High-quality inorganic perovskite film, preparation method thereof and application of high-quality inorganic perovskite film to solar cells

A technology for solar cells and inorganic calcium, applied in the field of solar cells, can solve the problems of affecting the photoelectric conversion performance of the thickness of the inorganic perovskite thin film, unable to prepare a precursor solution, unable to prepare a thin film, etc., so as to improve the short-circuit current density and the preparation steps are simple. , the effect of improving solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] Preparation of High Quality Inorganic Perovskite Thin Films

[0069] Choose PbI 2 and CsBr are inorganic perovskite material precursor raw materials, according to 0.67mmol PbI 2 and 0.67 mmol CsBr were dissolved in 1 ml of a mixed solvent of DMF and DMSO, wherein the volume ratio of DMF and DMSO was 9:1, stirred for 2 h, and a solution with a concentration of 0.67 mol / L of the inorganic perovskite precursor solution was prepared.

[0070] The above solution was uniformly coated on the FTO glass substrate, and spin-coated at a speed of 1500rpm for 30s to obtain a colorless and transparent film.

[0071] Transfer the above film to a hot stage at 70°C for 3 minutes for annealing, the film turns yellowish brown, then transfer to a hot stage at 290°C for annealing for 10 minutes, remove and cool to prepare a high-quality inorganic perovskite film.

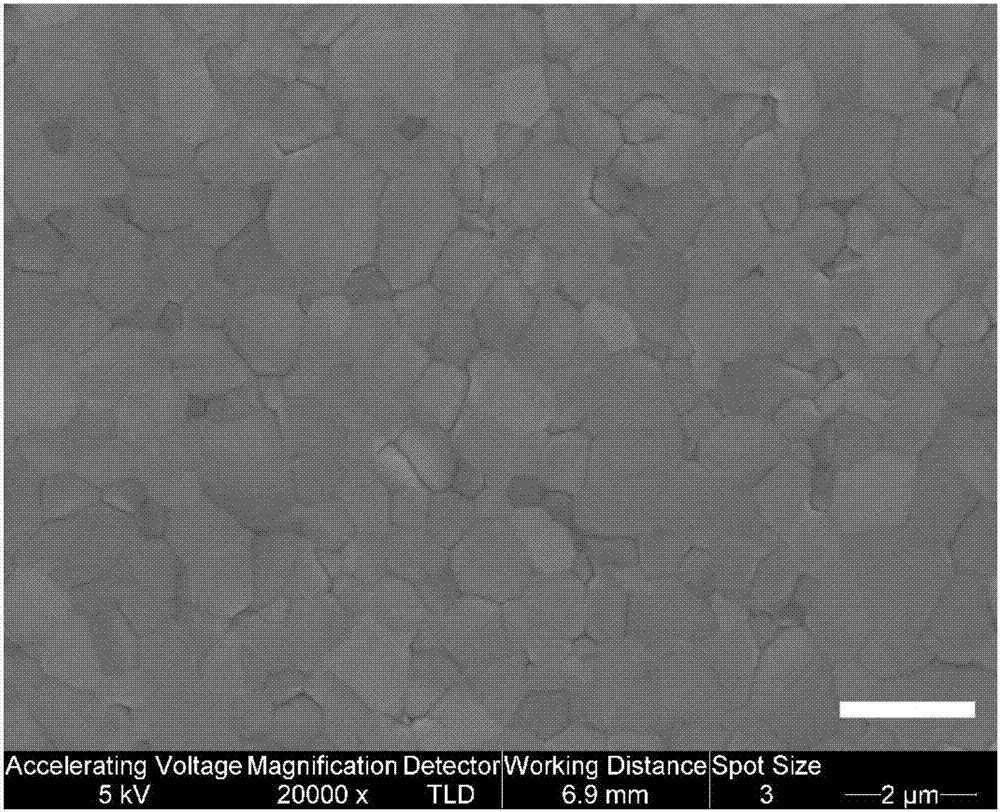

[0072]The thickness of the high-quality inorganic perovskite film prepared in this embodiment is 400nm-450nm.

