Liquid straw composting agent

The technology of straw decomposing agent and liquid inoculum is applied in the directions of organic fertilizers, microorganisms, fungi, etc., which can solve the problems of unsatisfactory decomposing effect, single mixing of inoculum freeze-dried powder, and few functional strains, so as to shorten the decomposing effect. Time, faster decomposition rate, less antagonistic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

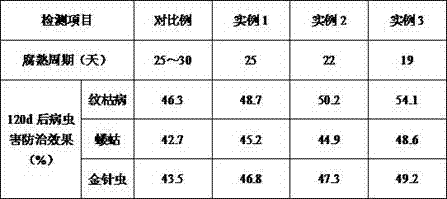

example 1

[0018] Weigh the straw, put it into a shredder and cut it into 5cm small pieces and mix it to obtain a mixed straw section, mix the mixed straw section with the garden soil at a mass ratio of 1:20, add 0.1% sucrose of the garden soil quality after mixing, and stir for 10 minutes Sealed and fermented at a temperature of 35°C and a relative humidity of 60% for 3 days to obtain a fermentation substrate, weighed 20 g of the fermentation substrate and added it to 800 mL of sterile water, stirred for 10 min, soaked for 5 h, and filtered to obtain a seed liquid. In terms of parts by weight, 50 parts of sucrose, 60 parts of peptone, 3 parts of potassium dihydrogen phosphate, 0.3 parts of magnesium sulfate heptahydrate, 3 parts of calcium carbonate, and 2 parts of ammonium dihydrogen phosphate were selected and added to 800 parts of deionized water, stirred and mixed After 10 minutes, sterilize under ultraviolet light for 15 minutes to obtain a liquid medium, inoculate the seed liquid i...

example 2

[0020]Weigh the straw, put it into a shredder and cut it into small pieces of 6 cm and mix it to obtain a mixed straw section. Mix the mixed straw section with the garden soil at a mass ratio of 1:20, add 0.2% sucrose of the garden soil quality after mixing, and stir for 15 minutes Sealed and fermented at a temperature of 38°C and a relative humidity of 65% for 4 days to obtain a fermentation substrate, weighed 25 g of the fermentation substrate and added it to 900 mL of sterile water, stirred for 15 minutes, soaked for 6 hours, and filtered to obtain a seed solution. In terms of parts by weight, 60 parts of sucrose, 70 parts of peptone, 4 parts of potassium dihydrogen phosphate, 0.4 parts of magnesium sulfate heptahydrate, 4 parts of calcium carbonate, and 3 parts of ammonium dihydrogen phosphate were selected and added to 900 parts of deionized water, stirred and mixed After 13 minutes, sterilize under ultraviolet light for 18 minutes to obtain a liquid medium, inoculate the ...

example 3

[0022] Weigh the straw, put it into a shredder and cut it into small pieces of 7 cm and mix it to obtain a mixed straw section. Mix the mixed straw section with the garden soil at a mass ratio of 1:20, add 0.3% sucrose of the garden soil quality after mixing, and stir for 20 minutes Sealed and fermented at a temperature of 40°C and a relative humidity of 70% for 5 days to obtain a fermentation substrate; weigh 30 g of the fermentation substrate and add it to 1000 mL of sterile water, stir for 20 minutes, soak for 7 hours, and filter to obtain a seed solution. In terms of parts by weight, 70 parts of sucrose, 80 parts of peptone, 5 parts of potassium dihydrogen phosphate, 0.5 parts of magnesium sulfate heptahydrate, 5 parts of calcium carbonate, and 4 parts of ammonium dihydrogen phosphate were selected and added to 1000 parts of deionized water, stirred and mixed After 15 minutes, sterilize under ultraviolet light for 20 minutes to obtain a liquid medium, inoculate the seed liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com