Preparation method of Li0.5TiO2 powder material

A powder material and powder technology, applied in the field of functional materials, can solve the problems of limited application and low electrical conductivity, and achieve the effects of high specific capacity, low preparation temperature, and easy industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] TiO 2 Powder and Li 2 CO 3 Weigh the corresponding masses according to the molar ratio of 1:1.05, and then fully grind and mix the two materials evenly. The mixed sample was placed in a corundum crucible, and kept at 650 ° C for 8 h in a tube furnace with high-purity argon to obtain Li 2 TiO 3 Powder material.

[0019] Will Li 2 TiO 3 Weigh two samples of corresponding mass according to the molar ratio of 2:1.05 with Mg, grind and mix thoroughly, put the fully mixed sample in a corundum crucible, and then put it into a tube furnace with high-purity argon gas at 600 ℃ insulation 6h for magnesia thermal reduction reaction. The product obtained after the reaction was put into dilute hydrochloric acid solution and stirred for 1 h, then the residue was repeatedly washed with alcohol and deionized water, centrifuged and dried to obtain Li 0.5 TiO 2 Powder material.

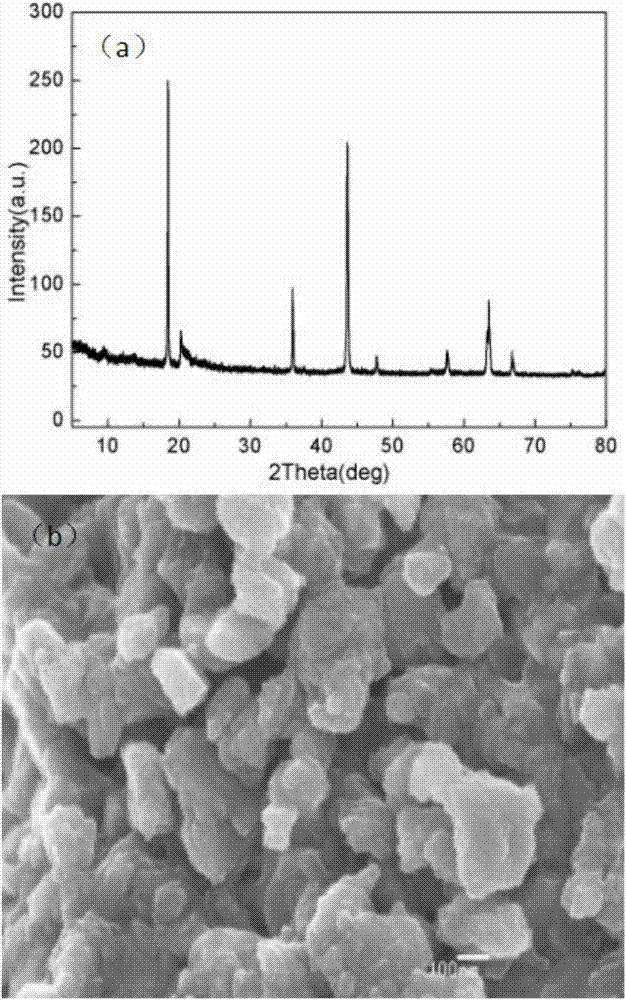

[0020] figure 1 (a) is Li 2 TiO 3 The X-ray diffraction spectrum of Li 2 TiO 3 The standard spe...

Embodiment 2

[0023] The prepared Li 2 TiO 3 Weigh the two samples of corresponding mass according to the molar ratio of 2:1.2 with Mg, grind and mix them thoroughly, put the fully mixed samples in a corundum crucible, and then put them into a tube furnace with high-purity argon gas at Incubate at 620°C for 4h for magnestic reduction reaction. The product obtained after the reaction was put into dilute hydrochloric acid solution and stirred for 1 h, then the residue was repeatedly washed with alcohol and deionized water, centrifuged and dried to obtain Li 0.5 TiO 2 Powder material.

