An electrical control system for a decarbonization production line

An electrical control system and production line technology, applied in the direction of electrical program control, general control system, control/adjustment system, etc., can solve the problems of inability to use custom standard function modules, lack of hardware design, and non-expandability, etc., to achieve full play of equipment Potential, increase production efficiency, reduce the effects of overdependence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

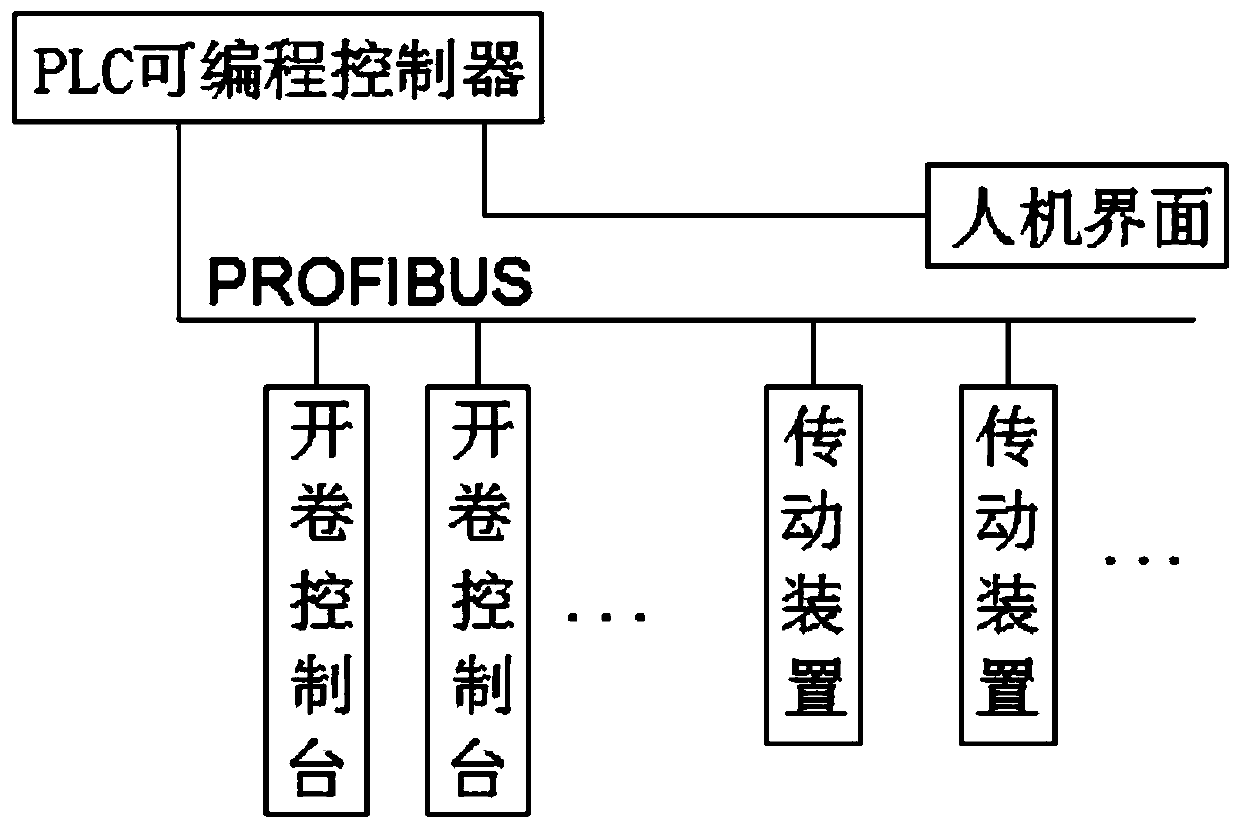

[0026] Such as figure 1 As shown, the electrical control system of the decarbonization production line of the present invention includes a PLC programmable controller, a man-machine interface, several unwinding consoles and several transmission devices, wherein:

[0027] The PLC programmable controller adopts SIEMENS S7-300, which has short cycle time, high processing speed, powerful instruction set (including more than 350 instructions), and can be used for complex functions.

[0028] The man-machine interface adopts HMI color LCD touch screen, which has good operation performance and intelligent display. The man-machine interface is electrically connected with the PLC programmable controller.

[0029] The unwinding console adopts ET200M, which can connect 256 I / O channels, which is suitable for large-scale, high-performance applications. The unwinding console and PLC programmable controller are connected through PROFIBUS communication.

[0030] The transmission device adopt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com