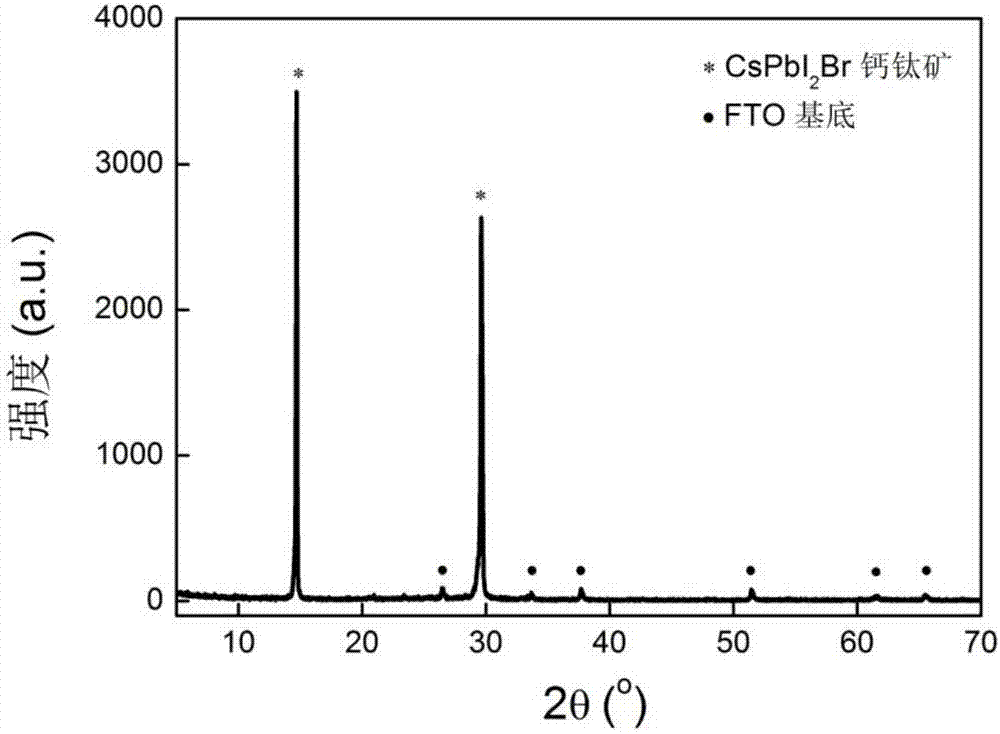

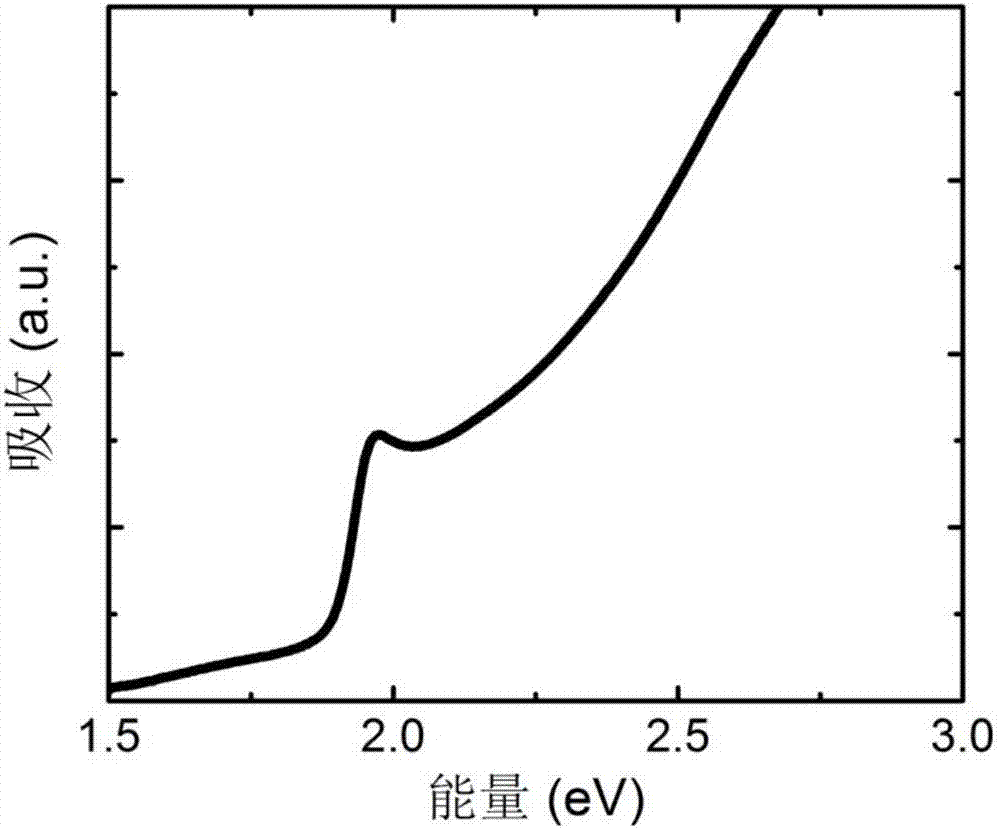

[0073] figu...

Embodiment 2

[0078] Preparation and performance testing of solar cell devices with high-quality perovskite thin films

[0079] Using spray pyrolysis technology, the volume ratio of spray pyrolysis is 1:1 on the clean commercial transparent conductive substrate FTO (the thickness of the coating is about 450nm~500nm, the sheet resistance of the substrate is about 14Ω / □, and the light transmittance is 90%). Mixed precursor solution of titanium isopropoxybisacetylacetonate and ethanol. Then sintered at 500°C for 60 minutes to form TiO 2 dense layer.

[0080] According to the method described in Example 1, a high-quality perovskite film was prepared on the above substrate as an absorbing layer.

[0081] A hole transport layer P3HT was prepared on the perovskite thin film (absorber layer) using a spin coating method.

[0082] A gold layer with a thickness of 80 nm was prepared as the top electrode of the device by vacuum thermal evaporation method.

[0083] A 450W Model 91150 instrument from...

Embodiment 3

[0086] Preparation of High Quality Inorganic Perovskite Thin Films

[0087] The preparation method is the same as in Example 1, except that the volume ratio of DMSO and DMF in the mixed solvent of DMSO and DMF is 1:3.

[0088] Preparation and performance testing of high-quality perovskite thin film solar cell devices.

[0089] The preparation method is the same as in Example 2.

[0090] The photoelectric conversion efficiency of the solar cell of the perovskite thin film prepared in this example is 6.86%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com