Method for preparing titanium dioxide special for cosmetics

A technology of titanium dioxide and cosmetics, which is applied in the field of titanium dioxide for cosmetics and its preparation, which can solve the problems of insufficient surface modification effect of titanium dioxide and affect the safety of titanium dioxide, and achieve the effect of strong lipophilicity, significant effect and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

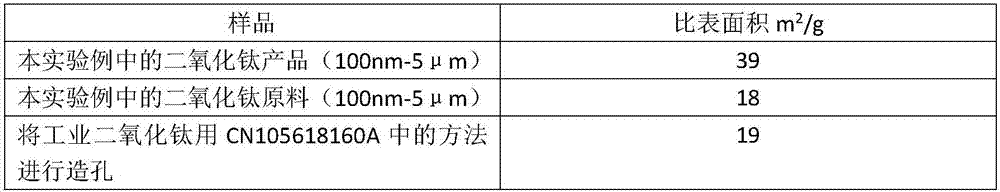

[0048] Microwaves are used to make holes in the particles to increase the specific surface area of the particles. This method is simple, quick and easy to control. When specifically related to titanium dioxide pore formation, those skilled in the art can only perform microwave pore formation on amorphous titanium dioxide, and porous amorphous titanium dioxide cannot be used as an additive in cosmetics and other applications, which in turn causes inconvenience in the use of this method.

[0049] Firstly, the method of CN105618160A is used to try to make pores on industrial titanium dioxide. (1) Weigh the raw materials according to the ratio of guanidine hydrochloride and amorphous titanium dioxide required for mixing C and N, and then mix and ball mill them for 5 minutes; The molar ratio of activated carbon is: 3:1.5:5); (3) Put the raw materials mixed in step (2) in a porcelain container, cover with a porcelain lid, and put it into a microwave oven. The mass" ratio is in th...

experiment example 2

[0057] In the experimental process of the present invention, the inventor found that in the step of destroying the hydrophilic bond, two reagents, ammonium acetate and peracetic acid, were selected to destroy the hydrophilic bond, and after the water content of titanium dioxide was controlled to 0.1-0.5%, the Microwave treatment can make titanium dioxide products have a larger specific surface area.

[0058] The specific experimental steps are as follows: Weigh industrial titanium dioxide, and sieve its particles to 100nm-5μm. Weigh 2kg of titanium dioxide, put it in 1kg of deionized water, add 100g of acetic acid to mix evenly, and adjust the pH to 3, then add 10g of reaction reagents respectively, wait for a period of time after the reaction, then add 50kg of deionized water, Suction filtration and drying were then performed. The water content of titanium dioxide is controlled at 0.2%.

