Metal-film porous ceramic heating element and application thereof

A technology of porous ceramics and metal membranes, which is used in applications, electric heating devices, smokers' products, etc., to achieve the effect of improving bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

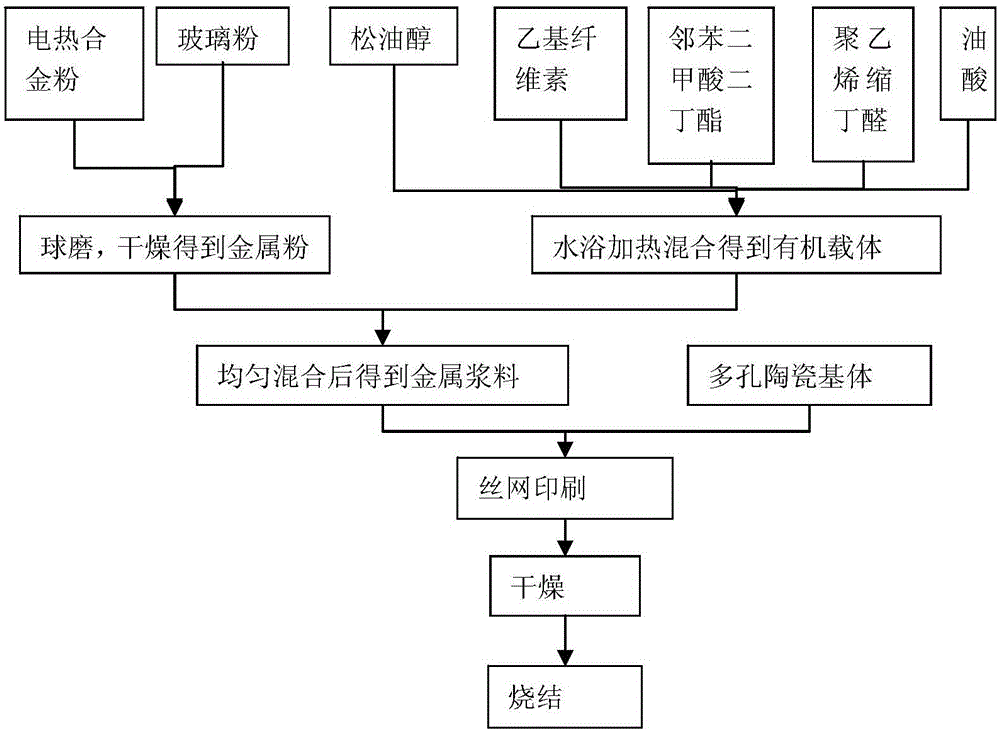

Method used

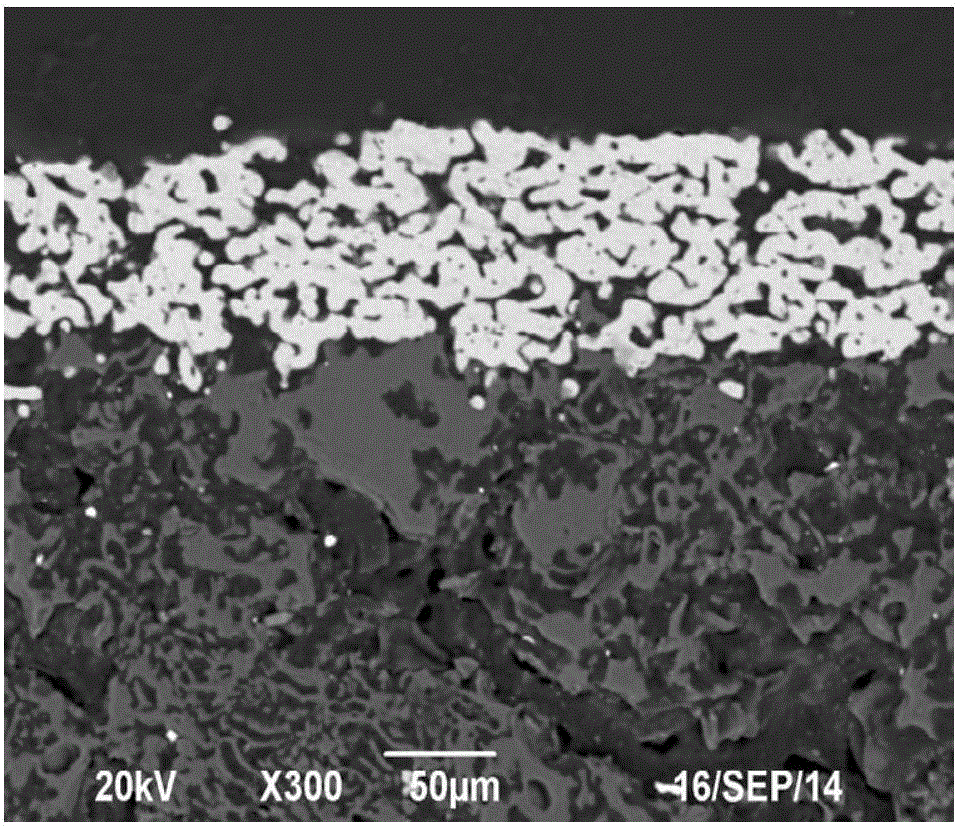

Image

Examples

Embodiment 1

[0049]Weigh nickel-copper alloy powder and glass powder with a melting point of 800°C at 80% and 20% by mass respectively; mix them and pour them into a zirconia tank, use absolute ethanol as a ball milling medium, and grind at 250r / min Ball mill for 8 hours at a rotating speed, and then put it into a blast drying oven and dry at 80° C. for 3 hours; finally pass the dried mixture of nickel-copper alloy powder and glass powder through an 80-mesh sieve.

[0050] Weigh terpineol, ethyl cellulose, dibutyl phthalate and polyvinyl butyral according to mass percent respectively as 92%, 4%, 2%, and 2%; Stir in a water bath at 80°C for 3 hours until the ethyl cellulose and polyvinyl butyral are completely dissolved; after cooling to room temperature, add 2% oleic acid in the mass of the organic mixture, heat and mix, and finally cool to room temperature.

[0051] The nickel-copper alloy powder mixture and the organic carrier are weighed and mixed according to the mass fraction of 80% a...

Embodiment 2

[0055] The nickel-chromium alloy powder and the glass powder with a melting point of 950°C are weighed at 82% and 18% by mass respectively; they are mixed and poured into a zirconia tank, and absolute ethanol is used as a ball milling medium at 250r / min Ball mill for 8 hours at a rotating speed, and then put it into a blast drying oven and dry at 80° C. for 3 hours; finally pass the dried mixture of nickel-chromium alloy powder and glass powder through an 80-mesh sieve.

