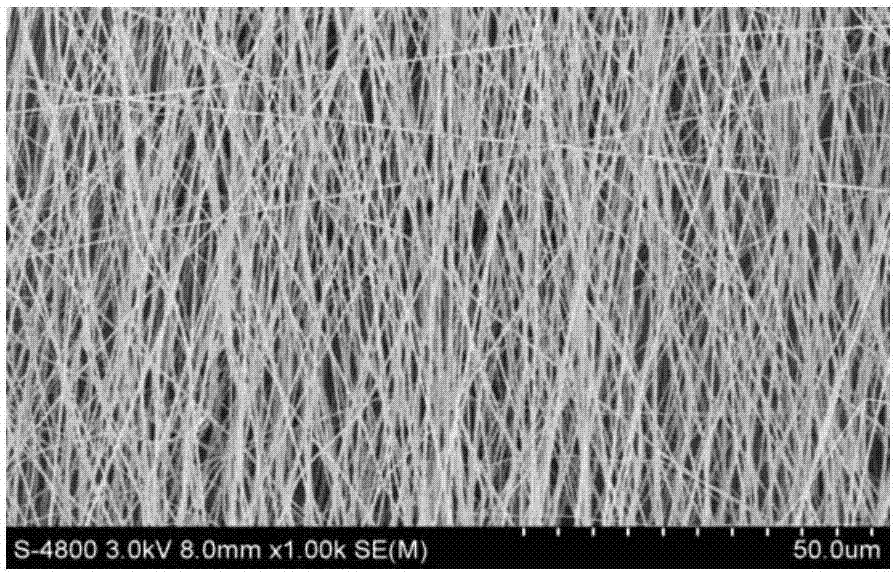

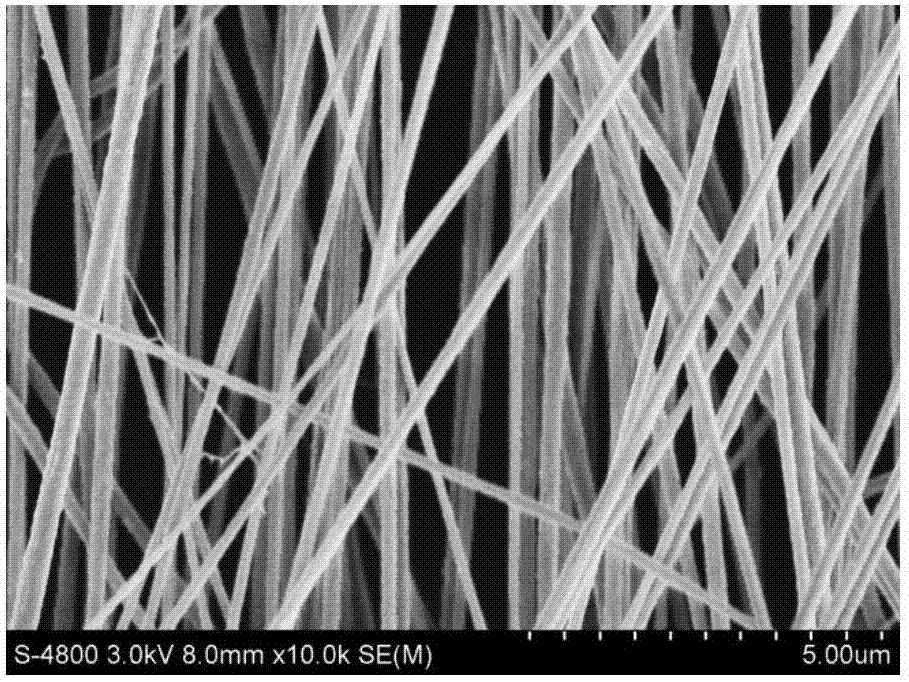

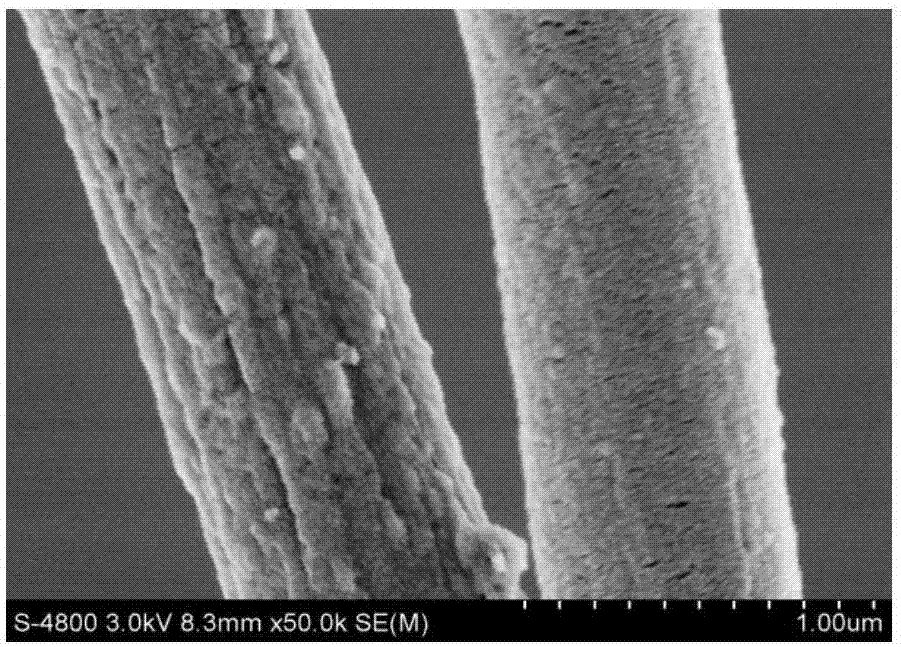

Preparing method for oriented-zinc-oxide-nanometer-bar-loaded fiber membrane

A technology of zinc oxide nanorods and fiber membranes, applied in fiber processing, fiber chemical characteristics, rayon manufacturing, etc., can solve the problems of limited application, limited performance of disordered fibers, and difficulty in improving, etc., to increase the application range, catalyze Improved degradation efficiency and high controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] (1) Preparation of ZnO seed layer

[0052] S1: Preparation of spinning solution

[0053] Weigh 5g of polyvinylidene fluoride (PVDF) particles and place them in a beaker, and add a mixed solvent of 31.5g N,N-dimethylformamide (DMF) and 23.5g of acetone to the beaker (the mass ratio of DMF to acetone is 7:3). Then place the beaker in a heat-collecting magnetic heating stirrer for heating and stirring in a water bath, and the temperature of the water bath is 55°C. After the PVDF particles are completely dissolved to form a uniform transparent solution, a PVDF solution with a concentration of 10% is obtained. At room temperature, add 1.5 g of anhydrous zinc acetate (Zn(Ac) 2 ) powder and placed on a magnetic stirrer to stir until a uniformly dispersed solution is formed to obtain PVDF / Zn(Ac) 2 mixed solution.

[0054] 0.5g of γ-Fe 2 o 3 The nanoparticles were dispersed into a mixed solvent of DMF (3.15g) and acetone (1.35g) (the mass ratio of DMF to acetone was 7:3),...

Embodiment 2

[0066] This implementation is used as a control experiment, and the specific method is as follows:

[0067] (1) Preparation of ZnO seed layer

[0068] S1: Preparation of spinning solution

