A flexible and stretchable multifunctional nanofiber sensor and its preparation method

A nanofiber and nanofiber membrane technology is applied in the field of multifunctional nanofiber sensors and their preparation, and achieves the effects of fast response speed, high electrical conductivity, and simple and easy manufacturing process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

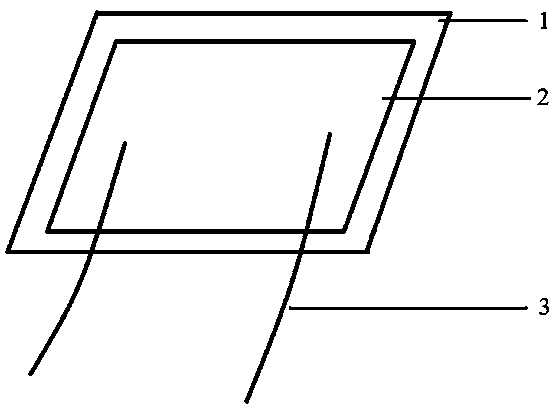

Image

Examples

Embodiment 1

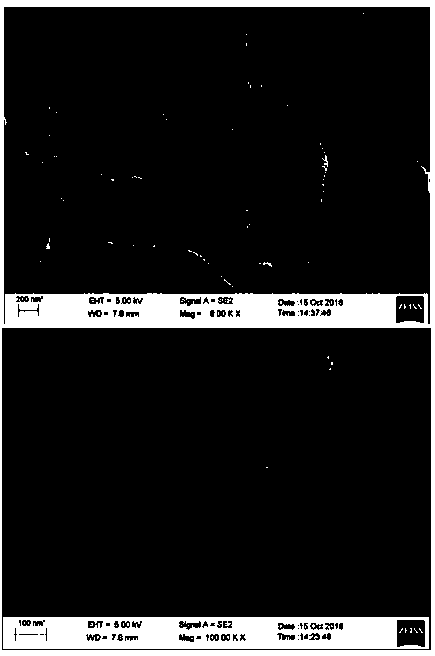

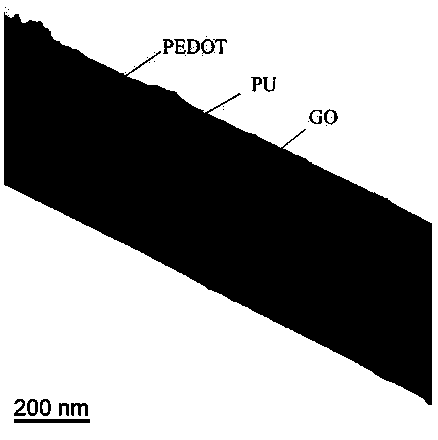

[0029] The preparation method of the flexible and stretchable multifunctional nanofiber sensor of this embodiment is as follows:

[0030] (1) Dimethylformamide and tetrahydrofuran were prepared in a mass ratio of 1:0.3 to obtain a mixed solvent, and graphene oxide powder was added to the mixed solvent, and ultrasonically dispersed for 3 h at room temperature to obtain a uniform mass concentration of 0.2 % graphene oxide solution, then adding molecular weight is 80000 polyurethane particles, magnetic stirring at room temperature for 8 h to obtain a mass concentration of 9% polyurethane solution doped graphene oxide;

[0031] (2) The polyurethane solution doped with graphene oxide obtained in step (1) is used as a spinning solution, transferred to a syringe for electrospinning, and the roller is used as a receiving device to obtain a polyurethane nanofiber membrane doped with graphene oxide , the spinning solution flow rate is 0.5 ml / h, the spinning voltage is 18 kV, and the dis...

Embodiment 2

[0038] The preparation method of the flexible and stretchable multifunctional nanofiber sensor of this embodiment is as follows:

[0039] (1) Dimethylformamide and tetrahydrofuran were prepared as a mixed solvent at a mass ratio of 1:0.5, graphene oxide powder was added to the mixed solvent, and ultrasonically dispersed for 4 h at room temperature to obtain a uniform graphene oxide solution with a mass concentration of 0.4 % , and then add polyurethane particles, and stir magnetically at room temperature for 10 h to obtain a polyurethane solution doped with graphene oxide. The molecular weight of described polyurethane is 100000; The mass concentration of polyurethane is 10%; Of graphene oxide;

[0040] (2) The polyurethane solution doped with graphene oxide obtained in step (1) is used as a spinning solution, transferred to a syringe for electrospinning, and the roller is used as a receiving device to obtain a polyurethane nanofiber membrane doped with graphene oxide . The ...

Embodiment 3

[0046] The preparation method of the flexible and stretchable multifunctional nanofiber sensor of this embodiment is as follows:

[0047] (1) Dimethylformamide and tetrahydrofuran were prepared as a mixed solvent at a mass ratio of 1:0.8, graphene oxide powder was added to the mixed solvent, and dispersed ultrasonically for 5 h at room temperature to obtain a uniform graphene oxide solution. Then polyurethane particles were added, and magnetically stirred for 12 h at room temperature to obtain a polyurethane solution doped with graphene oxide. The molecular weight of described polyurethane is 120000; The mass concentration of polyurethane is 11%; The mass concentration of graphene oxide is 0.6%;

[0048] (2) The polyurethane solution doped with graphene oxide obtained in step (1) is used as a spinning solution, transferred to a syringe for electrospinning, and the roller is used as a receiving device to obtain a polyurethane nanofiber membrane doped with graphene oxide . The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com