Method for preparing tetrafluoroethane by virtue of trichloroethylene

A technology for trichloroethylene and tetrafluoroethane, which is applied in the field of preparing tetrafluoroethane from trichloroethylene, can solve the problems of low total yield of HFC-134a, strong corrosiveness of the reaction medium, inapplicability, etc., so as to reduce the reaction heat effect. , the effect of delaying the carbonization rate and improving the selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

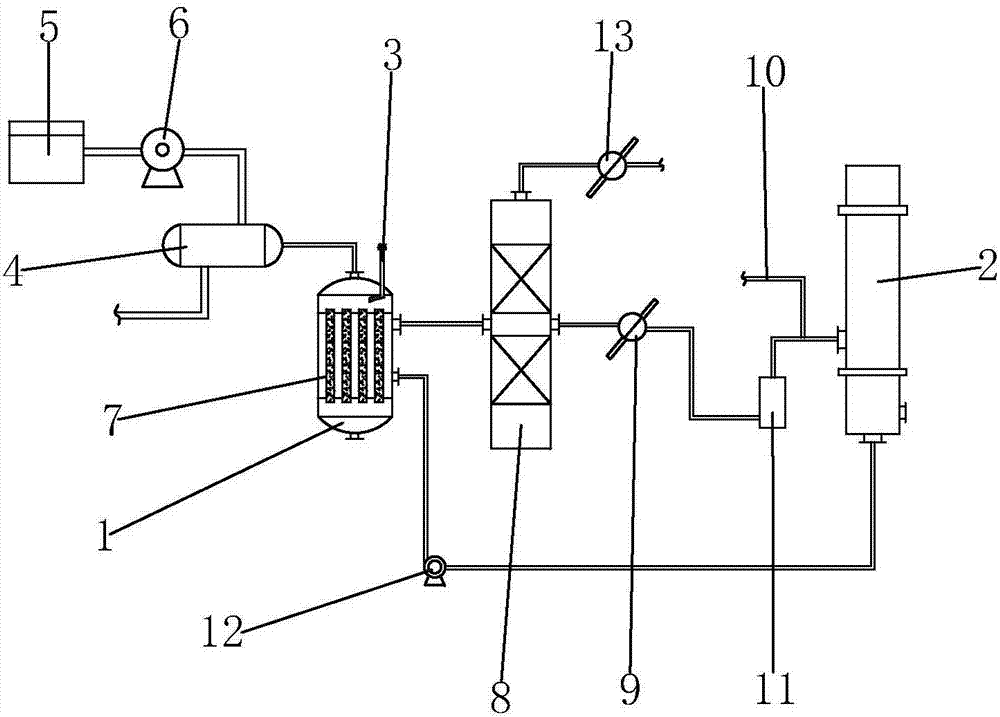

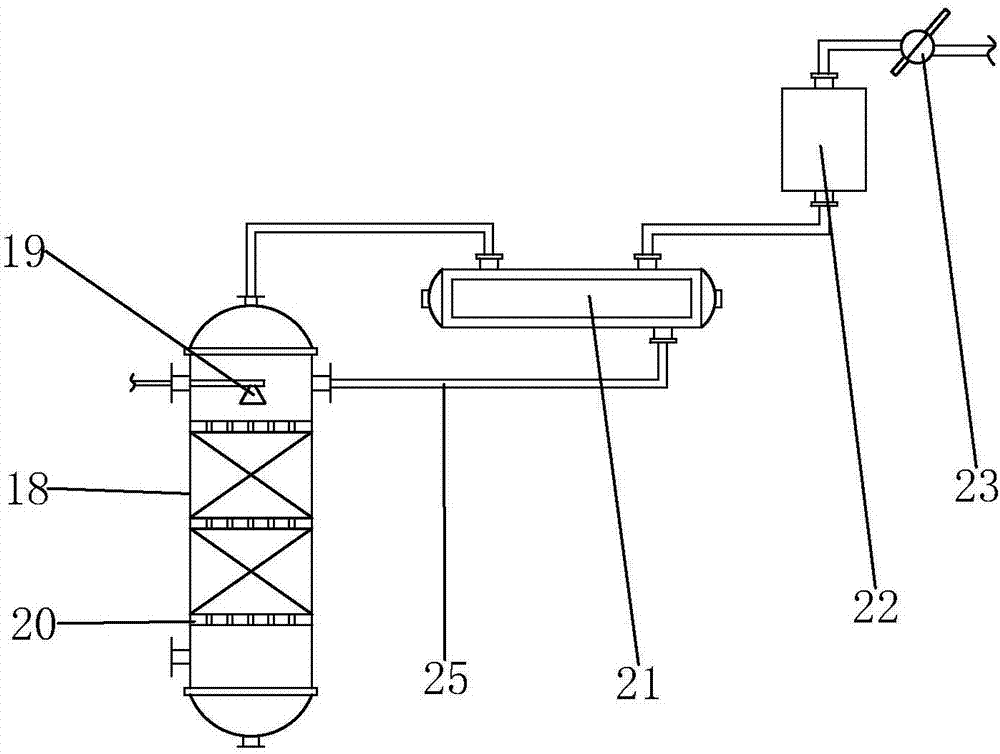

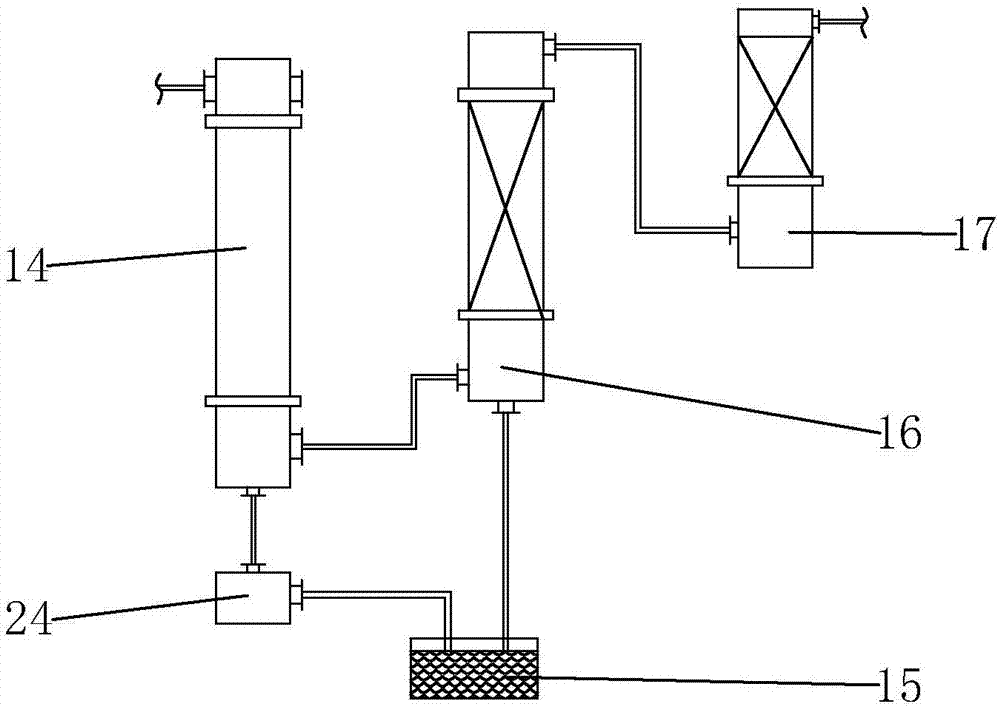

[0028] Such as Figure 1 to Figure 3 Shown, for a kind of trichlorethylene of the present invention prepares the method for tetrafluoroethane, comprises the steps:

[0029](a) Mixing preheating: Pre-activation is carried out by passing a mixed gas of hydrogen fluoride and nitrogen into the first reactor 1 and the second reactor 2 equipped with alumina, the activation temperature is 30-40°C, and the activation time is 1 ~2h, the flow rate of the mixed gas of hydrogen fluoride and nitrogen is 100-120mL / min, and the catalyst aluminum fluoride is generated through the activation reaction of hydrogen fluoride and aluminum oxide. Since the activation reaction of the catalyst is a strong exothermic process, the pore structure of the catalyst, The specific surface area and crystal phase composition change, and the reaction is carried out under the condition of diluting hydrogen fluoride with nitrogen gas, which can improve the activity of the catalyst, and is beneficial to improve the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com