High velocity oxy-fuel sheet type part deformation compensation method

A supersonic flame and deformation compensation technology, which is applied in coating, fusion spraying, metal material coating process, etc., can solve the problems of adverse effects on the subsequent assembly of parts, great difficulty, and limited degree of deformation compensation of parts. To achieve the effect of ensuring the effect of subsequent use and improving the shape and position tolerance of flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

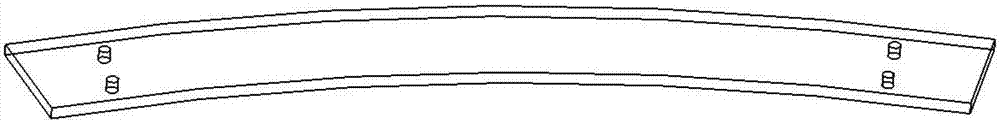

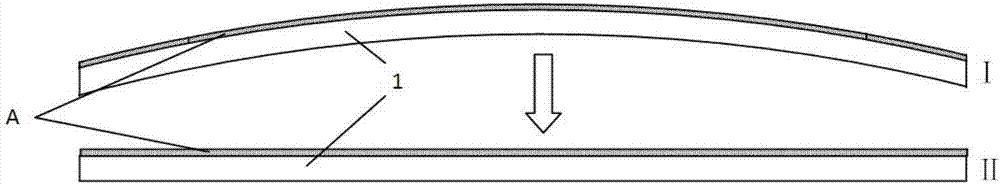

[0025] For such as figure 1 The thin-plate-shaped part 1 shown first uses tungsten carbide / cobalt as the spraying material, adopts the supersonic flame spraying process, the spray gun moving speed is 800mm / s, the step distance is 3mm, and the interval between each spraying is 25s. The surface of the thin-plate-shaped part is sprayed Spray 16 times to prepare a tungsten carbide / cobalt cermet coating A with a thickness of about 130 μm. After the supersonic flame spraying tungsten carbide / cobalt coating process Ⅰ, the thin plate-shaped parts were turned over and fixed in the same way, and the Al particles with a particle size of 75-125 μm 2 o 3 For spraying powder, control the spraying distance of 200mm, powder feeding rate of 15g / min, oxygen pressure of 145psi, nitrogen pressure of 130psi, propane pressure of 75psi, hydrogen pressure of 90psi, air pressure of 100psi, oxygen flow rate of 180SLPM, propane flow rate of 55SLPM, and air flow rate of 400SLPM. HVOF Coating Al 2 o 3...

Embodiment 2

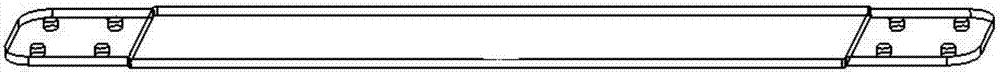

[0027] For such as image 3 The thin-plate-shaped part 2 shown first uses nickel-chromium-aluminum-yttrium (NiCrAlY) as the spraying material, adopts the supersonic flame spraying process, the spray gun moving speed is 1000mm / s, the step distance is 4mm, and the interval time between each spraying is 20s. The sprayed surface of the part was sprayed 10 times to prepare a NiCrAlY metal coating B with a thickness of about 220 μm. After the supersonic flame spraying tungsten carbide / cobalt coating process Ⅰ, the thin plate-shaped parts were turned over and fixed in the same way, and ZrO with a particle size of 80-100 μm 2 For spraying powder, control the spraying distance of 210mm, powder feeding rate of 17g / min, oxygen pressure of 150psi, nitrogen pressure of 140psi, propane pressure of 80psi, hydrogen pressure of 90psi, air pressure of 100psi, oxygen flow rate of 200SLPM, propane flow rate of 60SLPM, and air flow rate of 400SLPM. Supersonic flame spraying of ZrO on the non-spra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| surface smoothness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com