A functionalized magnetic graphene oxide catalyst material containing hydroxylamine compounds and its preparation method and application

A technology of graphene catalytic materials and compounds, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, physical/chemical process catalysts, etc. Low material bonding, complex preparation process, easy to fall off and other problems, to achieve the effect of reducing loss and consumption, high catalytic activity, and avoiding falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The preparation method of graphene oxide is as follows:

[0040] (1) Measure 23mL of concentrated sulfuric acid (98%), pour it into a three-necked flask and then ice-bath it to lower its temperature below 4°C. Subsequently, 1 g of graphite powder and 0.5 g of sodium nitrate were weighed. After it is dispersed in concentrated sulfuric acid, slowly add 3g of potassium permanganate into the mixed solution within 1h, and control the reaction temperature during the addition process not to exceed 10°C; after the addition of potassium permanganate is completed, react below 10°C for 1h.

[0041] (2) The temperature of the mixed solution obtained from the above reaction was raised to 38° C., and allowed to react with stirring at 38° C. for 0.5 h. Subsequently, 80 mL of distilled water was slowly added to the mixed solution. And slowly raise the temperature to 95°C, and keep stirring for 30min. Afterwards, 60 mL of deionized water was added to the mixed solution to stop the re...

Embodiment 2

[0044] The preparation method of the magnetic graphene oxide catalytic material of triethanolamine functionalization is as follows:

[0045] (1) Add 10 g of 98% triethanolamine into 20 mL of distilled water, and stir at room temperature for 30 min.

[0046] (2) 0.3g FeCl 3 ·6H 2 O was added to the above solution and stirred at 25 °C for 30 min.

[0047] (3) Add 15 mL (concentration of about 6 mg / mL) graphene oxide suspension into the solution prepared in step (2), and stir at 25° C. for 30 min.

[0048] (4) Add the stirred reaction precursor into a polytetrafluoroethylene-lined reactor, set the heating rate of the reactor so that the temperature of the solution in the reactor rises to 200°C within 200 minutes, and Insulation reaction 6h.

