Continuous production process of atrazine

A technology of atrazine and production process, applied in the field of chemical synthesis and continuous production of atrazine, can solve the problem that it is difficult to meet the needs of customers for high-quality products, not suitable for industrialized large-scale production applications, and product quality fluctuations Large and other problems, to achieve the effect of controllable product particle size, reduced labor intensity, and good production stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

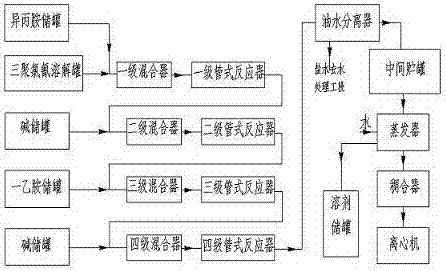

Image

Examples

Embodiment 1

[0024] (1) Add quantitative cyanuric chloride and 10 times the mass of toluene to the cyanuric chloride dissolving tank, stir and dissolve at -10~-5°C, and obtain a homogeneous solution for later use;

[0025] (2) Control the flow rate of cyanuric chloride solution at 10T / h, and the flow rate of isopropylamine (99.6% content) at 0.29T / h, and pump them into the first-stage single-group static mixer respectively, and enter the first-stage after mixing Fully react in the tubular reactor, then accurately pump the 15% sodium hydroxide aqueous solution into the second-stage single-group static mixer at a flow rate of 1.32T / h, and mix it with the output liquid from the first-stage tubular reactor before entering Fully react in the two-stage tubular reactor, the temperature is strictly controlled at -5~0°C during the reaction process, and the residence time of each stage is 280s. The outlet of the secondary tubular reactor was sampled by GC to detect that the reaction end point was 0....

Embodiment 2

[0030] (1) Add quantitative cyanuric chloride and 5 times the mass of toluene to the cyanuric chloride dissolving tank, stir and dissolve at -5~0°C to obtain a homogeneous solution for subsequent use;

[0031](2) Control the flow rate of cyanuric chloride solution at 18T / h, and the flow rate of isopropylamine (99.8% content) at 0.87T / h, and pump them into the first-stage double-group static mixer respectively, and enter the first-stage after mixing Fully react in the tubular reactor, then accurately pump the 5% sodium hydroxide aqueous solution into the second-stage double-group static mixer at a flow rate of 11.88T / h, mix with the output liquid from the first-stage tubular reactor, and then enter Fully react in the two-stage tubular reactor. During the reaction, the temperature is strictly controlled at 5-10°C, and the residence time of each stage is 80s. The outlet of the secondary tubular reactor was sampled by GC to detect that the reaction end point was cyanuric chloride ...

Embodiment 3

[0036] (1) Add quantitative cyanuric chloride and 15 times the mass of toluene to the cyanuric chloride dissolving tank, stir and dissolve at 0~5°C, and obtain a homogeneous solution for subsequent use;

[0037] (2) Control the flow rate of cyanuric chloride solution at 16T / h and the flow rate of isopropylamine (99.7% content) at 0.29T / h, and pump them into the first-stage three sets of static mixers respectively, and enter the first-stage after mixing Fully react in the tubular reactor, then accurately pump the 30% sodium hydroxide aqueous solution into the second-stage three-group static mixer at a flow rate of 0.66T / h, mix with the output liquid from the first-stage tubular reactor, and then enter Fully react in the two-stage tubular reactor. During the reaction, the temperature is strictly controlled at 15-20°C, and the residence time of each stage is 30s. The outlet of the secondary tubular reactor was sampled by GC to detect that the reaction end point was 0.016% cyanuri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com