Preparation method and application of cobalt oxide/mesoporous carbon composite material electrochemical sensor

A composite material, graphitized mesoporous carbon technology, applied in the fields of material electrochemical variables, scientific instruments, analytical materials, etc., can solve the problems of low sensitivity and selectivity, expensive instruments, complicated sample preparation, etc. Simple operation and small size of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

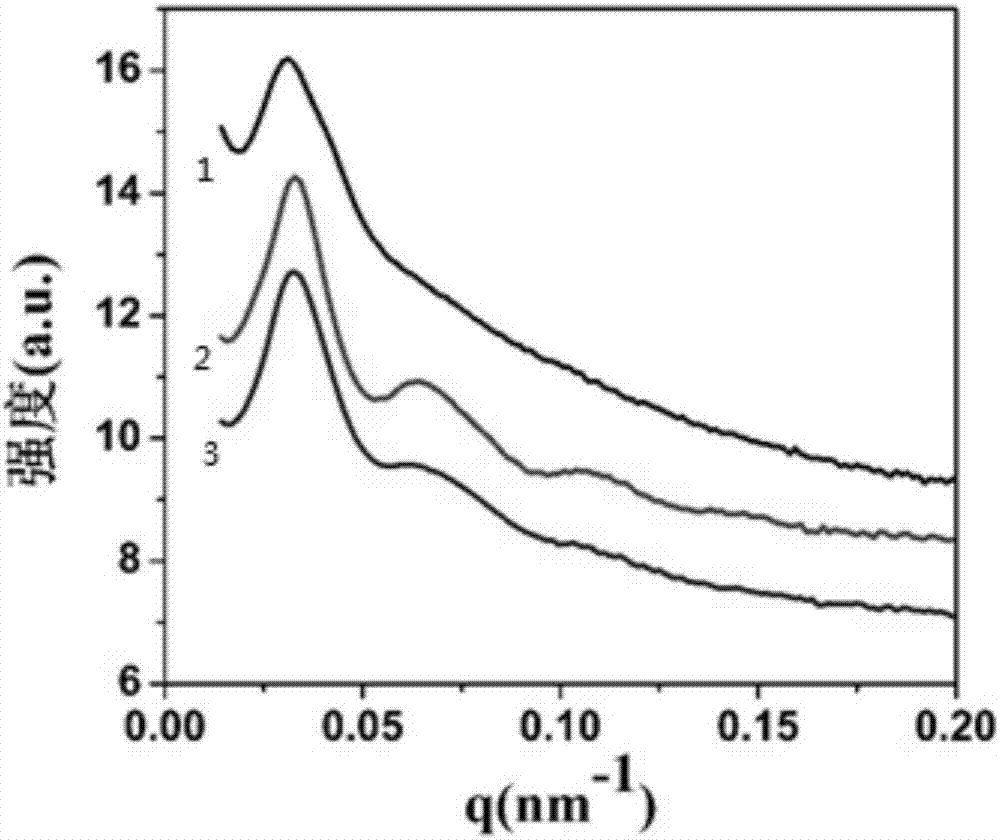

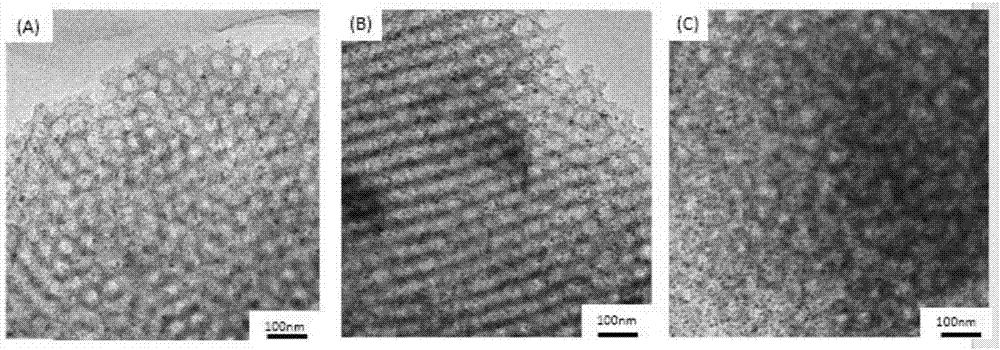

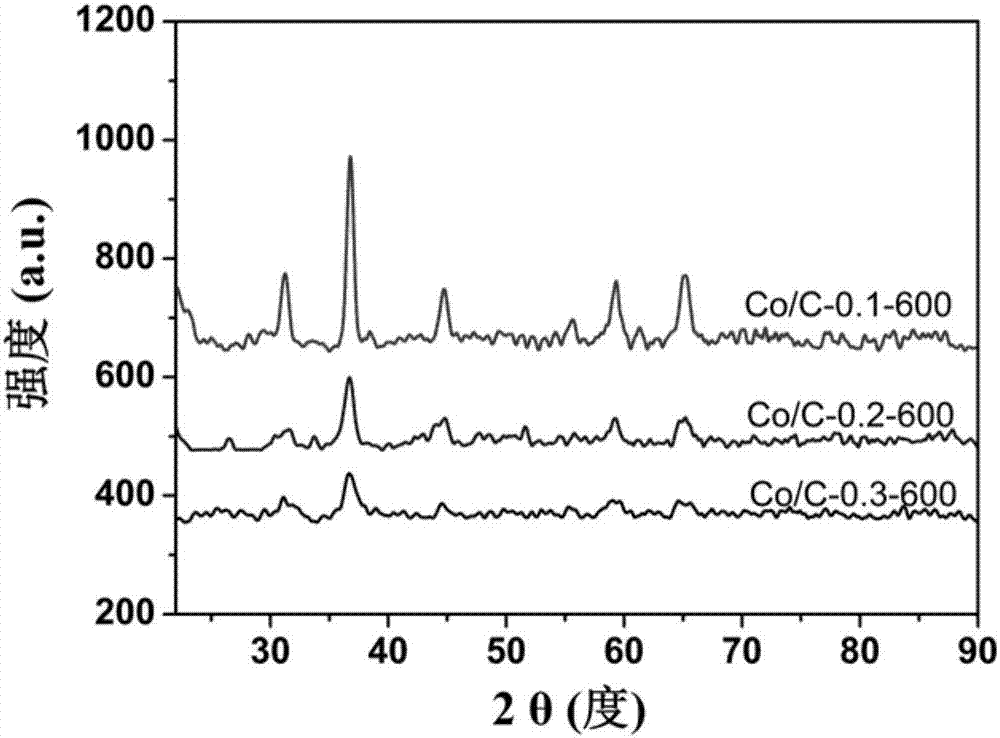

[0032] Example 1 Synthesis of Cobalt Oxide Particles and Graphitized Ordered Mesoporous Carbon Nanocomposites

[0033] Take 0.06g of cobalt nitrate hexahydrate and dissolve it in 2ml of pre-prepared phenolic resin solution, stir for 0.5h, and mark it as liquid A. 0.1g PS-b-PEO was dissolved in 5ml THF to make solution B. Add B dropwise to A and stir at room temperature for 2h. The resulting dark purple solution was transferred to a petri dish and evaporated at room temperature for 2 h. It was then transferred to a 50°C oven for 24 hours, and then the oven temperature was further raised to 100°C for 24 hours. Finally, a light yellow transparent composite film was obtained on a watch glass. The film was scraped off from the petri dish with a single-blade knife, placed in a tube furnace, and baked at 600°C for 3 hours under a nitrogen atmosphere, with a heating rate of 1.0°C / min. Obtain a black sample, named as Co / C-0.1-600, wherein 0.1 represents the concentration of the phe...

Embodiment 2

[0034] Example 2 Synthesis of Cobalt Oxide Particles and Graphitized Ordered Mesoporous Carbon Nanocomposites

