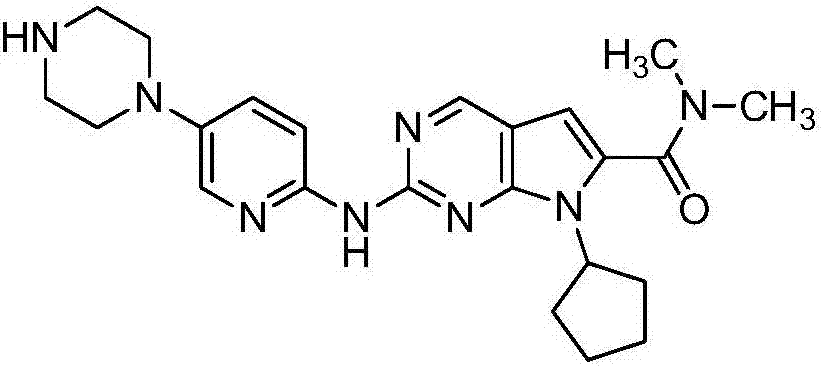

Preparation method of ribociclib intermediate

A compound and reaction technology, applied in the field of organic synthesis and drug synthesis, can solve problems such as low product yield, low conversion rate of raw materials, and many impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

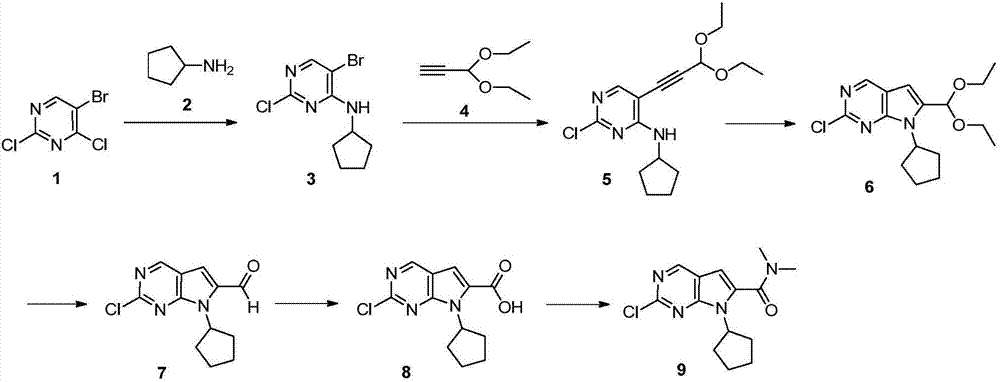

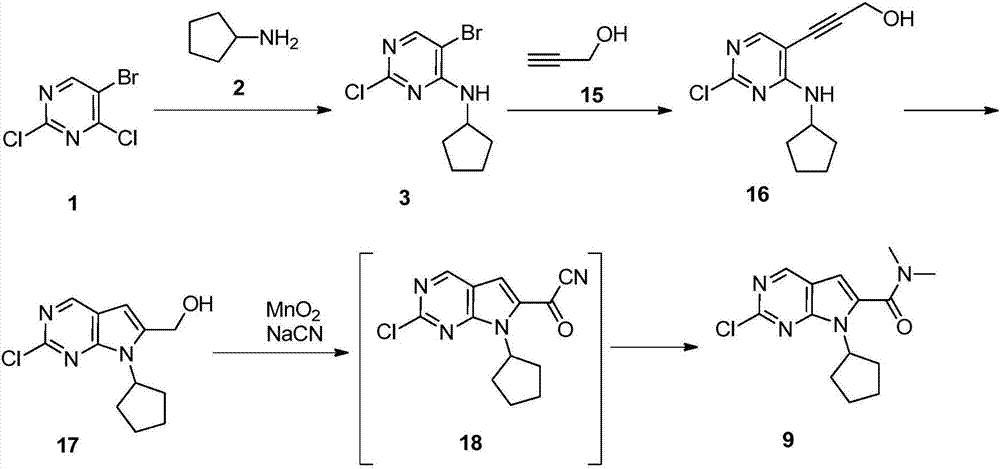

Method used

Image

Examples

Embodiment 1

[0095] Example 1: 2-Chloro-N-cyclopentyl-5-(3-((tetrahydro-2H-pyran-2-yl)oxy)prop-1-yn-1-yl)pyrimidine-4- Preparation of amine (compound of formula Ⅲ-1)

