Alcohol-free fountain solution and preparation method thereof

A fountain solution and alcohol-free technology, which is applied in the field of alcohol-free fountain solution and its preparation, can solve the problems of insufficient dampening ability, flammability and explosion, poor wetting performance of fountain solution, etc., and achieve printing efficiency and quality Improve and reduce VOC emissions, not easy to spoil and deteriorate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

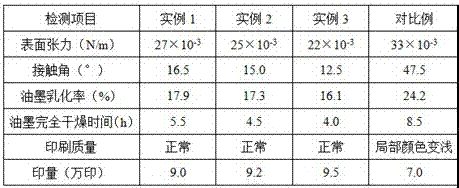

Examples

example 1

[0024] Take 8g of gelatin, 10g of methylcellulose, and 5g of polyethylene glycol, add them into 1L of deionized water, and stir at 300r / min for 20min to obtain a colloidal solution, then take 80g of cornstarch, add them to 160mL of ethylene glycol, and Min stirred for 15 minutes, then added 5 mL of sulfuric acid solution with a mass fraction of 98%, continued to stir for 20 minutes, added 80 g of n-dodecyl alcohol, 1.8 g of p-toluenesulfonic acid, and heated to 110 ° C, stirred for 4 h, then cooled to 70 ° C, And let it stand for 2 hours, then adjust the pH of the mixed solution to 8.0 with a mass fraction of 3% sodium hydroxide solution, and then distill under reduced pressure to obtain starch-based dodecyl glucoside. Take 10g sodium lauryl sulfate, 300g cetyl alcohol , 500g of 1,2-propanediol, stirred at 300r / min for 15min, then added 0.8g of sodium chloride, 15g of starch-based dodecyl glucoside, 1g of Casson fungicidal preservative DL104, 1g of antifoaming agent BYK-019, at...

example 2

[0026] Take 9g of gelatin, 11g of methylcellulose, and 7g of polyethylene glycol, add them to 1L of deionized water, and stir at 350r / min for 25min to obtain a colloidal solution, then take 90g of konjac starch, add it to 170mL of ethylene glycol, and min and stirred for 18 minutes, then added 5 mL of sulfuric acid solution with a mass fraction of 98%, and continued to stir for 25 minutes, then added 90 g of n-dodecyl alcohol and 1.9 g of p-toluenesulfonic acid, and heated to 115 ° C, stirred for 4 h, then cooled to 75 ° C, And let it stand for 2 hours, then use 3% sodium hydroxide solution to adjust the pH of the mixed solution to 8.3, then distill under reduced pressure to obtain starch-based dodecyl glucoside, take 11g sodium lauryl sulfate, 350g cetyl alcohol , 550g of 1,2-propanediol, stirred at 400r / min for 18min, then added 1.3g of sodium chloride, 18g of starch-based dodecyl glucoside, 2g of Kasson antiseptic preservative DL104, 2g of antifoaming agent BYK-019, at 1000r...

example 3

[0028]Take 10g of gelatin, 12g of methylcellulose, and 8g of polyethylene glycol, add them into 2L of deionized water, and stir at 400r / min for 30min to obtain a colloidal solution, then take 100g of plant starch, add it to 180mL of ethylene glycol, and min and stirred for 20 min, then added 6 mL of sulfuric acid solution with a mass fraction of 98%, and continued to stir for 30 min, then added 100 g of n-dodecyl alcohol and 2.0 g of p-toluenesulfonic acid, and heated to 120 ° C, stirred for 5 h, then cooled to 80 ° C, And let it stand for 3 hours, and then adjust the pH of the mixed solution to 8.5 with a mass fraction of 3% sodium hydroxide solution, and then distill under reduced pressure to obtain starch-based dodecyl glucoside, take 12g sodium lauryl sulfate, 400g cetyl alcohol , 600g of 1,2-propanediol, stirred at 500r / min for 20min, then added 1.8g of sodium chloride, 20g of starch-based dodecyl glucoside, 3g of Casson fungicidal preservative DL104, 3g of defoamer BYK-01...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com