Macromolecular biochar sphere-immobilized microalgal composite adsorbent and preparation and application thereof

A composite adsorption and high molecular polymer technology, which is applied in the direction of adsorption of water/sewage treatment, water pollutants, and other chemical processes, can solve the problems of nitrogen content, improve tolerance, facilitate recycling, and reduce costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] 1) The preparation of polymer biochar balls is to use one or more of agricultural and forestry wastes such as chaff, sawdust, straw, water hyacinth, and fruit shells as raw materials, first crushed, dried, and then cracked by microwave (power 1100 -1500W) to prepare biochar powder. The obtained biochar powder was dried in an oven at 105°C for 24 hours; β-cyclodextrin, sodium borohydride and water were added to a short-necked flat-bottomed flask, wherein the mass ratio of β-cyclodextrin to water was 1:1, The mass ratio of β-cyclodextrin to sodium borohydride ranges from 860:1 to 430:1, and stir until the cyclodextrin becomes a slurry. Weigh a certain amount of epichlorohydrin (the mass ratio of β-cyclodextrin to epichlorohydrin ranges from 1:1 to 1:1.5), and slowly drop it into the stirring liquid. After all the epichlorohydrin is dropped in, continue to stir for 15-25 minutes, and then slowly drop NaOH with a concentration of 40wt% (the mass ratio of β-cyclodextrin to ...

Embodiment 1

[0048] (1) Grind and grind the dried water hyacinth stems and leaves, and then crack them with 1300W microwave for 180s. The obtained biochar powder is mixed with β-cyclodextrin, sodium borohydride, water, epichlorohydrin, and NaOH with a concentration of 40wt%. After mixing with paraffin and going through a series of treatments such as mechanical stirring, the excess paraffin is filtered off, the polymer biochar spheres are washed with water or ethanol, and dried in an oven at 65°C to obtain the required polymer biochar spheres for use.

[0049] (2) Chlorella is selected as the algae species Chlorella vugaris , culture light intensity is 120 µmol photons / m 2 / s, the temperature is 26±2°C, the pH is 7, and the biomass concentration in the stock solution measured after 6 days of cultivation is 0.8g / L

[0050] (3) Put 2g of polymer biochar spheres into 50ml of algae liquid and let it stand for 5 hours to prepare the composite adsorbent for immobilizing microalgae with polymer ...

Embodiment 2

[0057] (1) Grind and grind the dried water hyacinth stems and leaves, and then crack them with 1300W microwave for 200s. After mixing with paraffin and going through a series of treatments such as mechanical stirring, the excess paraffin is filtered off, the polymer biochar spheres are washed with water or ethanol, and dried in an oven at 65°C to obtain the required polymer biochar spheres for use.

[0058] (2) Chlorella is selected as the algae species Chlorella vugaris , culture light intensity is 120 µmol photons / m 2 / s, the temperature is 26±2°C, the pH is 7, and the biomass concentration in the stock solution measured after 8 days of cultivation is 0.9g / L

[0059] (3) Put 2g of polymer biochar spheres into 50ml of algae liquid and let it stand for 5 hours to prepare the composite adsorbent for immobilizing microalgae with polymer biochar spheres. Another 2g of polymer biochar spheres was weighed for separate adsorption.

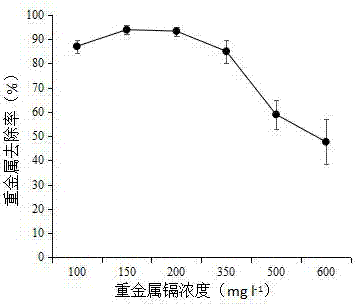

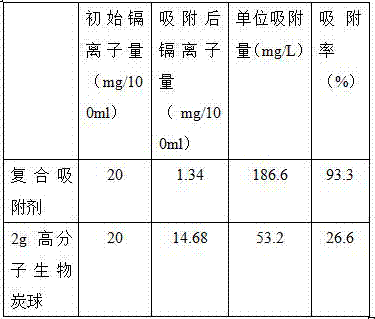

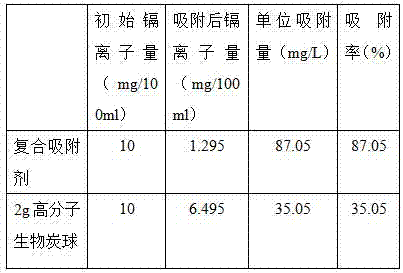

[0060] (4) The composite adsorbent and 2g of po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com