Graphene-ZDTP (zinc dialkyl dithiophosphate) compound pre-dispersed rubber master batches and preparation method thereof

A technology for pre-dispersing masterbatch and graphene, applied in the field of pre-dispersing and granulating rubber additives, can solve problems such as hidden health hazards of operators, inconvenient transportation and use, pollution of workshop environment, etc., to improve mechanical properties and ensure quality. , the effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

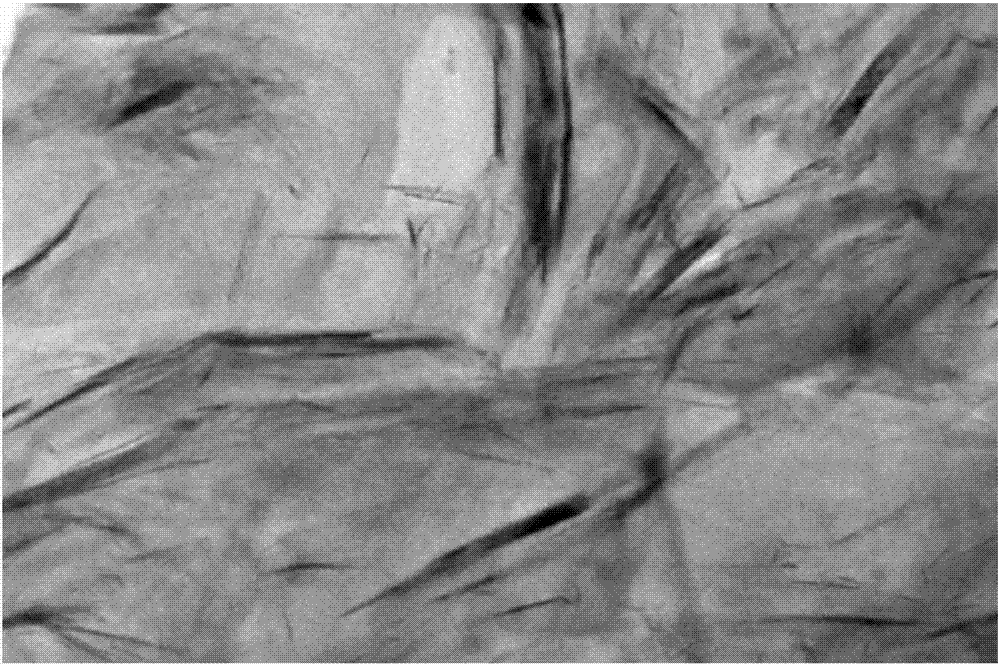

Image

Examples

Embodiment 1

[0027] The Graphene-ZDTP composite pre-dispersed masterbatch of embodiment one, its percentage by weight consists of: graphene 50%, zinc dialkyl dithiophosphate 27%, γ-aminopropyltriethoxysilane 3%, 1% of stearic acid, 1% of fatty acid soap, 2% of nano-silica with a particle size of 60-80nm, 1% of nano-alumina with a particle size of 60-80nm, 8% of styrene-butadiene rubber, and 7% of naphthenic oil.

Embodiment 2

[0028] The Graphene-ZDTP composite pre-dispersed master batch of embodiment two, its percentage by weight consists of: graphene 45%, zinc dialkyldithiophosphate 25%, gamma-aminopropyltriethoxysilane 5%, Stearic acid 2%, fatty acid soap 3%, inorganic filler 6%, EPDM rubber 8%, naphthenic oil 6%.

Embodiment 3

[0029] The Graphene-ZDTP composite pre-dispersed master batch of embodiment three, its percentage by weight consists of: graphene 46%, zinc dialkyldithiophosphate 25%, γ-aminopropyltriethoxysilane 2%, 3% of stearic acid, 2% of fatty acid soap, 3% of nano-silica with a particle size of 80-90nm, 1% of nano-alumina with a particle size of 80-90nm, 6% of acrylic rubber, 3% of chlorohydrin rubber, and Paraffin oil 9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com