[0035] Take 0.12g of cobalt nitrate hexahydrate and dissolve it in 2ml of pre-prepared phenolic resin solution, stir for 0.5h, and mark it as liquid A. 0.1g PS-b-PEO was dissolved in 5ml THF to make solution B. Add B dropwise to A and stir at room temperature for 2h. The resulting dark purple solution was transferred to a petri dish and evaporated at room temperature for 2 h. It was then transferred to a 50°C oven for 24 hours, and then the oven temperature was further raised to 100°C for 24 hours. Finally, a light yellow transparent composite film was obtained on a watch glass. The film was scraped off from the petri dish with a single-blade knife, placed in a tube furnace, and baked at 600°C for 3 hours under a nitrogen atmosphere, with a heating rate of 1.0°C / min. Obtain a black sample, named as Co / C-0.2-600, where 0.2 represents the concentration of the phenoli...

Embodiment 3

[0036] Example 3 Synthesis of cobalt oxide particles and graphitized ordered mesoporous carbon nanocomposites 0.35 g of cobalt nitrate hexahydrate was dissolved in 4 ml of pre-prepared phenolic resin solution and stirred for 0.5 h, marked as liquid A. 0.1g PS-b-PEO was dissolved in 5ml THF to make solution B. Add B dropwise to A and stir at room temperature for 2h. The resulting dark purple solution was transferred to a petri dish and evaporated at room temperature for 2 h. It was then transferred to a 50°C oven for 24 hours, and then the oven temperature was further raised to 100°C for 24 hours. Finally, a light yellow transparent composite film was obtained on a watch glass. The film was scraped off from the petri dish with a single-blade knife, placed in a tube furnace, and baked at 600°C for 3 hours under a nitrogen atmosphere, with a heating rate of 1.0°C / min. Obtain a black sample, named Co / C-0.3-600, wherein 0.3 represents the concentration of the phenolic resin solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com