Synthetic adsorbent and preparation method and application thereof to degradation of VOCs

A technology of adsorbents and mixtures, applied in separation methods, chemical instruments and methods, silicon compounds, etc., can solve the problems of low efficiency of VOCs degradation, and achieve the effect of promoting the degradation of VOCs, high degradation efficiency, and good treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The preparation method of the catalyst includes the following steps:

[0036] (1) Soak the zeolite with a particle size of 0.03-0.2cm in deionized water for 0.7-1h, take it out and put it in a 6%-10% sulfuric acid solution, boil it for 0.4-0.8h, and then wash it with deionized water , Until the pH is 6.8-7.2, place in an oven at 85-88℃ to dry for 1.5-1.8h, and cool for later use;

[0037] (2) Add 18-30 mL of tin tetrabromide solution dropwise to 3-3.5 times absolute ethanol at a rate of 1 drop / s, and stir at a speed of 300-500r / min during the dropping process to prepare liquid A ; Take 2-4 mL of a palladium salt solution with a mass concentration of 0.2%-0.6% and add it dropwise to 5-12 mL of absolute ethanol at a rate of 1-2 drops / s to prepare solution B, and adjust the pH of the solution to 1.2-2.4 ; At a speed of 350-450r / min and a temperature of 42-46℃, slowly add liquid B to liquid A at a rate of 1 drop / 2-4 seconds, and control the temperature to 42-46℃. Continue to s...

Embodiment 1

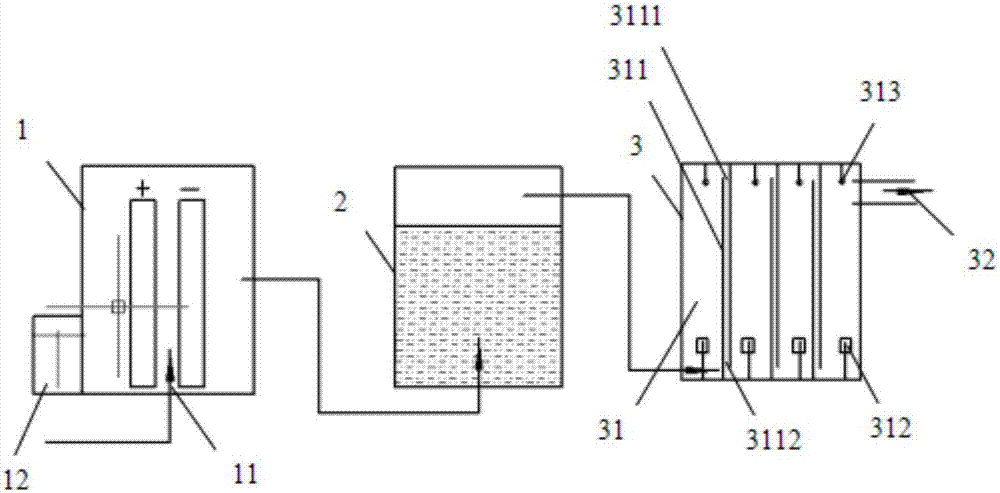

[0049] Such as figure 1 Shown: a system for degrading VOCs, including an oscillating high-pressure device 1, a filter tank 2, a bacteria-fungi compound reaction tank 3, the oscillating high-pressure device 1 and the filter tank 2 are connected by a pipe A, the The filter tank 2 is connected to the bacteria-fungus composite reaction tank 3 through a pipe B. The oscillating high-pressure device 1 includes an oscillating high-pressure device inlet 11 and a nickel-hydrogen battery 12, and the filter material in the filter pool 2 contains Activated carbon, synthetic adsorbent, catalyst, the mass ratio of the activated carbon, synthetic adsorbent, and catalyst is 26:3:1, the bacteria-fungi composite reaction tank 3 includes a mobile phase chamber 31 and an air outlet 32, the flow The number of phase chambers 31 is 4. The adjacent mobile phase chambers are separated by partitions 311 and form an inlet 3111 and an outlet 3112. Each mobile phase chamber is provided with a temperature pr...

Embodiment 2

[0070] Such as figure 1 Shown: a system for degrading VOCs, including an oscillating high-pressure device 1, a filter tank 2, a bacteria-fungus composite reaction tank 3, the oscillating high-pressure device 1 and the filter tank 2 are connected by a pipe A, the The filter tank 2 is connected with the bacteria-fungus composite reaction tank 3 through a pipe B. The oscillating high-pressure device 1 includes an oscillating high-pressure device inlet 11 and a nickel-hydrogen battery 12, and the filter material in the filter pool 2 contains Activated carbon, synthetic adsorbent, and catalyst. The mass ratio of the activated carbon, synthetic adsorbent and catalyst is 18:2:1. The bacteria-fungi composite reaction tank 3 includes a mobile phase chamber 31 and an air outlet 32. The number of phase chambers 31 is 4. The adjacent mobile phase chambers are separated by a partition 311 and form an inlet 3111 and an outlet 3112. Each mobile phase chamber is provided with a temperature pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com