Preparation method of gamma-copper iodide

A technology of cuprous iodide and copper flakes, which is applied in the field of preparation of γ-cuprous iodide, can solve the problems of decreased iodine utilization rate, difficulty in product separation, waste of iodine resources, etc., and achieves easy control of reaction conditions and particle size distribution. Uniform, yield-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0018] A preparation method of nanometer gamma-cuprous iodide, the steps are as follows:

[0019] (1) Preparation of iodine solution: Dissolve 0.51g of iodine elemental substance in a round-bottomed flask filled with 2g of 1-butyl 3-methylimidazolium tetrafluoroborate ionic liquid, seal the round-bottomed flask and place the round-bottomed flask The internal ionic liquid is heated to 100°C, and maintained at 100°C for a period of time until the iodine element is completely dissolved to obtain an iodine solution;

[0020] (2) Preparation of cuprous iodide: Put the polished copper sheet (about 0.38g) into the iodine solution, continue to control the temperature at 100°C and heat and stir until the color of the solution becomes colorless, cool to room temperature, and take out the bottom of the solution The precipitate was washed with deionized water and ethanol several times, and dried in vacuum to obtain 0.750 g of white γ-cuprous iodide, with a yield of 98.1%.

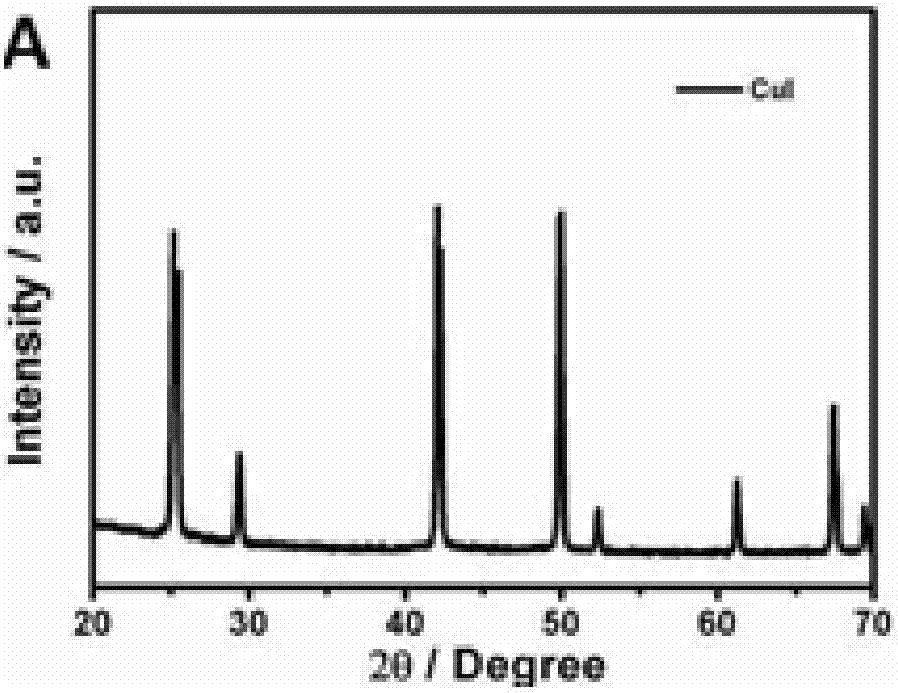

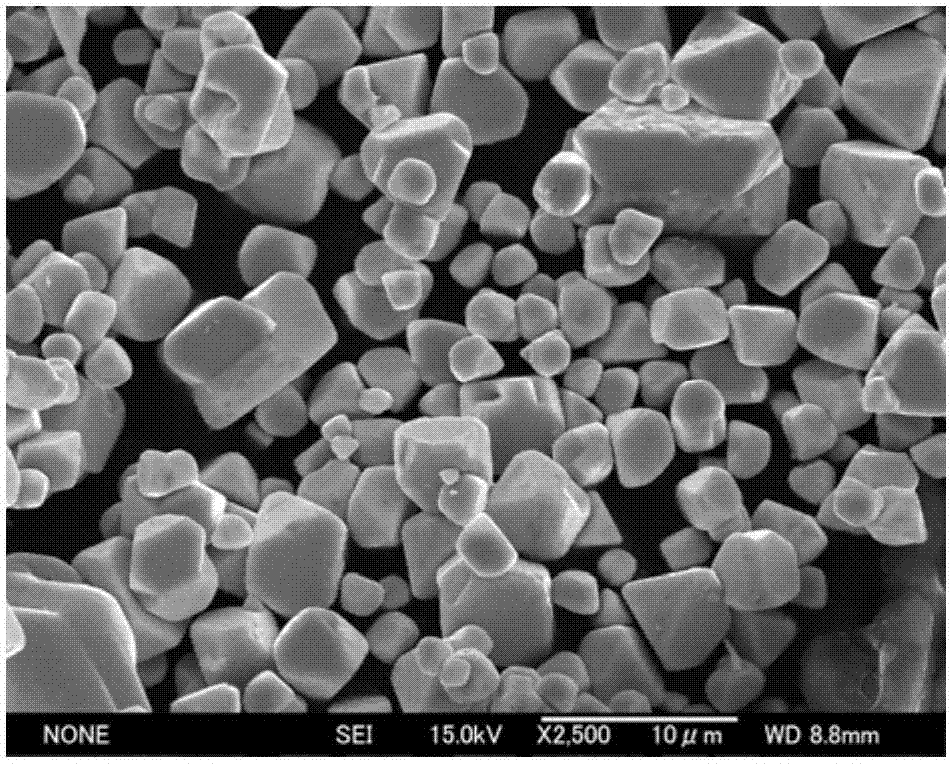

[0021] Depend...

example 2

[0023] A preparation method of gamma-cuprous iodide, the steps are as follows:

[0024] (1) Preparation of iodine solution: Dissolve 0.51g of iodine elemental substance in a round-bottomed flask filled with 2g of 1-butyl 3-methylimidazolium tetrafluoroborate ionic liquid, seal the round-bottomed flask and place the round-bottomed flask The internal ionic liquid is heated to 150°C, and maintained at 150°C for a period of time until the elemental iodine is completely dissolved to obtain an iodine solution;

[0025] (2) Preparation of cuprous iodide: Put the polished copper sheet (about 0.38g) into the iodine solution, continue to control the temperature at 150°C and heat and stir until the color of the solution becomes colorless, cool to room temperature, and take out the bottom of the solution The precipitate was washed with deionized water and ethanol several times, and vacuum-dried to obtain 0.755 g of white nanometer γ-cuprous iodide, and the yield of the product was 98.7%. ...

example 3

[0027] A preparation method of gamma-cuprous iodide, the steps are as follows:

[0028] (1) Preparation of iodine solution: Dissolve 0.51g of iodine elemental substance in a round-bottomed flask filled with 2g of 1-butyl 3-methylimidazolium hexafluorophosphate ionic liquid, seal the round-bottomed flask and place in the round-bottomed flask The ionic liquid is heated to 80°C and maintained at 80°C for a period of time until the iodine element is completely dissolved to obtain an iodine solution;

[0029] (2) Preparation of cuprous iodide: Put the polished copper sheet (about 0.38g) into the iodine solution, continue to control the temperature at 80°C and heat and stir until the color of the solution becomes colorless, cool to room temperature, and take out the bottom of the solution The precipitate was washed with deionized water and ethanol several times, and vacuum-dried to obtain 0.745 g of white γ-cuprous iodide, with a yield of 97.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com