Bacillus subtilis and application thereof

A technology of Bacillus subtilis and Lactobacillus plantarum, applied in application, bacteria, fungi and other directions, can solve problems such as waste and pollution of resources, and achieve the effects of improving fertility, reducing pests and diseases, and shortening fermentation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The invention provides a preparation method of a composite microorganism decomposing inoculum, the method comprising:

[0029] (1) Bacillus subtilis is Bacillus subtilis zzl-002 whose preservation number is CGMCC No.13758, and its fermentation method is 10% glucose, 10% soybean meal cake, 10% corn flour, 6% calcium carbonate, 7% sodium chloride , and the rest is water. The culture temperature was 37°C, and the rotation speed was 210rpm. After fermentation, it is dried into powder by spray drying method.

[0030] (2) The spore content of each microorganism in the composite microbial decomposing inoculum is: ≥100 billion / gram of Bacillus subtilis; ≥20 billion / gram of Lactobacillus plantarum; ≥10 billion / gram of Trichoderma viride; ≥10 billion / gram g of Aspergillus niger; ≥ 20 billion / g of Saccharomyces cerevisiae.

[0031] (3) The four bacterial agents are Lactobacillus plantarum powder ≥ 20 billion / g; Trichoderma viride powder ≥ 10 billion / g; Aspergillus niger powder ...

Embodiment 1

[0035] Preparation of microbial decomposing inoculum

[0036] Bacillus subtilis is Bacillus subtilis zzl-002 with a preservation number of 13758, and its fermentation method is 10% glucose, 10% soybean meal cake, 10% corn flour, 6% calcium carbonate, 7% sodium chloride, and the rest is water. The culture temperature was 37°C, and the rotation speed was 210rpm.

[0037] Fermentation was stopped when the spore content was greater than or equal to 100 billion / g.

[0038] After fermentation, it is dried into powder by spray drying method.

[0039] A fungus powder with a spore content of ≥100 billion / g is obtained.

[0040] In this example, Lactobacillus plantarum ≥ 20 billion / g; Trichoderma viride ≥ 10 billion / g; Aspergillus niger ≥ 10 billion / g; Saccharomyces cerevisiae ≥ 20 billion / g Provided by Technology Co., Ltd.

[0041] The five kinds of powder microbial inoculants are mixed evenly by weight ratio of 40% of Bacillus subtilis, 20% of Lactobacillus plantarum, 10% of Trich...

Embodiment 2

[0043] Use the compound inoculum in Example 1 to decompose the straw.

[0044] In Changle, Weifang, Shandong, July.

[0045] The straw and chicken manure are mixed in a ratio of 20:1, and the mixture is one ton. One kilogram of inoculum in Example 1 was mixed with one ton of the above-mentioned mixture. as experiment 1.

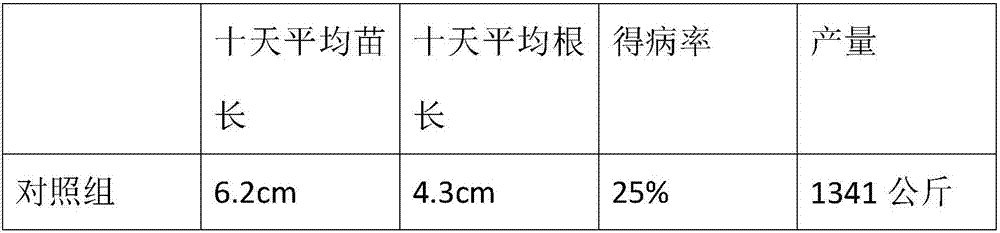

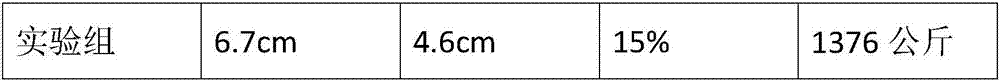

[0046] The straw and chicken manure are mixed in a ratio of 20:1, and the mixture is one ton. Do not mix with inoculants. as comparison.

[0047] The two kinds of mixed materials are piled into cones with a height of about 1.5 meters and a bottom diameter of about 5 meters.

[0048] The temperature of the experimental group was earlier and faster than that of the control group, and the fermentation time was shortened by 34%.

[0049]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com