Steel/aluminum soldering method for nickel-zinc-plated composite coating

A composite coating, aluminum brazing technology, applied in welding equipment, manufacturing tools, metal processing equipment, etc., can solve the problem of insufficient spreading of brittle intermetallic compound brazing material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

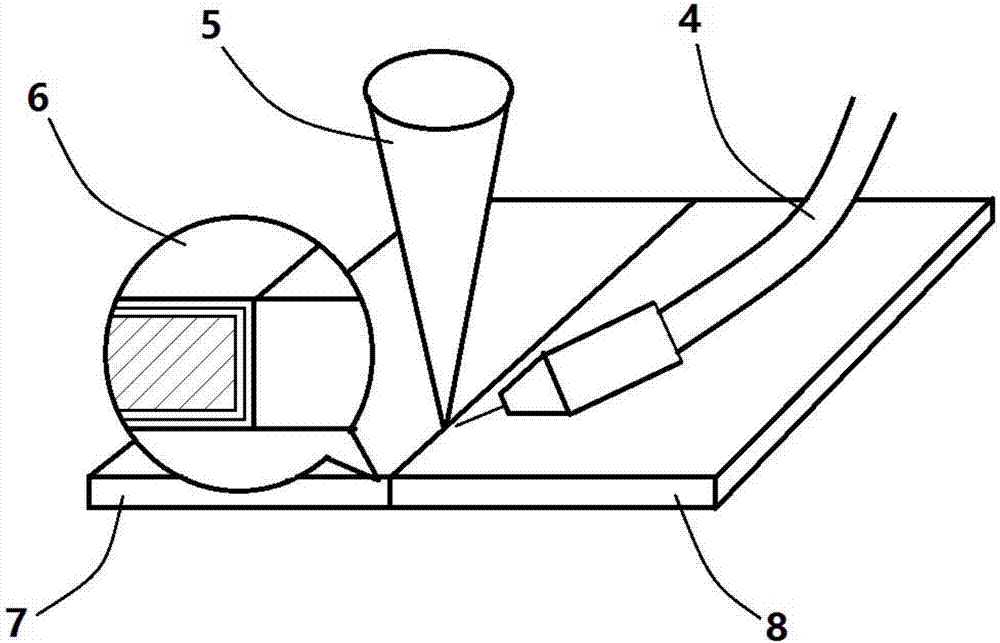

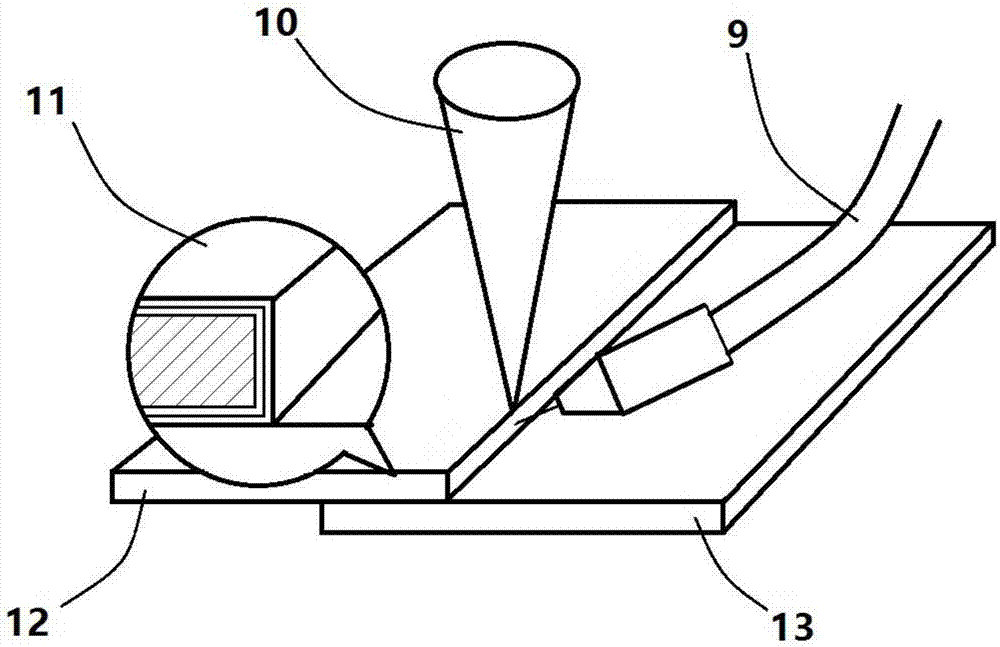

[0020] The embodiment provides a method for effectively connecting aluminum alloy plates and steel plates to Q235 steel plates and 5052 aluminum alloys using a laser-CMT hybrid welding method. The joint form is butt joint, wherein the base metal treatment method before welding and the welding process include The following steps:

[0021] A. Grind the steel plate and aluminum plate smoothly, and use acetone to degrease;

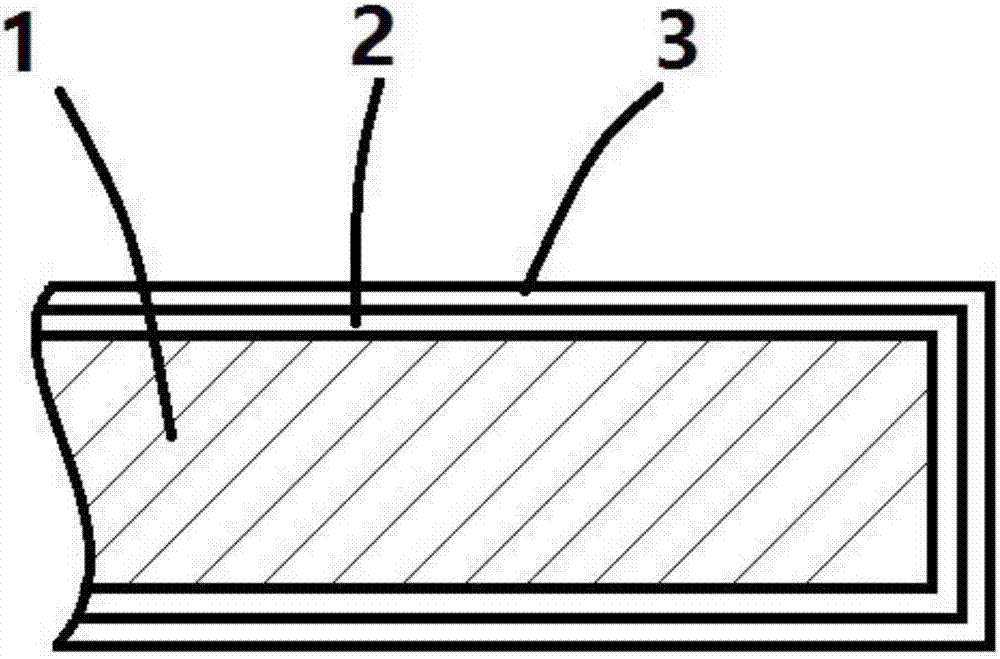

[0022] B. Immerse the cleaned steel plate in the nickel-containing electrolyte after pickling and activation to prepare a nickel layer with a thickness of 0.1 μm to 300 μm;

[0023] C. Rinse the nickel-plated steel plate, then intrude into the zinc-containing electrolyte, and prepare a galvanized layer with a thickness of 0.1 μm to 300 μm on the nickel-plated steel plate;

[0024] D. Clamp the processed steel plate and aluminum plate on the workbench in the form of docking, there is no gap between the two plates, and the laser light plate and welding torch ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com