Structural metal fuse material additive device and fuse manufacturing technology thereof

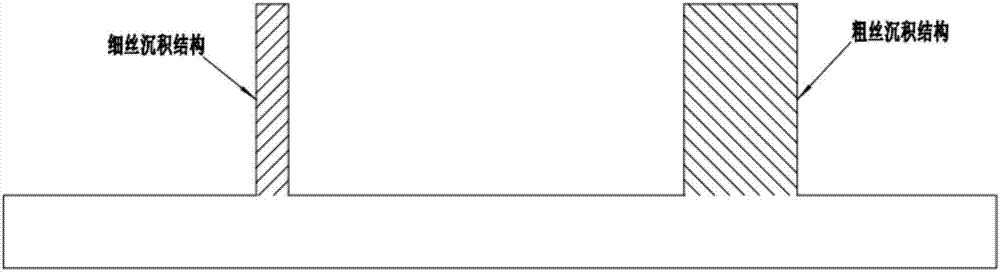

A technology for manufacturing metal structural parts and fuses, which is applied in the field of additive manufacturing, can solve the problems of increasing the amount of milling, and the small structure cannot be milled, so as to reduce the amount of cutting, take into account surface quality and deposition efficiency, and improve work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention is described in further detail below in conjunction with accompanying drawing:

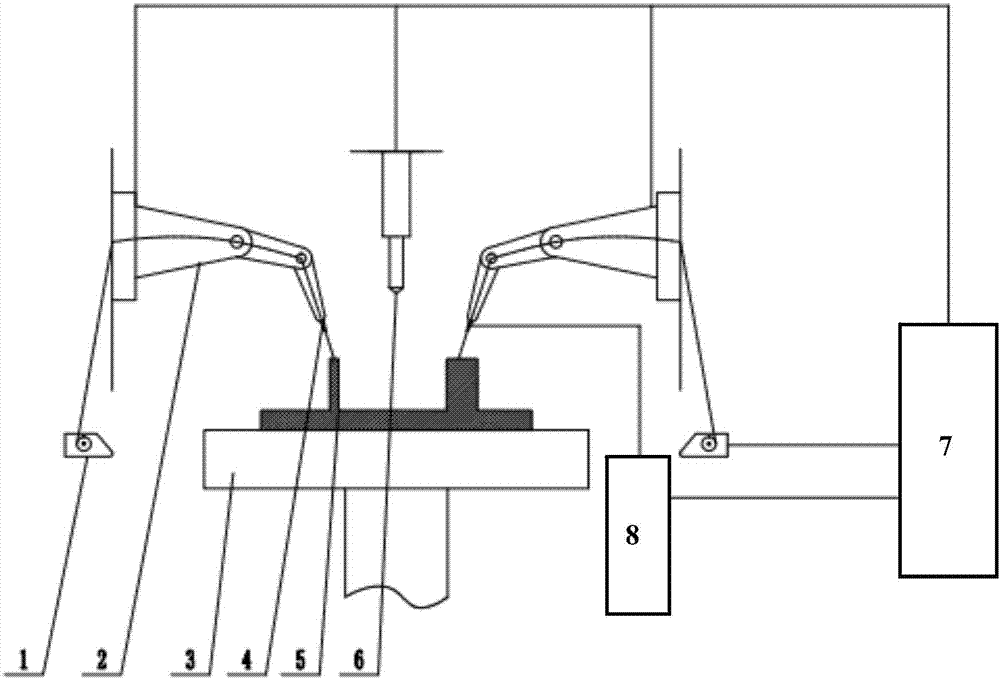

[0039] see figure 1 : The fuse wire additive device for metal structural parts of the present invention includes a wire feeding system 1, a plurality of robots 2, a working platform 3, a welding torch 4, a molded part 5, a numerical control milling system 6, a control system 7 and a welding machine host 8.

[0040] The working platform 3 of the present invention is used to carry the molded parts, with the plane of the working platform 3 as the horizontal plane, it can rotate in the horizontal direction and turn over in the vertical direction.

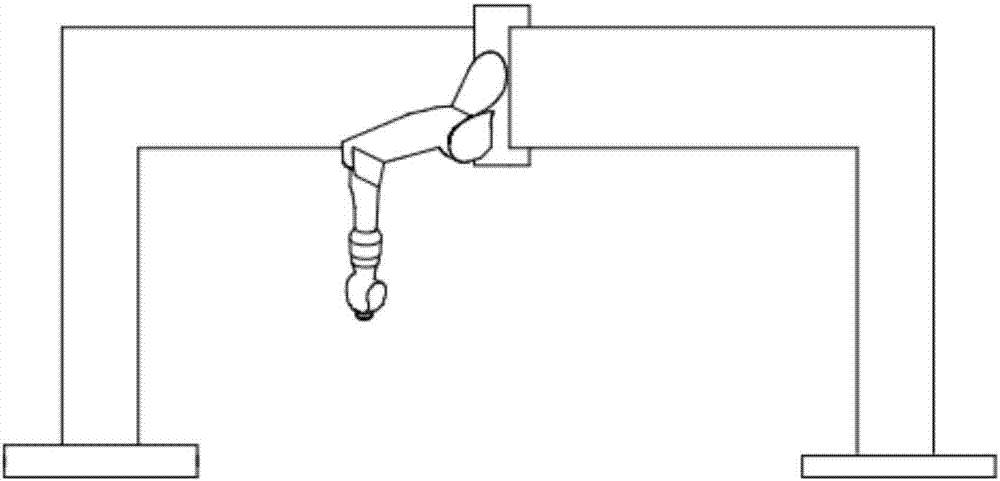

[0041] The robots 2 are symmetrically distributed on both sides of the working platform 3 and each robot 2 is individually fixed on the I-beam truss. In the preferred embodiment of the present invention, the robot 2 is a six-axis robot, and the robot 2 is symmetrically distributed on both sides of the work platform 3 and each r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com