Preparation method and application of porous carbon material co-doped with N, S and P

A porous carbon material and co-doping technology, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve the problem of large equivalent series resistance of battery components, lower performance, lower energy storage efficiency and cycle life, etc. problem, to achieve the effect of abundant raw materials and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

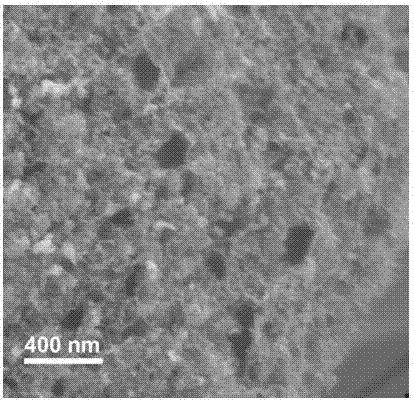

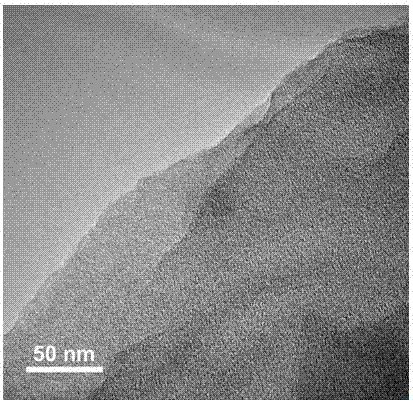

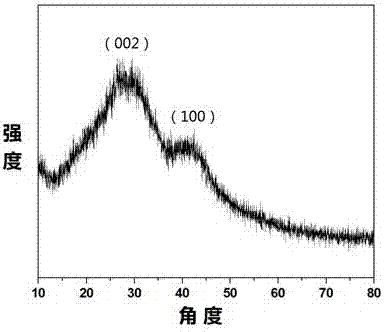

Image

Examples

Embodiment 1

[0029] (1) Carbonization: Take the dried honeycomb raw material in a quartz crucible and heat it in a tube furnace. In a nitrogen-enclosed environment, raise the temperature to 400°C at a heating rate of 5°C / min. The carbonization time is 1 h, then cool down. After cooling to normal temperature, take it out to obtain a black honeycomb carbonized material and pulverize it to obtain a honeycomb carbonized powder.

[0030] (2) Impregnation: According to the alkali-carbon ratio of 5:1, weigh 10g of KOH in a beaker, then weigh 2g of honeycomb carbonized material and mix it, add an appropriate amount of distilled water, stir to mix evenly, and then place it in an oven at 100°C for drying , Obtain honeycomb carbonized powder impregnated with KOH.

[0031] (3) Activation: The honeycomb carbonized powder impregnated with KOH was placed in a nickel crucible and placed in a tube furnace. The mixture was heated to 700 °C at a rate of 5 °C / min under a nitrogen atmosphere and then kept for ...

Embodiment 2

[0034] (1) Carbonization: Take the dried honeycomb raw material in a quartz crucible and heat it in a tube furnace. In a nitrogen-enclosed environment, raise the temperature to 400°C at a heating rate of 5°C / min. The carbonization time is 1 h, then cool down. After cooling to normal temperature, take it out to obtain a black honeycomb carbonized material and pulverize it to obtain a honeycomb carbonized powder.

[0035] (2) Impregnation: According to the alkali-carbon ratio of 5:1, weigh 10g of KOH in a beaker, then weigh 2g of honeycomb carbonized material and mix it, add an appropriate amount of distilled water, stir to mix evenly, and then place it in an oven at 100°C for drying , Obtain honeycomb carbonized powder impregnated with KOH.

[0036] (3) Activation: The honeycomb carbonized powder impregnated with KOH was placed in a nickel crucible and placed in a tube furnace. The mixture was heated to 800 °C at a rate of 5 °C / min under a nitrogen atmosphere and then kept for ...

Embodiment 3

[0039] (1) Carbonization: Take the dried honeycomb raw material in a quartz crucible and heat it in a tube furnace. In a nitrogen-enclosed environment, raise the temperature to 400°C at a heating rate of 5°C / min. The carbonization time is 1 h, then cool down. After cooling to normal temperature, take it out to obtain a black honeycomb carbonized material and pulverize it to obtain a honeycomb carbonized powder.

[0040] (2) Impregnation: According to the alkali-carbon ratio of 5:1, weigh 10g of KOH in a beaker, then weigh 2g of honeycomb carbonized material and mix it, add an appropriate amount of distilled water, stir to mix evenly, and then place it in an oven at 100°C for drying , Obtain honeycomb carbonized powder impregnated with KOH.

[0041](3) Activation: The honeycomb carbonized powder impregnated with KOH was placed in a nickel crucible and placed in a tube furnace. The mixture was heated to 900 °C at a rate of 5 °C / min under nitrogen atmosphere and then kept for 2 h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com