Porous carbon solid-phase micro-extraction coating and its preparation and application

A porous carbon and coating technology, which is applied in the field of analytical chemistry and environmental monitoring, can solve the problems of difficult monitoring of volatile organic compounds and immature monitoring methods of volatile organic pollutants, and achieve excellent thermal stability, strong extraction performance, and production The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

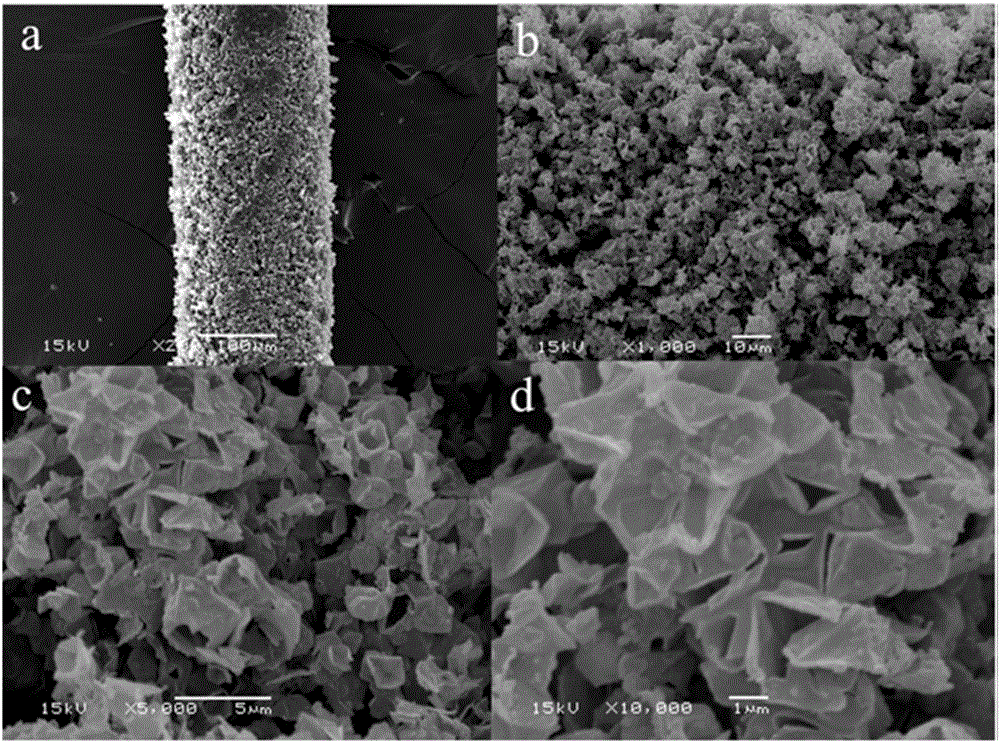

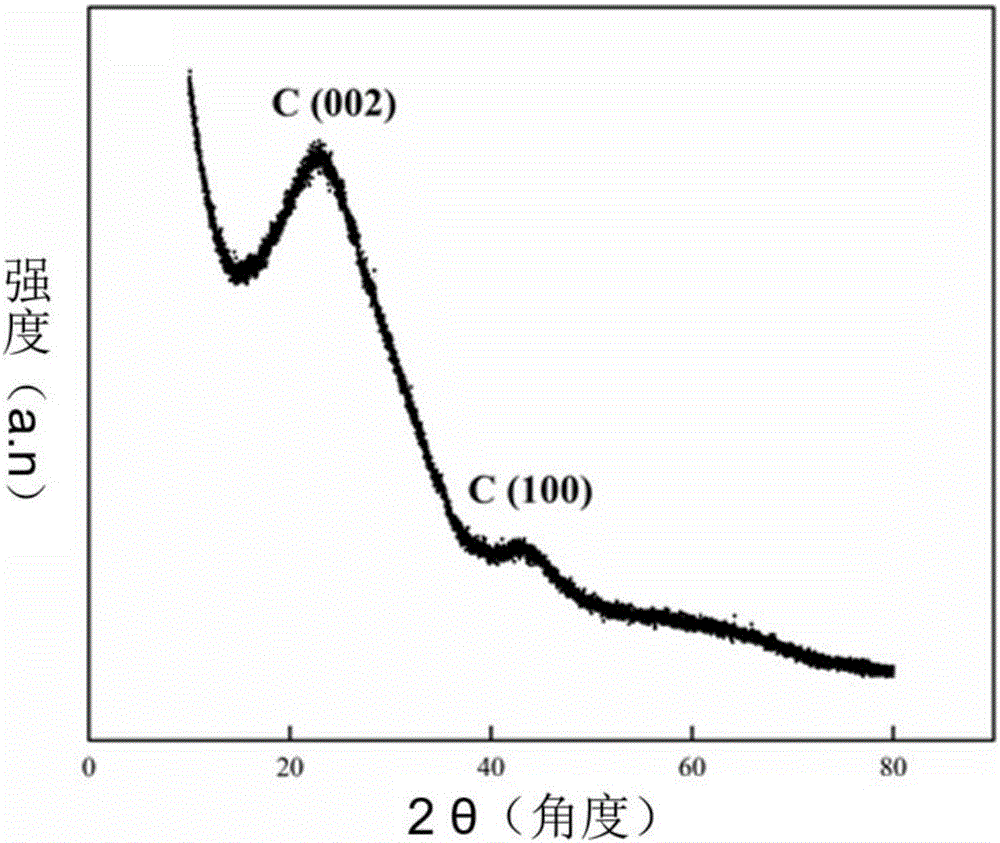

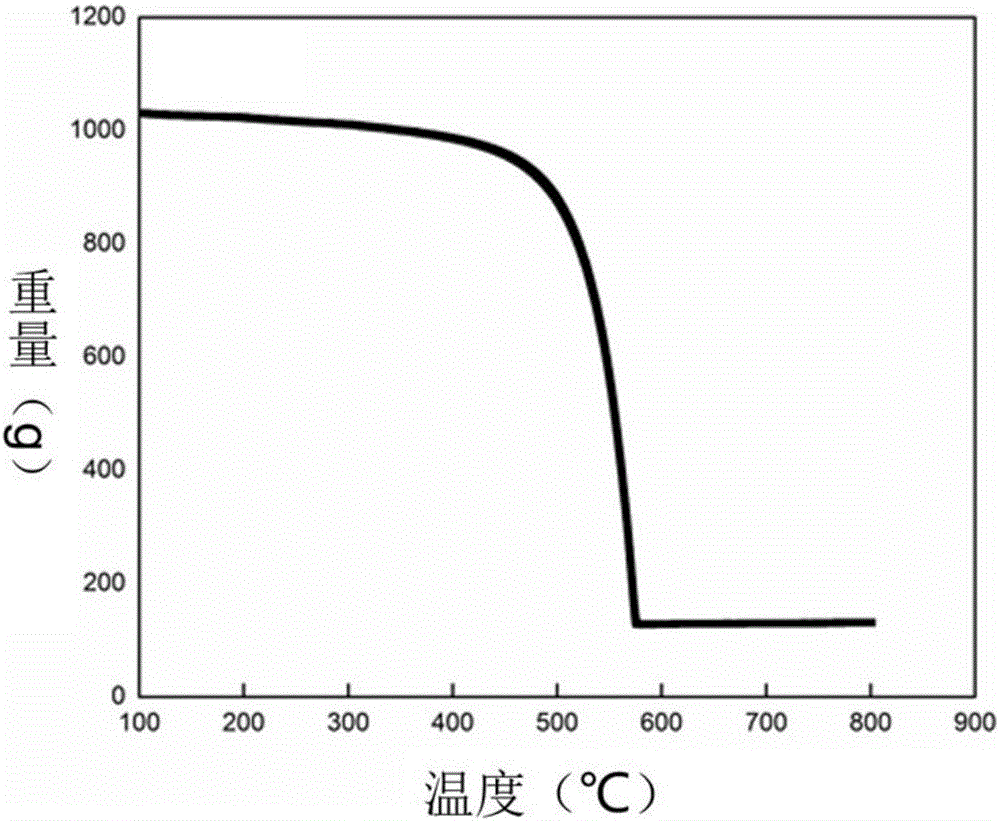

[0024] In this example, by selecting six chlorobenzene compounds as the representative substances of volatile organic pollutants, the method for the determination of volatile organic pollutants in water bodies by the new porous carbon solid-phase microextraction coating is illustrated. The analysis results of the prepared coating can be found in the attached Figure 1~5 .

[0025] Preparation of porous carbon material: Put potassium citrate in an oven at 120°C for overnight drying, weigh 5.0000g of potassium citrate with a high-precision balance, place it in a boat-shaped crucible, and then place it in a TL1200 tube furnace at 3°C / min Raise the temperature to 850°C, keep it for 1h, pass nitrogen gas (50mL / min) for protection during the whole process, and finally cool down naturally to complete the carbonization process. After the material is cooled to room temperature, use a large amount of 10% (V / V) hydrochloric acid to wash and filter to remove impurities, then use excess de...

Embodiment 2

[0031] In this example, the extraction performance of the new porous carbon SPME coating is illustrated by comparing the extraction amount of six chlorobenzene compounds with commercial coating polydimethylsiloxane. Preparation of porous carbon material, porous carbon material coating and extraction process are consistent with Example 1. First use polydimethylsiloxane to extract six kinds of chlorobenzenes, and then use porous carbon coating to extract six kinds of chlorobenzenes with the same concentration, repeat three times for analysis, the results are shown in Figure 5 . For the six chlorobenzene compounds, the extraction amount of the porous carbon coating was higher than that of the commercial polydimethylsiloxane coating, and the extraction amount was 2.14-42.37 times that of polydimethylsiloxane. It shows that the porous carbon coating of the present invention can efficiently and accurately determine trace amounts of volatile organic pollutants in water environment,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com