[0056] Weigh terpineol, ethyl cellulose, dibutyl phthalate and polyvinyl butyral according to mass percent respectively as 91%, 5%, 2%, and 2%; Stir in a water bath at 80°C for 3 hours until the ethyl cellulose and polyvinyl butyral are completely dissolved; after cooling to room temperature, add 2% oleic acid in the mass of the organic mixture, heat and mix, and finally cool to room temperature.

[0057] The nickel-copper alloy powder mixture and the organic carrier are weighed and mixed according to the mas...

Embodiment 3

[0061] Weigh iron-chromium-aluminum alloy powder and glass powder with a melting point of 1000°C at 85% and 15% by mass respectively; mix them and pour them into a zirconia tank, use absolute ethanol as a ball milling medium, and grind at 250r / min The ball milled at a high speed for 8 hours, and then put it into a blast drying oven and dried at 80°C for 3 hours; finally, the dried mixture of iron-chromium-aluminum alloy powder and glass powder was passed through an 80-mesh sieve.

[0062] Weigh terpineol, ethyl cellulose, dibutyl phthalate and polyvinyl butyral according to mass percentage respectively as 93%, 4%, 1.5%, 1.5%; Stir in a water bath at 80°C for 3 hours until the ethyl cellulose and polyvinyl butyral are completely dissolved; after cooling to room temperature, add 2% oleic acid in the mass of the organic mixture, heat and mix, and finally cool to room temperature.

[0063] The iron-chromium-aluminum alloy powder mixture and the organic carrier are weighed and mixe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com