A kind of processing method of sorbic acid waste water

A technology of sorbic acid wastewater and treatment method, applied in anaerobic digestion treatment, water/sewage treatment, aerobic process treatment and other directions, can solve the problems of high operating cost, high cost, low biochemical treatment efficiency, etc., and reduce the difficulty of treatment. , The effect of improving the removal capacity and saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

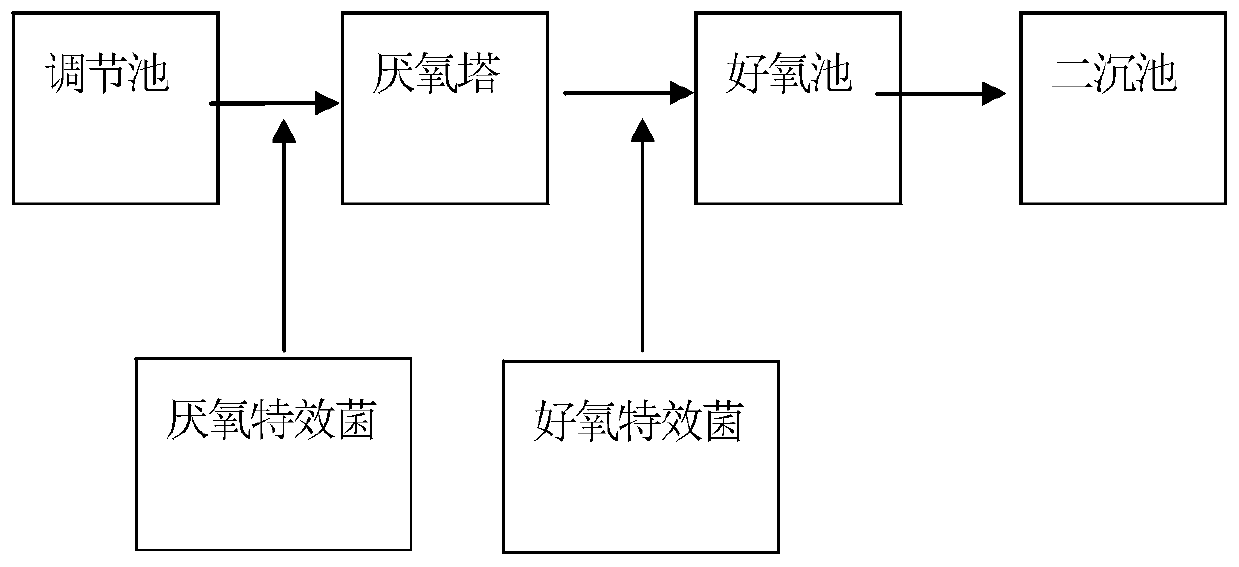

[0035] A treatment method for sorbic acid wastewater, comprising a biochemical system for wastewater treatment, an anaerobic process and an aerobic process, the treatment method comprising:

[0036] The sorbic acid raw water is mixed with the effluent of the secondary sedimentation tank of the biochemical system as the wastewater for activating the bacterial agent: the specially selected strains for domestication are as follows:

[0037] 1. The proportion and cultivation method of the bacteria added in the anaerobic process:

[0038] The proportion of strains added in the anaerobic process is: 15% of Clostridium, 20% of Bacteriodes, 20% of Butyrivibrio, 10% of Methanobacter brucei, 10% of thermophilic Methanobacterium 20%, Methanospirillum henzii 5%, Methanococcus 10%

[0039]According to the above ratio, the ratio of sorbic acid raw water: system secondary sedimentation tank effluent: composite bacteria is 5:100:1, and the temperature is controlled at 38 degrees in a stirrin...

Embodiment 2

[0055] 1. The proportion and cultivation method of the bacteria added in the anaerobic process:

[0056] The proportion of strains added in the anaerobic process is: Acetobutylicum 18%, Bacteroides aceticum 22%, Butyrivibrio 25%, Methanobacter brucei 8%, Methanobacterium thermoautotrophicum 15% , Methanospirillum henzii 5%, Methanococcus 7%.

[0057] According to the above ratio, the ratio of sorbic acid raw water: system secondary sedimentation tank effluent: composite bacteria is 5:100:1.5, and the temperature is controlled at 39 degrees in a stirring environment, and the activation is completed by continuous stirring for 24 hours.

[0058] 2. Proportion and activation of bacteria in aerobic process

[0059] The proportion of strains added to the aerobic process is:

[0060] Pseudomonas 15%, Rhodospirillum 12%, Pseudomonas (pro-teus vulgaris) 18%, Clostridium putrificum 13%, nitrate bacteria 2% and nitrate bacteria 13%, Bacillus subtilis 15% and Corynebacterium 12%.

[0...

Embodiment 3

[0065] 1. The proportion and cultivation method of the bacteria added in the anaerobic process:

[0066] The proportion of strains added in the anaerobic process is: Clostridium perfringens 16%, Bacteroides ovale 21%, Butyrivibrio 23%, Methanobacter brucei 12%, thermoautotrophic methane Bacillus 16%, Methanospirillum henzii 5%, Methanococcus 7%.

[0067] According to the above ratio, the ratio of sorbic acid raw water: system secondary sedimentation tank effluent: composite bacteria is 5:100:1.3, and the temperature is controlled at 40 degrees in a stirring environment, and the activation is completed by continuous stirring for 24 hours.

[0068] 2. Proportion and activation of bacteria in aerobic process

[0069] The proportion of strains added to the aerobic process is:

[0070] Pseudomonas 12%, Rhodospirillum 15%, Pseudomonas (pro-teus vulgaris) 18%, Clostridium putrificum 16%, nitrate bacteria 2% and nitrate bacteria 10%, Bacillus subtilis 15% and Corynebacterium 12%. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com