Pyridine coordinated copper heterogeneous catalyst and preparation method thereof

A heterogeneous catalyst and catalyst technology, applied in the preparation of carbon monoxide and oxygen, organic compound/hydride/coordination complex catalysts, chemical instruments and methods, etc., can solve the problems of difficult separation and recovery, equipment corrosion, and the amount of organic ligands fed Large and other problems, to achieve the effect of overcoming the large amount of feeding and easy separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

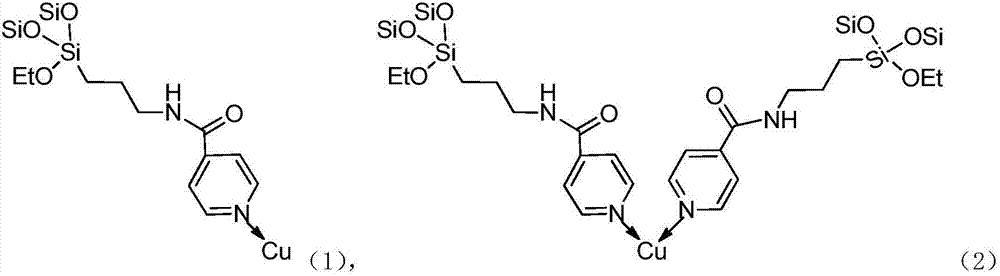

[0023] Dissolve 3.5mL of 3-aminopropyltriethoxysilane and 1.33mL of pyridine in 80mL of dry diethyl ether for later use. Another 2.67g of pyridine-2-formyl chloride hydrochloride was dissolved in 140mL of dry diethyl ether, under a nitrogen atmosphere, under continuous stirring, the diethyl ether solution of aminopropyltriethoxysilane and pyridine was added, and after reacting at room temperature for 21h, the The reaction mixture was filtered to remove solids, and the mother liquor was rotovapped to give a pale yellow oil.

[0024] The product obtained in Step 1 and 3.0 g of dry nano-silica (50 nm in diameter) were heated to 120° C. in 50 mL of dry toluene solvent under the protection of nitrogen, and refluxed for 24 h. After cooling to room temperature, filter and wash the filter cake with toluene several times, and dry the solid in vacuum for 3-5 hours to obtain pyridine-modified silica.

[0025] Dissolve 1.3427g (0.007mol) CuI in 30mL of acetonitrile, add 1.6125g of surfac...

Embodiment 2

[0028] Take 3.000g of dry nano-silica (50nm diameter) and 3.5mL of 3-aminopropyltriethoxysilane into 50mL of dry toluene, keep stirring and heating to 120°C under nitrogen protection, and reflux for 24h. After cooling, the reaction mixture was separated by filtration, and the filter cake was washed three times with 150 mL of toluene, and the solid was vacuum-dried at 50° C. for 3 h to obtain surface-aminated silica.

[0029]In a nitrogen atmosphere, mix 2.5g of pyridine-2-formyl chloride hydrochloride and 2.34g of surface-aminated silicon dioxide in 50mL of dry toluene, add 15mL of triethylamine under stirring, and reflux overnight at 120°C. Cool to room temperature, filter, and wash the filter cake with water and toluene several times, and dry the solid in vacuum for 3-5 hours to obtain pyridine-modified silica.

[0030] Dissolve 2.228 g of CuI in 50 mL of acetonitrile, add the surface-modified pyridine silica obtained in step 2, and stir and reflux for 24 h under nitrogen pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com