Method for comprehensively recycling abandoned diamond tool valuable element through capacitance

A technology of diamond tools and valuable elements, which is applied in the direction of diamond, process efficiency improvement, electrodes, etc., can solve the problems of complex production process, increased production cost, slow recovery process, etc., achieve high output value and realize recycling , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

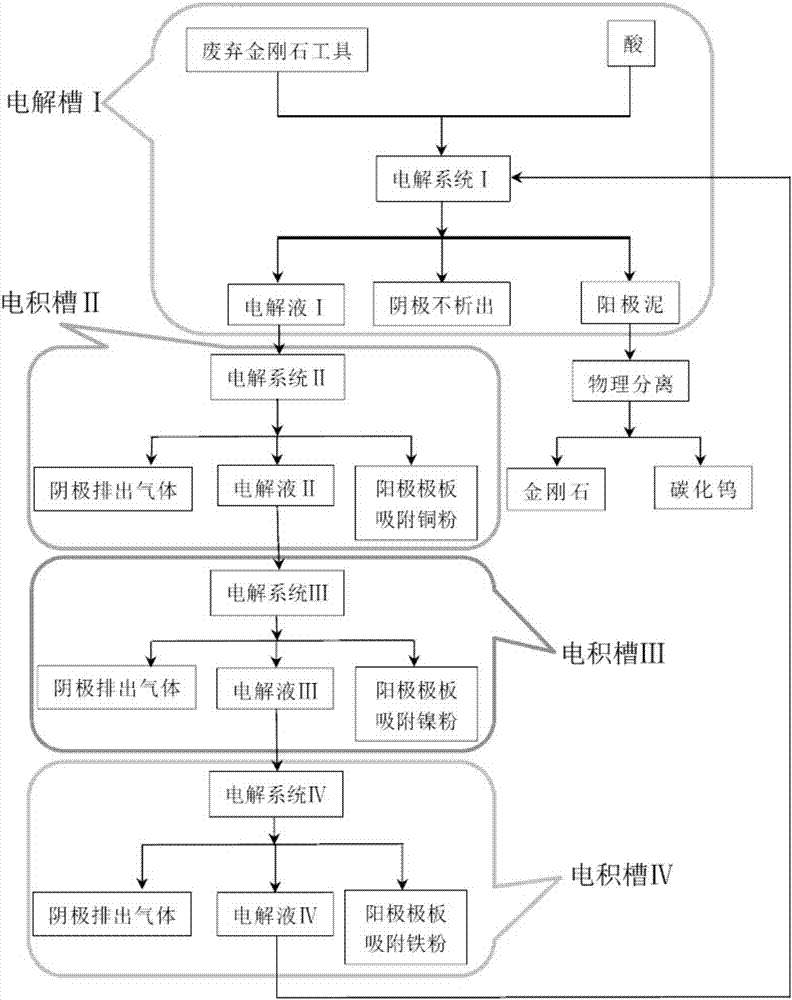

[0028] As shown in the figure, a method for comprehensively recycling valuable elements of discarded diamond tools through capacitance, the steps are as follows:

[0029] (1) Put the discarded diamond tools containing copper-nickel-iron into the electrolytic basket with isolation film, put the anode plate into the electrolytic basket, then put multiple electrolytic baskets into the electrolytic cell Ⅰ, and put the cathode in the electrolytic cell Ⅰ Inside, waste diamond and tungsten carbide are separated from other metal elements through the action of electric ions, wherein diamond and tungsten carbide powder form anode slime and are left in the electrolytic basket by the separator, and other metal ions enter the electrolyte Ⅰ through the separator , to control the concentration of electrolyte Ⅰ so that there will be no precipitates at the cathode;

[0030] (2) Wash the anode slime in step (1) with deionized water to remove metal ions and acid radical ions adsorbed on its surf...

Embodiment 2

[0036] As shown in the figure, a method for comprehensively recycling valuable elements of discarded diamond tools through capacitance, the steps are as follows:

[0037] (1) Put the discarded diamond tools containing copper, nickel, iron and cobalt into the electrolytic basket with isolation film, put the anode plate into the electrolytic basket, then put multiple electrolytic baskets into the electrolytic cell Ⅰ, and put the cathode in the electrolytic cell In Ⅰ, the waste diamond and tungsten carbide are separated from other metal elements through the action of electric ions, wherein the diamond and tungsten carbide powder form anode slime and are left in the electrolytic basket by the isolation film, and other metal ions enter the electrolyte Ⅰ through the isolation film Inside, control the concentration of electrolyte I so that there will be no precipitates at the cathode;

[0038] (2) Wash the anode slime in step (1) with deionized water to remove metal ions and acid rad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com