[0069] Weigh 5g of polyvinylidene fluoride (PVDF) particles and place them in a beaker, and add a mixed solvent of 31.5g N,N-dimethylformamide (DMF) and 23.5g of acetone to the beaker (the mass ratio of DMF to acetone is 7:3). Then place the beaker in a heat-collecting magnetic heating stirrer for heating and stirring in a water bath, and the temperature of the water bath is 55°C. After the PVDF particles are completely dissolved to form a uniform transparent solution, a PVDF solution with a concentration of 10% is obtained. At room temperature, add 1.5 g of anhydrous zinc acetate (Zn(Ac) 2 ) powder and placed on a magnetic stirrer for stirring until a uniformly dispersed solution is formed to obtain a spinning solution.

[0070] S2: PVDF / Zn(Ac) 2 Preparation of nanofibers

[0071] E...

Embodiment 3

[0079] This implementation is used as a control experiment, and the specific method is as follows:

[0080] (1) Preparation of ZnO seed layer

[0081] S1: Preparation of spinning solution

[0082] Weigh 5g of polyvinylidene fluoride (PVDF) particles and place them in a beaker, and add a mixed solvent of 31.5g N,N-dimethylformamide (DMF) and 23.5g of acetone to the beaker (the mass ratio of DMF to acetone is 7:3). Then place the beaker in a heat-collecting magnetic heating stirrer for heating and stirring in a water bath, and the temperature of the water bath is 55°C. After the PVDF particles are completely dissolved to form a uniform transparent solution, a PVDF solution with a concentration of 10% is obtained.

[0083] S2: PVDF / Zn(Ac) 2 Preparation of nanofibers

[0084] Electrospinning was carried out on the spinning solution, wherein the spinning voltage was 15kV, and the spinning distance was 12cm. After electrospinning is completed, a PVDF nanofiber membrane is obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com