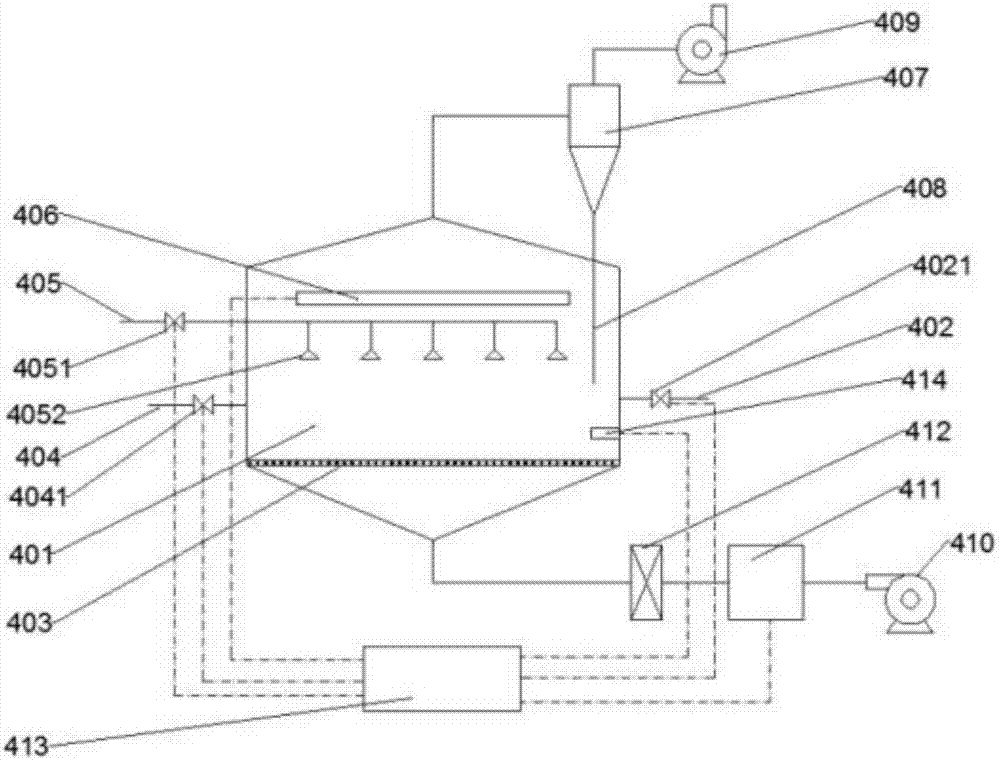

[0059] Take 1 kg of the above-mentioned titanium dioxide particles, pass them into and...

Embodiment 1

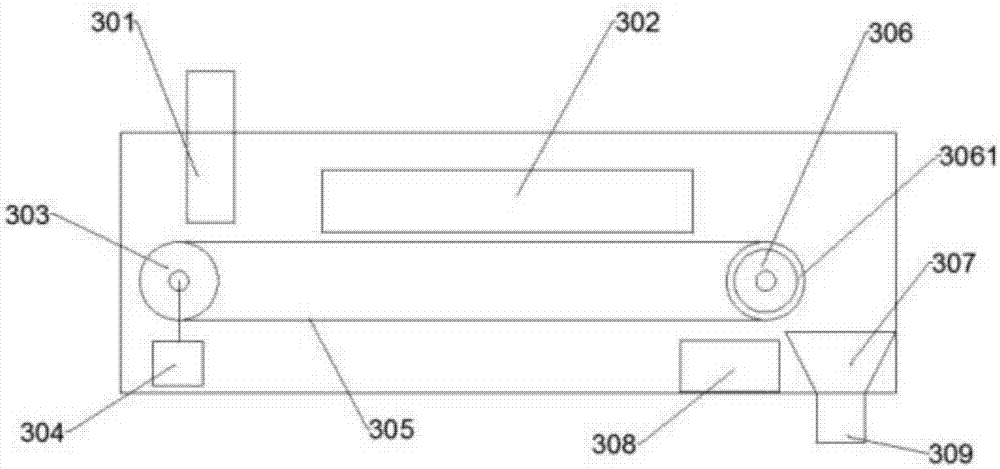

[0075] (1) Screen industrial titanium dioxide particles to 50nm-10μm. (2) Put the titanium dioxide particles and deionized water obtained in step (1) into the beating tank of the impurity removal device, the mixing ratio by weight between the titanium dioxide raw material and deionized water is 2:8; Form a slurry, inject the slurry into the first ultrasonic vibrating sieve for ultrasonic vibration filtration, and extract titanium dioxide by filtration; add ammonia water to the extracted titanium dioxide, adjust the pH of the solution to 1.0, and continuously add two Sodium methyldithiocarbamate solution until no solid suspended matter is produced, continue to stir for 15 minutes, and filter to extract titanium dioxide; after the titanium dioxide is filtered and extracted, it is washed with water, after washing, it is filtered by ultrasonic vibration, and then dried in a drying device. Titanium dioxide with a low impurity content is obtained. (3) Weigh 200g of titanium dioxide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com