An absorbable biomedical high-strength and corrosion-resistant magnesium alloy material and its preparation method

A biomedical, magnesium alloy technology, applied in the field of magnesium alloy biomaterials, can solve problems such as lumen stenosis, achieve the effects of refinement and uniform distribution, speed up transmission and diffusion, and reduce performance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

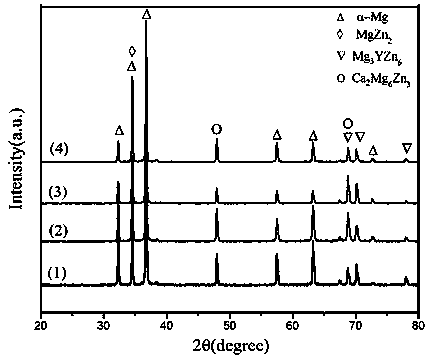

Image

Examples

Embodiment 1

[0035]In the present embodiment, the raw material composition is as follows: Zn 1.00%, Y 1.00%, Zr 0.3%, all the other are Mg and contain a small amount of impurity elements Fe, Ni, Al, Cu, impurity elements are calculated by mass percentage, and each content does not exceed 0.1%, and the total amount shall not exceed 0.4%.

[0036] The preparation method of magnesium alloy in the present embodiment is as follows:

[0037] First, use ZnO and talcum powder paint to evenly brush the inner wall of the self-made non-magnetic stainless steel crucible to white, and preheat the slag removal spoon, stirring spoon, and mold to 200°C; then when the furnace temperature rises to 400°C, put 500g magnesium block Put it into the crucible and continue to heat up to 710°C, keep it warm for 15 minutes to melt the magnesium block; remove the slag when the temperature drops to 700°C, and add 5.2g of Zn block; Add granular pure Y and 5.2gMg-30wt.%Zr master alloy at the same time, stir slightly be...

Embodiment 2

[0042] In this embodiment, the raw material composition is as follows: Zn 5.00%, Y 1.00%, Zr 0.7%, the rest is Mg and contains a small amount of impurity elements Fe, Ni, Al, Cu, impurity elements are calculated by mass percentage, and each content does not exceed 0.1%, and the total amount shall not exceed 0.4%.

[0043] The preparation method of magnesium alloy in the present embodiment is as follows:

[0044] First, use ZnO and talcum powder paint to evenly brush the inner wall of the self-made non-magnetic stainless steel crucible to white, and preheat the slag removal spoon, stirring spoon, and mold to 205°C; then when the furnace temperature rises to 420°C, put 500g magnesium block Put it into the crucible and continue to heat up to 720°C, keep it warm for 20 minutes to melt the magnesium block; remove the slag when the temperature drops to 705°C, and add 27.3g of Zn block; Add granular pure Y and 12.5gMg-30wt.%Zr master alloy at the same time, stir slightly below the l...

Embodiment 3

[0049] In the present embodiment, the raw material composition is as follows: Zn 1.00%, Y 2.00%, Zr 0.4%, the rest is Mg and contains a small amount of impurity elements Fe, Ni, Al, Cu, impurity elements are calculated by mass percentage, each content is different Exceeding 0.1%, the total amount shall not exceed 0.4%.

[0050] The preparation method of magnesium alloy in the present embodiment is as follows:

[0051] First, paint the inner wall of the self-made non-magnetic stainless steel crucible evenly with ZnO and talcum powder to white, and preheat the slag removal spoon, stirring spoon, and mold to 210°C; then when the furnace temperature rises to 430°C, put 500g magnesium block Put it into a crucible and continue to heat up to 715°C, keep it warm for 18 minutes to melt the magnesium block; remove slag when the temperature drops to 710°C, and add 5.2g of Zn block; Add granular pure Y and 6.8gMg-30wt.%Zr master alloy at the same time, stir slightly below the liquid leve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com