[0096]

[0097] 5-bromo-2-chloro-N-cyclopentylpyrimidin-4-amine (60g, 218mmol), tetrabutylammonium fluoride trihydrate (103g, 326mmol), bis(triphenylphosphine) dichloro Palladium chloride (7.6g, 10.85mmol) and anhydrous tetrahydrofuran (550mL) were added to the reaction flask, under nitrogen protection, 2-(prop-2-yn-1-yloxy)tetrahydro-2H-furan (compound of formula II ) (45.6g, 325.5mmol), after reflux reaction for 24 hours, HPLC analysis showed that the reaction was complete. The reaction solution was cooled to room temperature, tetrahydrofuran was distilled off under reduced pressure, ethyl acetate (500 mL) was added, and washed successively with saturated sodium bisulfate (400 mL×3), water (400 mL×3), and saturated brine (400 mL×1). The organic phase was separated and concentrated under reduced pressure to obtain a cr...

Embodiment 2

[0100] Example 2: 2-Chloro-N-cyclopentyl-5-(3-((tetrahydro-2H-pyran-2-yl)oxy)prop-1-yn-1-yl)pyrimidine-4- Preparation of amine (compound of formula Ⅲ-1)

[0101] 5-bromo-2-chloro-N-cyclopentylpyrimidin-4-amine (20g, 72.3mmol), tetrabutylammonium fluoride trihydrate (57g, 180.8mmol), tetrakis (triphenylphosphine) Palladium (4.2g, 3.62mmol) and anhydrous tetrahydrofuran (300mL) were added to the reaction flask, and under nitrogen protection, 2-(prop-2-yn-1-yloxy)tetrahydro-2H-furan (20.3g, 144.6 mmol), after reacting for 20 hours at 75°C, HPLC analysis showed that the reaction was complete. The reaction solution was cooled to room temperature, tetrahydrofuran was distilled off under reduced pressure, ethyl acetate (300 mL) was added, and washed successively with saturated sodium bisulfate (200 mL×3), water (200 mL×3), and saturated brine (200 mL×1). The organic phase was separated and concentrated under reduced pressure to obtain a crude oil, which was separated by silica gel ...

Embodiment 3

[0102] Example 3: 2-Chloro-N-cyclopentyl-5-(3-((tetrahydro-2H-pyran-2-yl)oxy)prop-1-yn-1-yl)pyrimidine-4- Preparation of amine (compound of formula Ⅲ-1)

[0103] 5-bromo-2-chloro-N-cyclopentylpyrimidin-4-amine (30g, 108.5mmol), tetrabutylammonium fluoride (70.8g, 271.3mmol), bis(triphenylphosphine) dichloro Palladium chloride (7.6g, 10.85mmol) and anhydrous tetrahydrofuran (300mL) were added to the reaction flask, under nitrogen protection, 2-(prop-2-yn-1-yloxy)tetrahydro-2H-furan (22.8g, 162.8mmol), after reacting at 75°C for 20 hours, HPLC analysis showed that the reaction was complete. The reaction solution was cooled to room temperature, tetrahydrofuran was distilled off under reduced pressure, ethyl acetate (300 mL) was added, and washed successively with saturated sodium bisulfate (200 mL×3), water (200 mL×3), and saturated brine (200 mL×1). The organic phase was separated and concentrated under reduced pressure to obtain a crude oil, which was separated by silica gel ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com