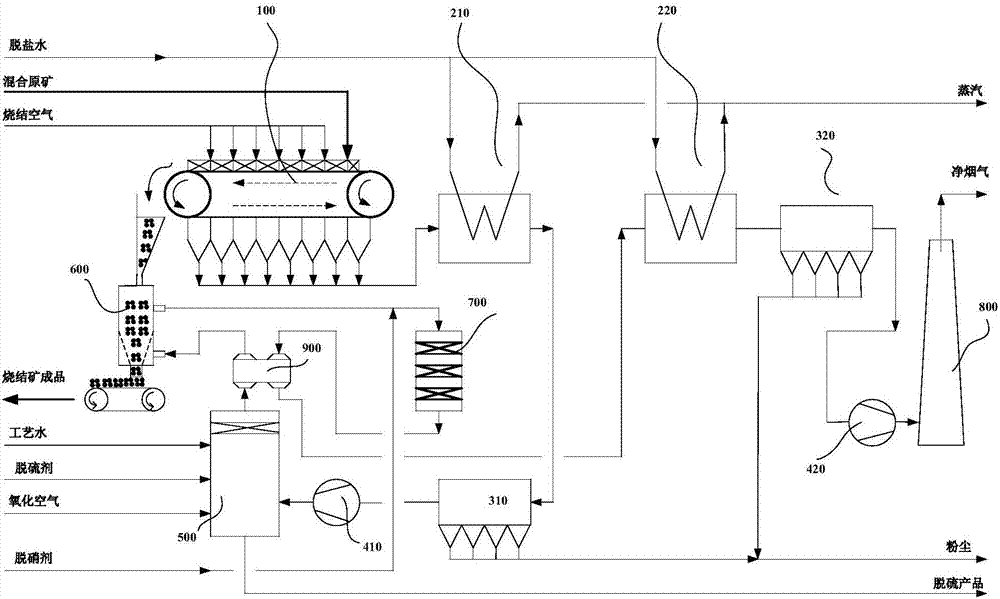

[0028] A steel factory has a 360m 2 The sintering machine emits 1.2 million Nm of flue gas per hour during normal production 3 , applied as figure 1 The shown iron ore sintering system includes a sintering machine 100, a sinter cooler 600 and a smoke stack 800, and also includes two waste heat boilers, two dust collectors, a flue gas desulfurization tower, a flue gas denitrification reactor and two Induced fans, respectively as shown in the figure: the first waste heat boiler 210, the second waste heat boiler 220, the first dust collector 310 and the second dust collector 320, a flue gas desulfurization tower 500, a flue gas denitrification reactor 700, the second An induced draft fan 410 and a second induced draft fan 420. The downstream of the sintering machine 100 is sequentially connected to the first waste heat boiler 210, the first dust collector 310, the first induced draft fan 410, and the flue gas desulfurization tower through the flue gas pipeline. 500, sinter cool...

Embodiment 2

[0041] A steel plant application such as figure 1 The iron ore sintering system shown is different from Embodiment 1 in that in order to improve the desulfurization efficiency of sintering flue gas, the flue gas desulfurization tower 500 is a wet scrubber structure. Using the same iron ore sintering method as in Example 1, the sulfur dioxide content of the inlet flue gas of the exhaust chimney 800 is further reduced to 30mg / Nm 3 the following.

Embodiment 3

[0043] A steel plant application such as figure 1 A kind of iron ore sintering system shown is different from embodiment 1 in that the iron ore sintering method adopted comprises the following steps:

[0044] (1) Iron ore sintering: the raw ore with the mixed formula is added to the crawler from the head of the sintering machine 100, and then a layer of material with a certain thickness is formed through cloth, and sintering starts after ignition, and the sintering air is sucked into the material layer, the track moves at a certain speed, so that the sintered material layer moves from the head to the tail, and completes the entire sintering process; at the same time, the flue gas formed by sintering contains sulfur dioxide, NO x , dust and other pollutants, which are divided into two streams of flue gas, flue gas at the nose and tail flue gas. The content of sulfur dioxide is 1500–2600mg / Nm 3 ,NO x The content is 400–550mg / Nm 3 between;

[0045] (2) Heat recovery from sin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com