A kind of polysaccharide improving the quality of high-moisture peanut drawing protein

A technology for drawing protein and peanut protein powder, which is applied in vegetable protein processing, food science and other directions, can solve the problems of unconsidered product color, fragrance, etc., and achieve the effects of rich fragrance, less addition, and good taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

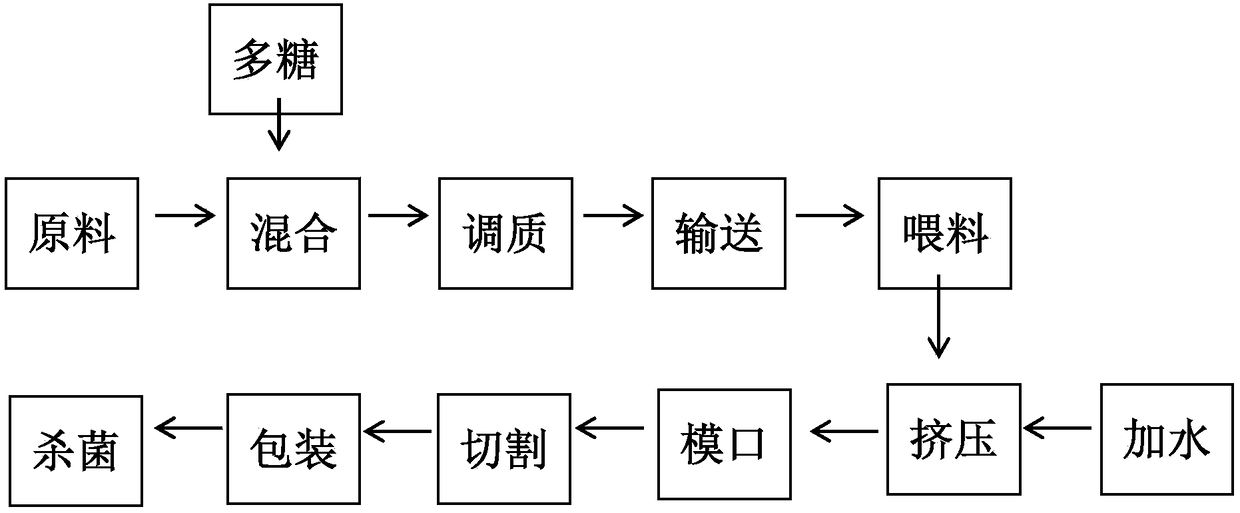

[0052] A method for polysaccharides to improve the quality of high-moisture peanut silk protein, comprising the steps of:

[0053] (1) Raw material crushing: crush the low-temperature defatted peanut protein powder into small particles, pass through a 60-80 mesh sieve, and weigh 5kg;

[0054] (2) Raw material premixing: mix crushed peanut protein powder and 0.2% sodium alginate in a mixer for 2-10 minutes, and balance for 20-24 hours;

[0055] (3) Screw element combination: high-shear combination, that is, the shear element selects a kneading block with a shear angle of 45°, puts the assembled screw into the extruder barrel, and fixes it firmly;

[0056] (4) Extruder preheating: preheat the twin-screw extruder after starting, so that the temperature in the feeding zone of the extruder barrel is 70°C, the temperature in the mixing zone is 95°C, and the temperature in the cooking zone is 149°C. °C, the temperature in the cooling zone is 120 °C, and the temperature in the formin...

Embodiment 2

[0064] A method for improving the quality of high-moisture peanut silk protein with polysaccharides, the specific operation steps are the same as those in Example 1, the only difference is that in step (2), 0.2% sodium alginate is replaced by 0.1% carrageenan.

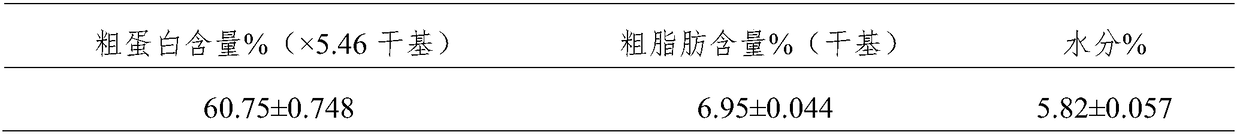

[0065] The detection results of the high-moisture peanut silk protein obtained in the present embodiment are as follows:

[0066]

Embodiment 3

[0068] A method for improving the quality of high-moisture peanut silk protein with polysaccharides, the specific operation steps are the same as in Example 1, the only difference is that in step (2), 0.2% sodium alginate is replaced by 4% wheat starch.

[0069] The detection results of the high-moisture peanut silk protein obtained in the present embodiment are as follows:

[0070]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com