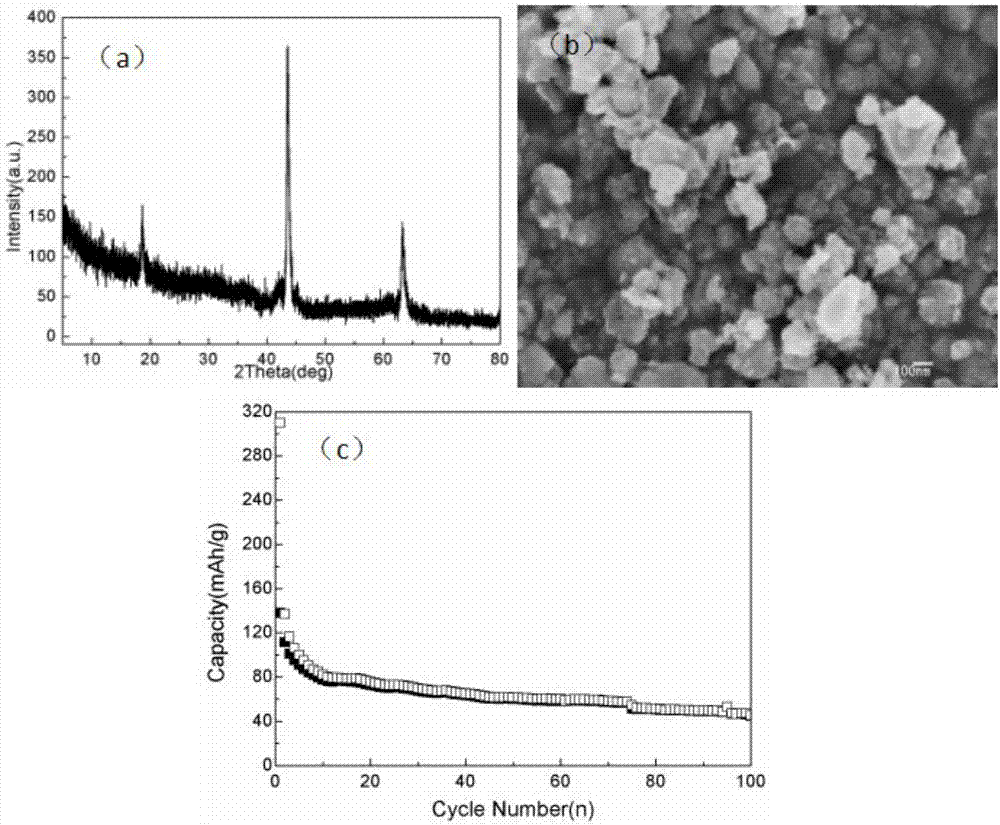

[0024] image 3 (a) is the X-ray diffraction spectrum of the magnesium thermal reduction product, and LiTiO 2 The standard map (PDF#40-1053) is consistent. Inductively coupled plasma atomic emission spectrometry analysis shows that the atomic ratio of Li:Ti in the product is 0.5:1, so the product is Li 0.5 TiO 2 . image 3 (b) is its SEM photo, Li 0.5 TiO 2 The particle size of the powder is about 10...

Embodiment 3

[0026] The prepared Li 2 TiO 3 Weigh the two samples of corresponding mass according to the molar ratio of 2:1.4 with Mg, grind and mix them thoroughly, put the fully mixed samples in a corundum crucible, and then put them into a tube furnace with high-purity argon gas at Incubate at 640°C for 3h for magnestic reduction reaction. The product obtained after the reaction was put into dilute hydrochloric acid solution and stirred for 1 h, then the residue was repeatedly washed with alcohol and deionized water, centrifuged and dried to obtain Li 0.5 TiO 2 Powder material.

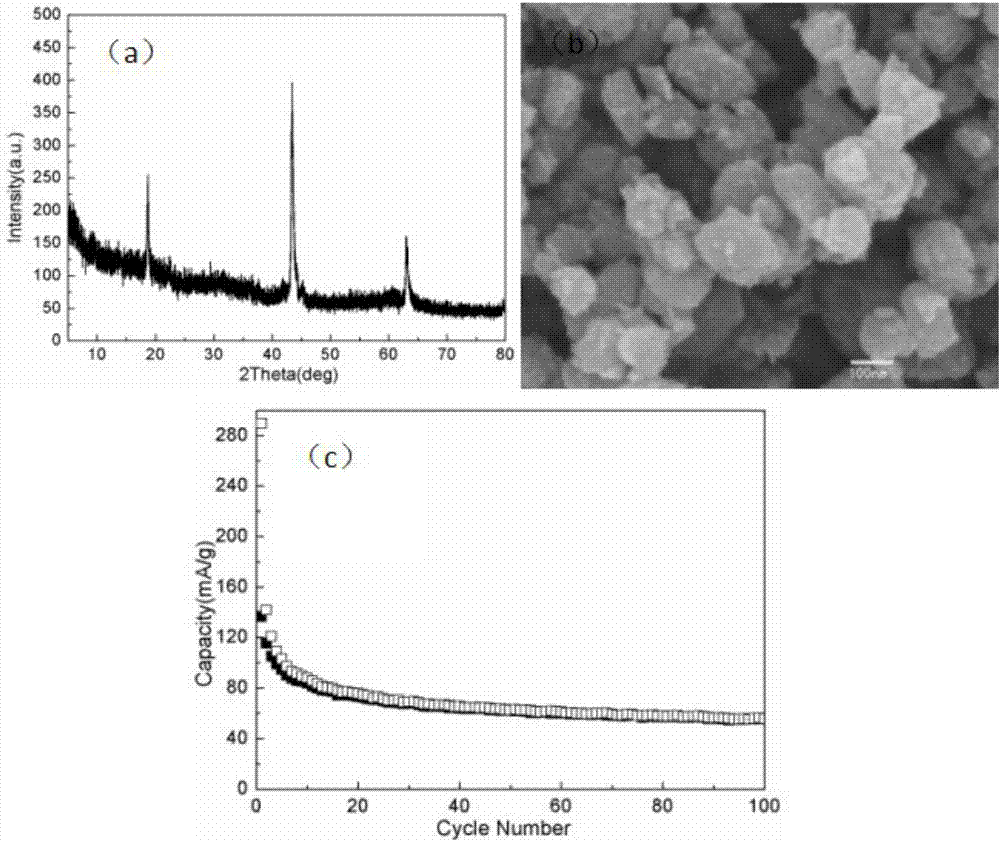

[0027] Figure 4 (a) is the X-ray diffraction spectrum of the magnesium thermal reduction product, and LiTiO 2 The standard map (PDF#40-1053) is consistent. Inductively coupled plasma atomic emission spectrometry analysis shows that the atomic ratio of Li:Ti in the product is 0.5:1, so the product is Li 0.5 TiO 2 . Figure 4 (b) is Li 0.5 TiO 2 Scanning electron microscope pictures of powder material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com