Cow dung fermentation method

A fermentation method and technology of cow dung, which is applied in the field of cow dung fermentation, can solve the problems of low decomposing degree, slow temperature rise, long fermentation period, etc., and achieve the effect of high decomposing degree, fast temperature rise and short fermentation period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

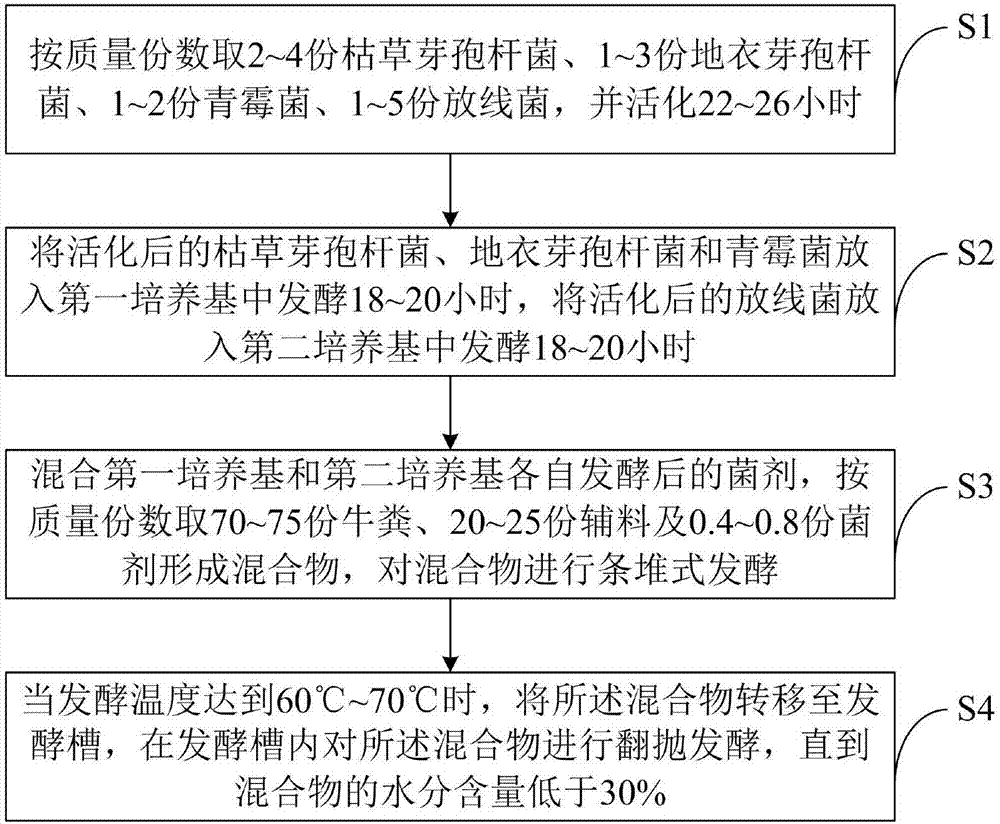

[0026] The cow dung fermentation method of the present embodiment comprises:

[0027] Step S1, take 2 parts of Bacillus subtilis, 2 parts of Bacillus licheniformis, 2 parts of Penicillium, and 5 parts of actinomycetes according to the number of parts by mass, and activate for 26 hours. In the subsequent step S2, the cultured bacterial solution is subjected to a combined orthogonal test to detect cellulase activity, and the ratio of mass parts of Bacillus subtilis, Bacillus licheniformis, Penicillium and actinomycetes measured in the test is 2 :2:2:5, the cellulase activity is the largest.

[0028] Step S2, put the activated Bacillus subtilis, Bacillus licheniformis and Penicillium into the first medium to ferment for 20 hours, put the activated actinomycetes into the second medium to ferment for 20 hours, the first Medium comprises by mass percentage: CMC-Na0.6%, (NH 4 ) 2 SO 4 0.3%, Peptone 0.4%, CaCl 2 0.03%, KH 2 PO 4 0.4%, the rest is water; the second culture mediu...

Embodiment 2

[0035] The cow dung fermentation method of the present embodiment comprises:

[0036]Step S1, take 2 parts of Bacillus subtilis, 2 parts of Bacillus licheniformis, 2 parts of Penicillium, and 5 parts of actinomycetes according to the number of parts by mass, and activate for 26 hours. In the subsequent step S2, the cultured bacterial solution is subjected to a combined orthogonal test to detect cellulase activity, and the ratio of mass parts of Bacillus subtilis, Bacillus licheniformis, Penicillium and actinomycetes measured in the test is 2 :2:2:5, the cellulase activity is the largest.

[0037] Step S2, putting the activated Bacillus subtilis, Bacillus licheniformis and Penicillium in the first culture medium to ferment for 18 hours, putting the activated actinomycetes in the second culture medium to ferment for 18 hours, the first Medium comprises by mass percentage: CMC-Na0.4%, (NH 4 ) 2 SO 4 0.2%, peptone 0.2%, CaCl 2 0.01%, KH 2 PO 4 0.2%, the rest is water; the s...

Embodiment 3

[0044] The cow dung fermentation method of the present embodiment comprises:

[0045] Step S1, take 2 parts of Bacillus subtilis, 2 parts of Bacillus licheniformis, 2 parts of Penicillium, and 5 parts of actinomycetes according to the number of parts by mass, and activate for 26 hours. In the subsequent step S2, the cultured bacterial solution is subjected to a combined orthogonal test to detect cellulase activity, and the ratio of mass parts of Bacillus subtilis, Bacillus licheniformis, Penicillium and actinomycetes measured in the test is 2 :2:2:5, the cellulase activity is the largest.

[0046] Step S2, put the activated Bacillus subtilis, Bacillus licheniformis and Penicillium into the first medium to ferment for 19 hours, put the activated actinomycetes into the second medium to ferment for 19 hours, the first Medium comprises by mass percentage: CMC-Na0.5%, (NH 4 ) 2 SO 4 0.25%, peptone 0.3%, CaCl 2 0.02%, KH 2 PO 4 0.3%, the rest is water; the second culture medi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com