Upgrading and purifying method of raisin extract and application of raisin extract

A purification method and raisin technology, which is applied in the field of quality improvement and purification of raisin extract, can solve the problems of insufficient sweetness, poor comfort, weak aroma, etc., and achieve the effect of good activity retention, mild conditions, and convenient cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

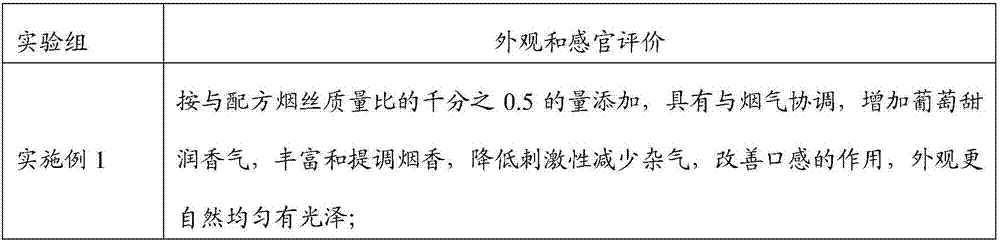

Embodiment 1

[0026] A method for upgrading and purifying raisin extract and its application, specifically comprising the following steps:

[0027] (1) Pretreatment of raisins: freeze the raisins in a -18°C freezer for 15 minutes, crush them with a grinder, and obtain frozen crushed raisins;

[0028] (2) Hydrolysis and fermentation: Mix the frozen pulverized raisins and water at a mass ratio of 1:20, add biological agents (α-L-rhamnopyranosidase, Kluyveromyces lactis powder, according to the mass ratio of 0.3: 0.6, the enzyme activity of α-L-rhamnopyranosidase is 1000u / g, the quality of the biological preparation is 0.1% of the mass of frozen and pulverized raisins), stir evenly, and incubate and hydrolyze and ferment at pH 5 and 40°C for 3.5h , to obtain raisin fermented liquid a;

[0029] (3) Extraction: Extract the raisin fermentation liquid a in step 2) in a constant temperature water bath at 92°C for 2 times, suction and filter under reduced pressure, combine the filtrates, concentrat...

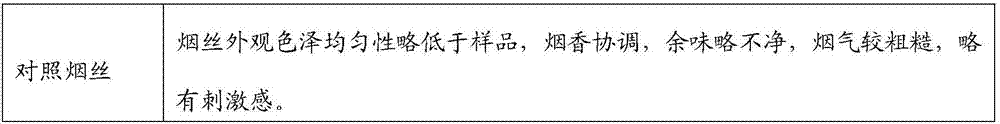

Embodiment 2

[0035] A method for upgrading and purifying raisin extract and its application, specifically comprising the following steps:

[0036] (1) Pretreatment of raisins: freeze the raisins in a -18°C freezer for 20 minutes, crush them with a grinder, and obtain frozen crushed raisins;

[0037] (2) Hydrolysis and fermentation: Mix the frozen pulverized raisins and water at a mass ratio of 1:30, add biological agents (endoprotease, Kluyveromyces lactis, configure according to the mass ratio of 0.5:1, and the endoprotease is food grade, the enzyme activity is 100,000 u / g, the quality of the biological preparation is 0.2% of the mass of frozen and pulverized raisins), stirred evenly, incubated and hydrolyzed and fermented at pH 4.5 and 45°C for 5 hours to obtain raisin fermentation liquid a;

[0038] (3) Extraction: extract the raisin fermentation liquid a from the above step 2) in a constant temperature water bath at 93°C for 2 times, suction and filter under reduced pressure, combine t...

Embodiment 3

[0044] A method for upgrading and purifying raisin extract and its application, specifically comprising the following steps:

[0045] (1) Pretreatment of raisins: freeze the raisins in a -18°C freezer for 25 minutes, crush them with a grinder, and obtain frozen crushed raisins;

[0046] (2) Hydrolysis and fermentation: mix the mass ratio of raisin frozen pulverized matter and water at 1:40, add biological agents (α-L-rhamnopyranosidase, endoprotease, Kluyveromyces lactis, Ratio 0.3:0.6:1.2, the mass of the biological preparation is 0.3% of the mass of frozen crushed raisins), stirred evenly, incubated at pH 4.5, 30°C for 4 hours, and at 45°C for 2 hours to obtain raisins fermented liquid a;

[0047] (3) Extraction: reflux extraction in a constant temperature water bath at 90-95°C for 1-3 times, suction filtration under reduced pressure, combined filtrate, concentrated under reduced pressure to raisin fermented extract with a relative density of 1.1-1.3, and added raisin ferme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com