Preparation method of novel reticulate structure capsule wall microcapsule phase-change material

A network structure, phase change material technology, applied in microcapsule preparations, microsphere preparation, heat exchange materials, etc. Leakage, improved density and stability, less cracking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] A method for preparing the phase change material of the above-mentioned novel net-like capsule wall microcapsules, characterized in that it comprises the following steps:

[0030] Step 1, weighing the capsule core component and polyisocyanate and mixing to form the first solution;

[0031] Weigh the raw materials according to the mass ratio of the polyisocyanate to the capsule core component being 0.05-0.40:1; mix the capsule core component and the polyisocyanate at a temperature 5-20°C higher than the melting point of the capsule core component to form the first a solution.

[0032] The capsule core component is aliphatic hydrocarbon or fatty acid ester compound, preferably n-tetradecane, n-octadecane or butyl stearate, the polyisocyanate is aliphatic diisocyanate, and the polyisocyanate is preferably isocyanate Phorne diisocyanate.

[0033] Step 2, configure the emulsion;

[0034] Measure the emulsifier according to the mass ratio of the emulsifier to the capsule c...

Embodiment 1

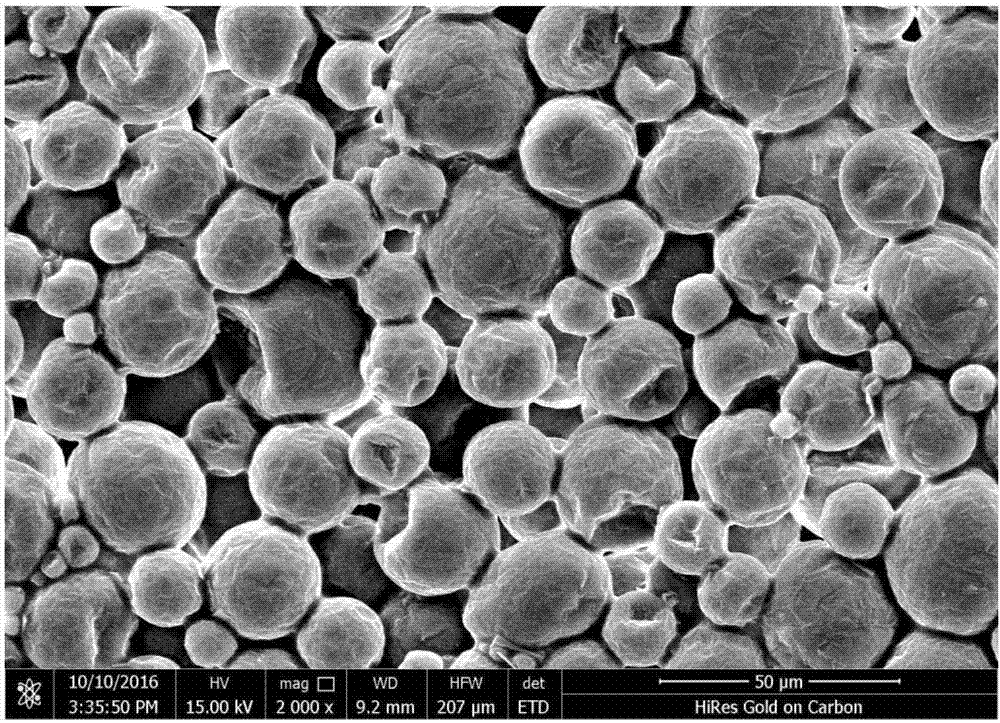

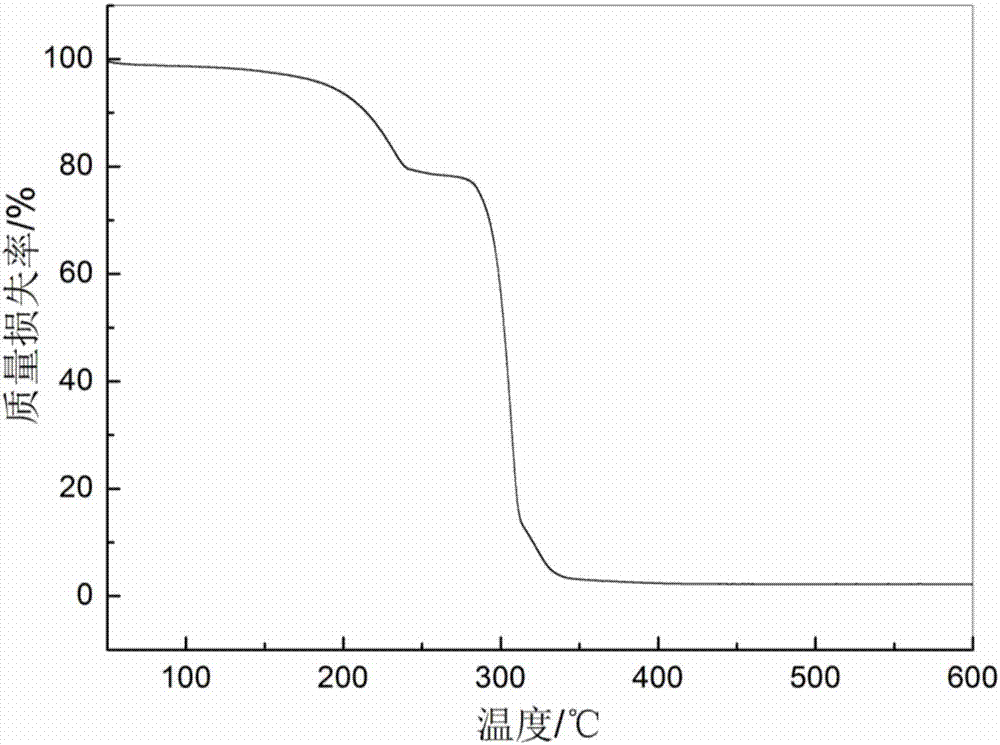

[0042] The invention relates to a new phase-change material of capsule wall microcapsule with network structure, which includes two parts of capsule core material and outer capsule wall. Its core material is n-tetradecane, its shell has a network structure, and the capsule wall is a polyurethane polymer with a network structure formed by the polymerization of dibasic isocyanate, polyamine compounds and polyol compounds. .

[0043] Wherein, polyamine compounds refer to aliphatic diamines or polyamines, preferably diethylenetriamine.

[0044] Among them, the polyol compound is a polyol containing three or more hydroxyl groups, preferably pentaerythritol containing four hydroxyl groups.

[0045] A method for preparing the phase change material of the above-mentioned novel net-like capsule wall microcapsules, characterized in that it comprises the following steps:

[0046] Step 1, weighing the capsule core component and polyisocyanate and mixing to form the first solution;

[0...

Embodiment 2

[0058] The invention relates to a new phase-change material of capsule wall microcapsule with network structure, which includes two parts of capsule core material and outer capsule wall. Its core material is n-octadecane, its shell is a network structure, and the capsule wall is a polyurethane polymer with a network structure capsule wall formed by the polymerization of dibasic isocyanate, polyamine compounds and polyol compounds. thing.

[0059] Wherein, polyamine compounds refer to aliphatic diamines or polyamines, preferably diethylenetriamine.

[0060] Among them, the polyol compound is a polyol containing three or more hydroxyl groups, preferably pentaerythritol containing four hydroxyl groups.

[0061] A method for preparing the phase change material of the above-mentioned novel net-like capsule wall microcapsules, characterized in that it comprises the following steps:

[0062] Step 1, weighing the capsule core component and polyisocyanate and mixing to form the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com