Method for preparing biological culture material by grinding and stirring before insulated fermentation

A technology of biological culture and thermal insulation fermentation, which is applied in the preparation of organic fertilizers, fertilizers made from biological wastes, and the treatment of biological organic parts, etc. It can solve the problems of low nutrient absorption efficiency and inability to meet demand.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

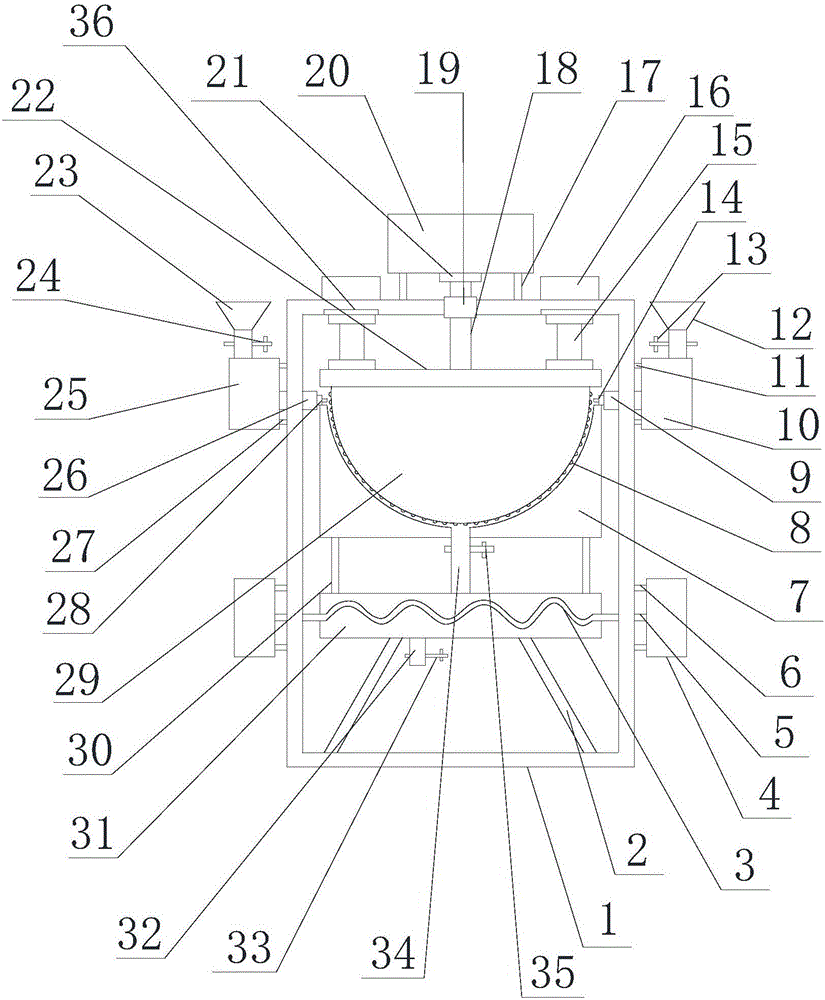

[0026] refer to figure 1 , a kind of biological compost preparation method that first grinds and stirs and then heat preservation and fermentation proposed by the present invention comprises the following steps:

[0027] S1. Configure biological culture materials: The raw materials of material A include by weight: 35 parts of cottonseed hulls, 10 parts of bagasse, 6 parts of wine tanks, 4 parts of rice bran, 2.5 parts of pine wood chips, 4.5 parts of soybean powder, 3.5 parts of palm shells, 3 parts of decomposed pig manure, 4.5 parts of sucrose, 2.5 parts of light calcium carbonate, 3.5 parts of superphosphate, 4.5 parts of potassium dihydrogen phosphate, 2.5 parts of magnesium sulfate, 6.5 parts of vitamin B;

[0028] The raw materials of material B include by weight: 5.5 parts of Prunella vulgaris residue, 6 parts of coconut shell powder, 3 parts of walnut shell powder, 2.5 parts of chestnut bract powder, 4 parts of lotus shell powder, 2.5 parts of banana stems and leaves, ...

Embodiment 2

[0031] refer to figure 1 , a kind of biological compost preparation method that first grinds and stirs and then heat preservation and fermentation proposed by the present invention comprises the following steps:

[0032] S1. Configure biological culture materials: The raw materials of material A include by weight: 25 parts of cottonseed hulls, 15 parts of bagasse, 3 parts of wine tanks, 6 parts of rice bran, 1 part of pine wood chips, 6 parts of soybean powder, 2 parts of palm shells, 5 parts of decomposed pig manure, 3 parts of sucrose, 4 parts of light calcium carbonate, 2 parts of superphosphate, 6 parts of potassium dihydrogen phosphate, 1 part of magnesium sulfate, 8 parts of vitamin B;

[0033] The raw materials of material B include by weight: 5 parts of Prunella vulgaris residue, 9 parts of coconut shell powder, 2 parts of walnut shell powder, 4 parts of chestnut shell powder, 3 parts of lotus shell powder, 4 parts of banana stem and leaf, honeysuckle stem and leaf 2 ...

Embodiment 3

[0036] refer to figure 1 , a kind of biological compost preparation method that first grinds and stirs and then heat preservation and fermentation proposed by the present invention comprises the following steps:

[0037] S1. Configure biological culture materials: The raw materials of material A include by weight: 45 parts of cottonseed hulls, 5 parts of bagasse, 9 parts of wine tanks, 2 parts of rice bran, 4 parts of pine wood chips, 3 parts of soybean powder, 5 parts of palm shells, 1 part of decomposed pig manure, 6 parts of sucrose, 1 part of light calcium carbonate, 5 parts of superphosphate, 3 parts of potassium dihydrogen phosphate, 4 parts of magnesium sulfate, 5 parts of vitamin B;

[0038] The raw materials of material B include by weight: 6 parts of Prunella vulgaris residue, 3 parts of coconut shell powder, 4 parts of walnut shell powder, 1 part of chestnut bract powder, 5 parts of lotus shell powder, 1 part of banana stem and leaf, and honeysuckle stem and leaf 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com