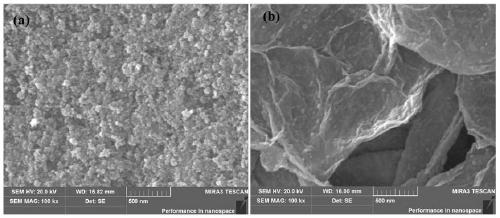

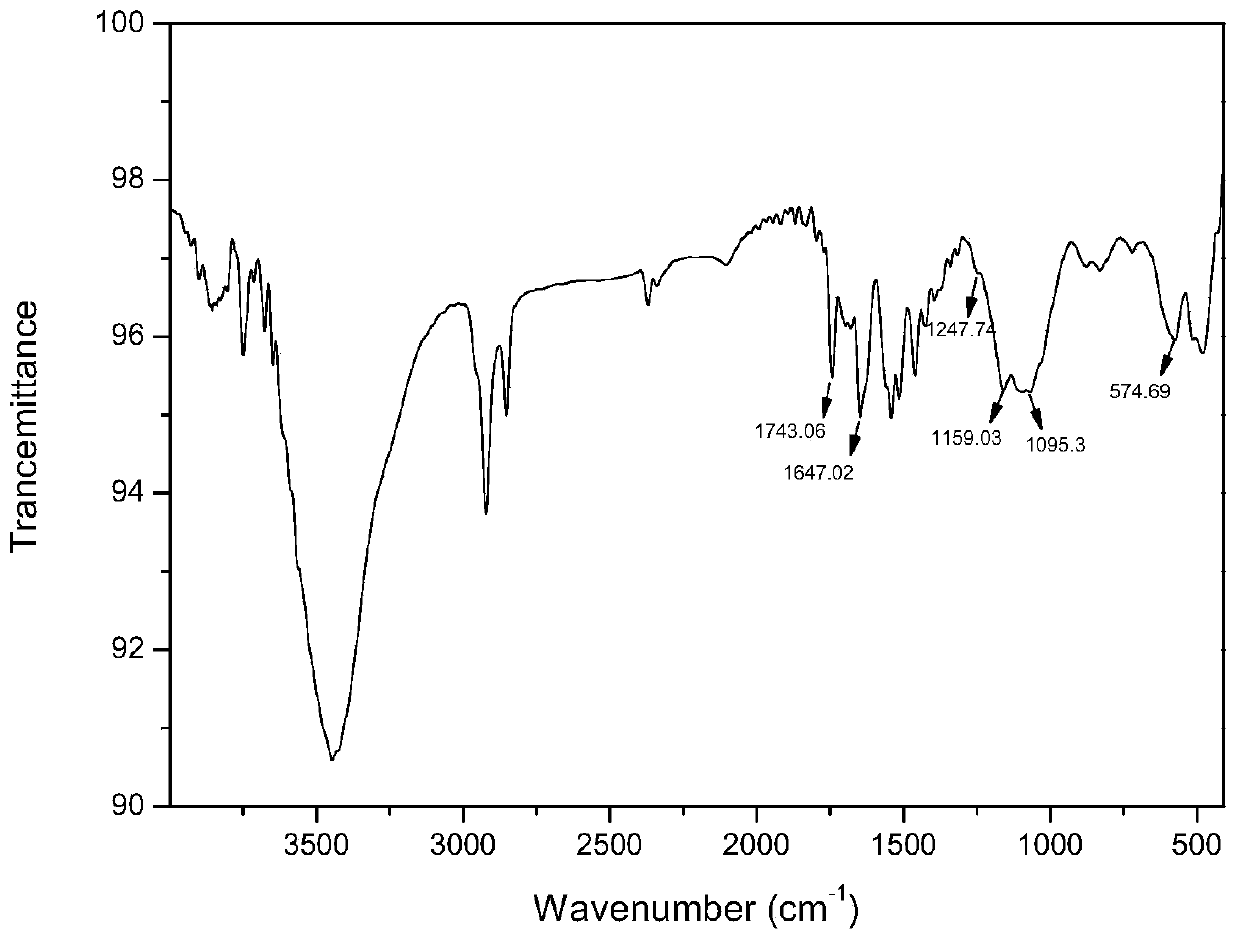

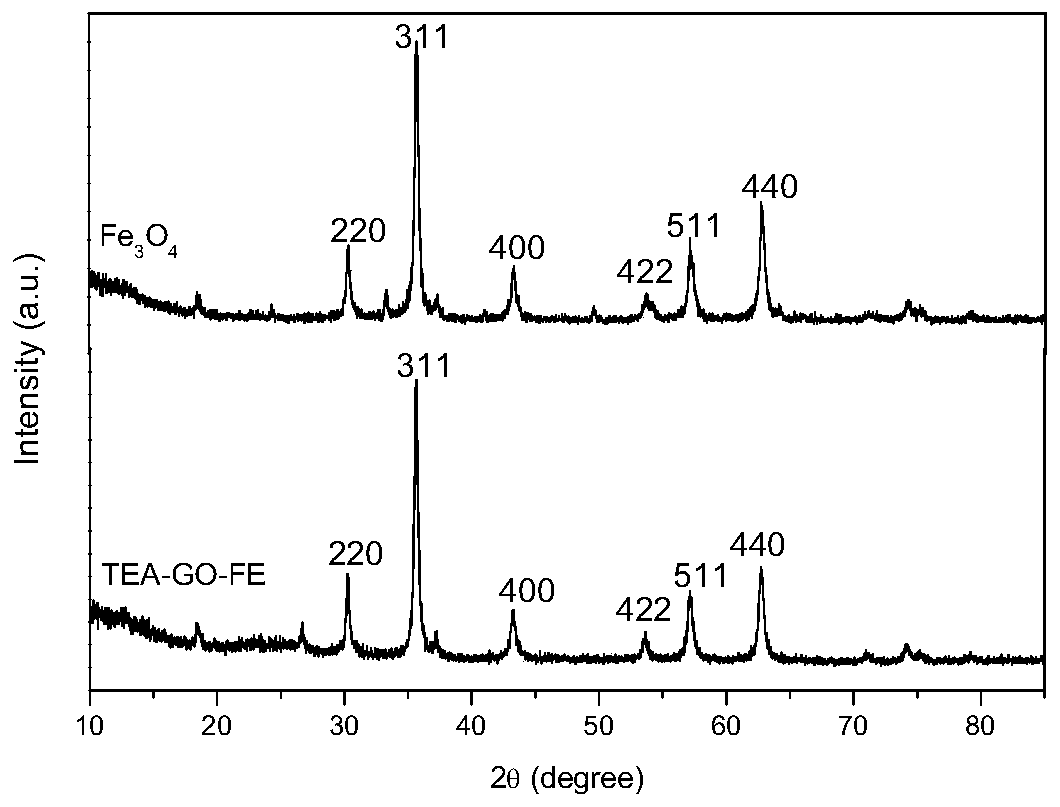

[0049] (5) After the reaction is completed, after the temperature of the reactor is cooled to room temperature, it is washed to neutrality with an aqueous solution, and the magnetic graphene oxide catalytic material (A) modified by triet...

Embodiment 3

[0054] Catalytic degradation performance of ferroferric oxide nanoparticles and triethanolamine functionalized magnetic graphene oxide catalytic material for methylene blue:

[0055] Preparation 50mL concentration is 100mg / L, and pH is the solution of the methylene blue of 4.0, wherein the concentration of hydrogen peroxide is 10mmol / L, adds the magnetic graphene oxide catalytic material of ferric oxide nano-particle and triethanolamine functionalization of 10mg respectively, React at 80°C for 35 minutes. The experimental results are as Figure 4 shown by Figure 4 It can be seen that the triethanolamine functionalized magnetic graphene oxide material (A) has a degradation rate of more than 98% for methylene blue in 5 minutes, and its degradation rate is much higher than that of ferric oxide nanoparticles. This shows that the triethanolamine-functionalized magnetic graphene oxide can effectively solve the problem of agglomeration of iron ferric oxide nanoparticles, and the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com