Preparation method for lithium ion battery cathode material ferric niobate

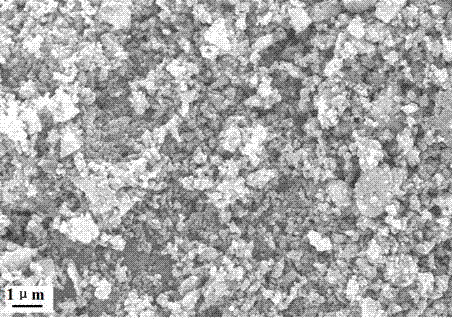

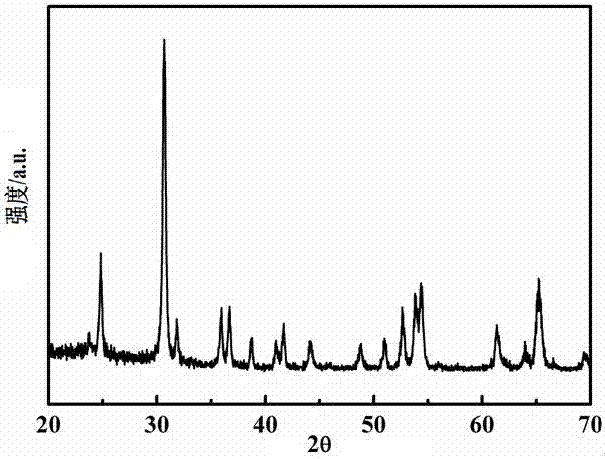

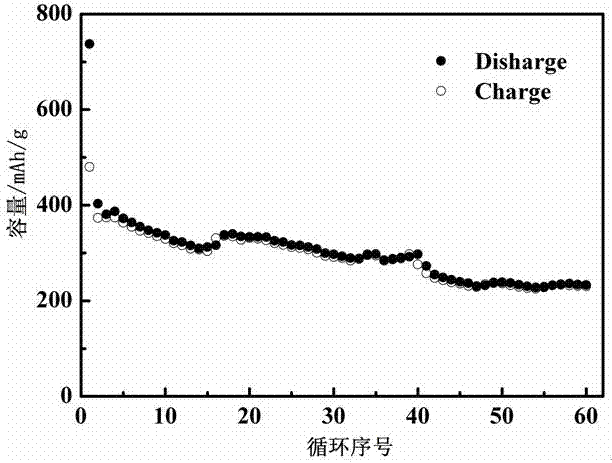

A technology of lithium ion battery and negative electrode material, applied in the field of lithium ion battery materials and electrochemistry, can solve the problems of complex synthesis method, increase production cost, low capacity, etc., and achieve the effect of excellent electrochemical performance, uniform and fine particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Take 0.814g NbCl 5 Dissolve in the dehydrated ethanol of 40ml in the anaerobic anhydrous environment of glove box, then transfer to outside the box and stir evenly, then take 1.217g of Fe(NO 3 ) 3 9H 2 O was added to the niobium metal solution and continued to stir for 2h. Aqueous ammonia was added dropwise to the above solution at a rate of 0.5 ml / min using a peristaltic pump, and the pH was adjusted to 9 while stirring continuously.

[0022] After the dropwise addition, the obtained suspension was continuously stirred for more than 12 hours, then filtered with a centrifuge, and washed with deionized water for more than 5 times. The precipitated substance obtained by filtering is dried in a vacuum oven at 80° C. for more than 8 hours, and then ground to obtain the precursor.

[0023] Take the ground precursor hydroxide and place it in a tube furnace for calcination at 900°C for 6 hours. After taking it out, the powder sample obtained by grinding is the target produ...

Embodiment 2

[0027] Take 1.221g NbCl 5 Dissolve in 60ml of absolute ethanol in the anaerobic and anaerobic environment of the glove box, then transfer to the outside of the box and stir evenly, then take 1.826g of Fe(NO 3 ) 3 9H 2 O was added to the niobium metal solution and continued to stir for 2h. Aqueous ammonia was added dropwise to the above solution at 1.0 ml / min by a peristaltic pump, and the pH was adjusted to 9.5 while stirring continuously.

[0028] After the dropwise addition, the obtained suspension was continuously stirred for more than 8 hours, then filtered with a centrifuge, and washed with deionized water for more than 5 times. The precipitated substance obtained by filtering is dried in a vacuum oven at 80° C. for more than 8 hours, and then ground to obtain the precursor.

[0029] Take the ground precursor hydroxide and place it in a tube furnace for calcination at 900°C for 6 hours. After taking it out, the powder sample obtained by grinding is the target product....

Embodiment 3

[0032] Take 1.628g NbCl 5 Dissolve in the dehydrated ethanol of 80ml in the anaerobic and anaerobic environment of glove box, then transfer to outside the box and stir evenly, then take 2.434g of Fe(NO 3 ) 3 9H 2 O was added to the niobium metal solution and continued to stir for 2h. Aqueous ammonia was added dropwise to the above solution at 0.8 ml / min by a peristaltic pump, and the pH was adjusted to 9.2 while stirring continuously.

[0033] After the dropwise addition, the obtained suspension was continuously stirred for more than 16 hours, then filtered with a centrifuge, and washed with deionized water for more than 5 times. The precipitated substance obtained by filtering is dried in a vacuum oven at 80° C. for more than 8 hours, and then ground to obtain the precursor.

[0034] Take the ground precursor hydroxide and place it in a tube furnace for calcination at 900°C for 6 hours. After taking it out, the powder sample obtained by grinding is the target product.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Initial discharge capacity | aaaaa | aaaaa |

| Initial discharge capacity | aaaaa | aaaaa |

| Initial discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com