High-performance barrier film and method for preparing same

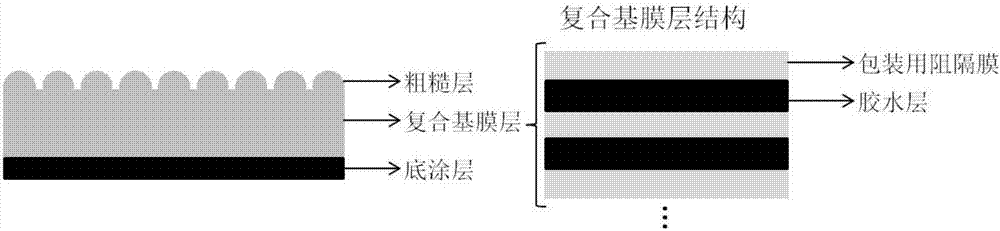

A barrier film and high-performance technology, applied in the field of preparation of high-performance barrier films, can solve the problems of high production cost, high selling price and high cost, and achieve the effects of reducing thickness and production cost, simple process method and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

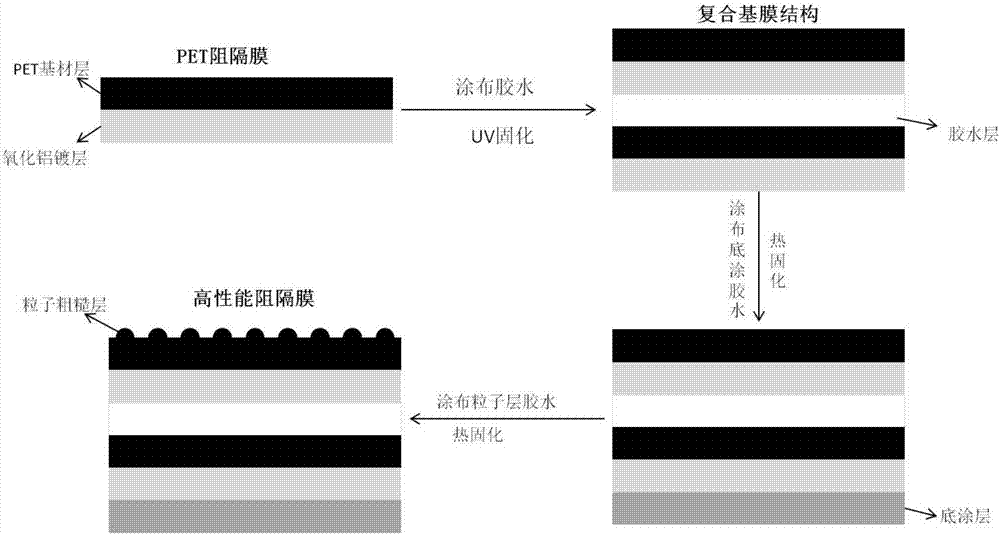

Embodiment 1

[0034] Japan's Mitsubishi PET barrier film for packaging is used, with a thickness of 12 μm and a water vapor transmission rate of 0.08g / m 2 ·day, light transmittance 95%, divided into two layers, PET substrate layer and aluminum oxide coating layer.

[0035] The preparation flow chart of this embodiment is as follows figure 2 As shown, its specific implementation steps are as follows:

[0036] Lay the aluminum oxide-coated side of the PET barrier film on the glass substrate facing up, fix the four corners and the middle of the four sides with glue strips, and use a No. 2 wire bar to coat a layer of methacrylic resin UV-curable glue with a solid content of 100%. And attach another PET barrier film with the aluminum oxide coating facing up, and then use 800mJ / cm 2 UV energy is used for curing to obtain a composite base film layer with a thickness of 27 μm.

[0037] On the aluminum oxide coating surface of the composite base film, use a No. 3 wire rod to scrape and coat poly...

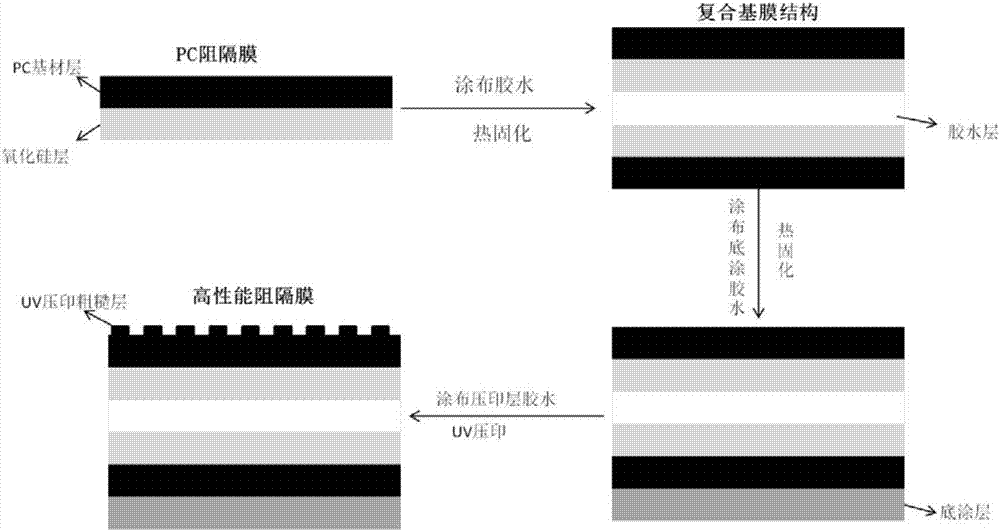

Embodiment 2

[0041] Adopt Japan Toray PC barrier film for packaging, its thickness is 30μm, water vapor transmission rate is 0.06g / m 2 .day, the light transmittance is 92%, and it is divided into two layers, which are PC substrate layer and silicon oxide layer.

[0042] The preparation flow chart of this embodiment is as follows image 3 As shown, its specific implementation steps are as follows:

[0043] Lay the silicon oxide layer of the PC barrier film upwards on the glass substrate, fix the four corners and the middle of the four sides with glue strips, use a No. After using an organic solvent, attach another PC barrier film with the PC base layer facing up, and dry it at 60°C to obtain a composite base film layer with a thickness of 66 μm.

[0044] On one side of the composite base film, a No. 2 wire rod was used to scrape polyacrylic acid heat-curable glue with a mass solid content of 50%, and cured and dried in a blast drying oven at 60°C to obtain a primer layer with a thickness ...

Embodiment 3

[0048] The Japanese Mitsubishi EVOH barrier film used for packaging has a thickness of 45μm and a water vapor transmission rate of 0.05g / m 2 .day, light transmittance 91%.

[0049]The preparation flow chart of this embodiment is as follows Figure 4 As shown, its specific implementation steps are as follows:

[0050] Spread the EVOH barrier film on the glass substrate, fix the four corners and the middle of the four sides with adhesive strips, use a No. 3 wire bar to coat a layer of methacrylic resin UV curing glue with a mass solid content of 80%, and attach another sheet EVOH barrier film, and then use No. 3 wire rod to coat a layer of methacrylic resin UV curing glue with a mass solid content of 100%, and then attach the third EVOH barrier film, and then use 1000mJ / cm 2 The UV energy is used for curing to obtain a composite base film layer with a thickness of 145 μm.

[0051] On one side of the composite base film, use a No. 10 wire rod to scrape and coat polyurethane he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com