Preparation method and application of graphene @ metal phosphide @ carbon nano composite material

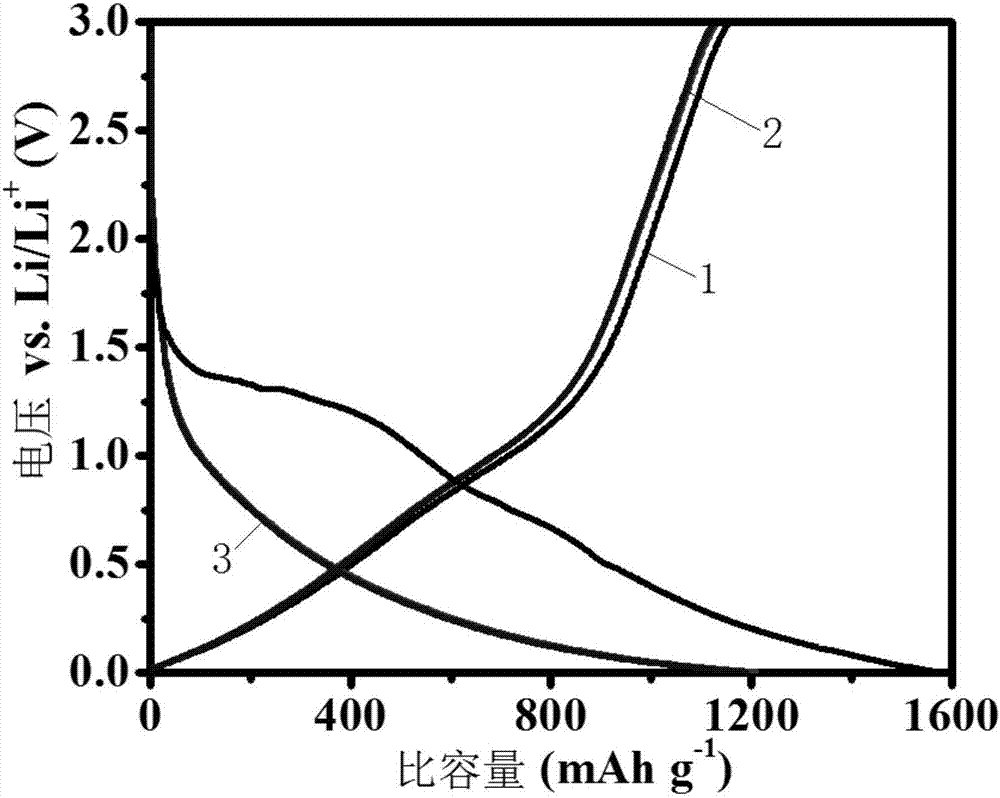

A nanocomposite material, metal phosphide technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of metal phosphide poor electrical conductivity, poor reaction reversibility, easy to expand, etc. Achieve the effect of improving the characteristics of lithium/sodium storage, low cost, and enhanced conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

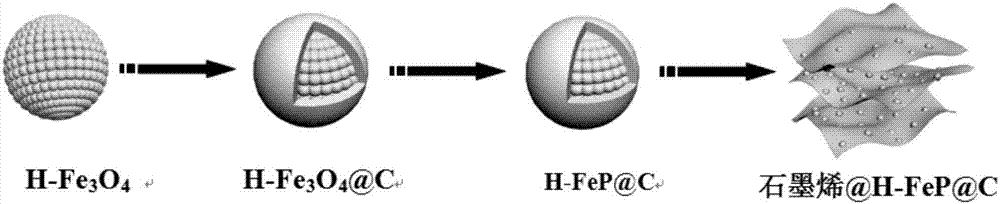

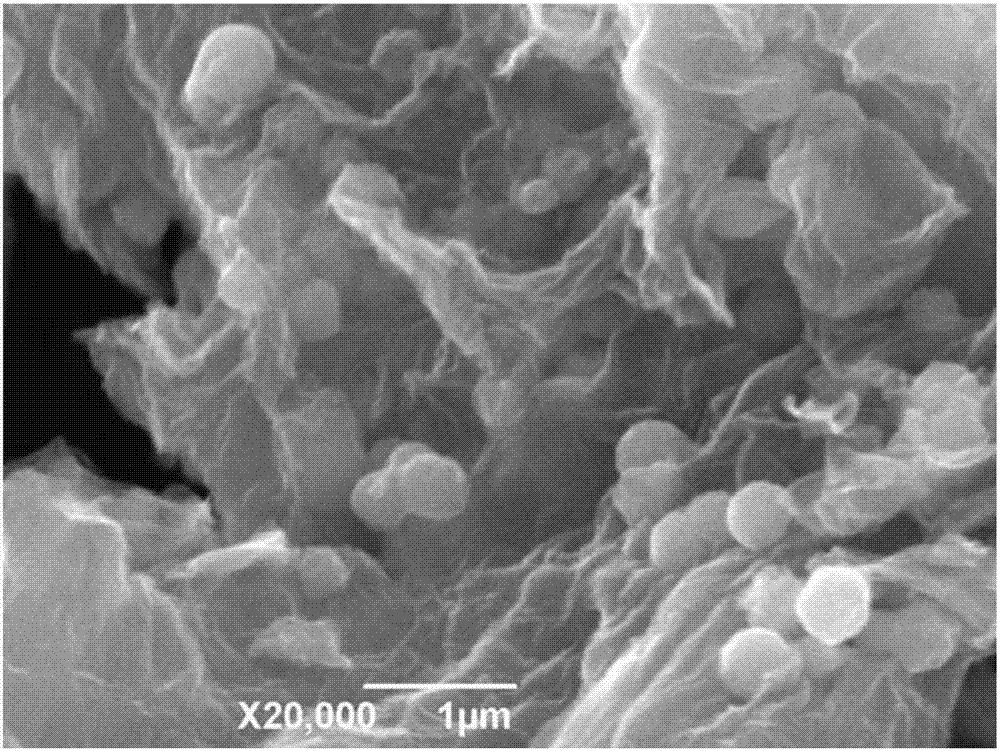

[0036] Specific implementation mode 1: This implementation mode is a preparation method of graphene@metal phosphide@C nanocomposite material, which is specifically completed according to the following steps:

[0037] 1. Preparation of metal oxide nanospheres:

[0038] Dissolve metal chloride salt and sodium acetate in ethylene glycol, and then ultrasonically disperse for 20-40 minutes to obtain a mixed solution; transfer the mixed solution to a hydrothermal reaction kettle, and then react at a temperature of 180°C-220°C for 6h- 10h, and then naturally cooled to room temperature to obtain the reaction product I; first, use distilled water to wash the reaction product I for 3 to 5 times, and then use absolute ethanol to wash the reaction product I for 3 to 5 times, and then at a temperature of 60°C to Dry at 80°C for 10h to 12h to obtain metal oxide nanospheres;

[0039] Metal chloride salt described in step 1 is FeCl 3 ·6H 2 O, CoCl 2 ·6H 2 O, NiCl 2 ·6H 2 O, SnCl4 ·5H ...

specific Embodiment approach 2

[0061] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the ultrasonic power in step 1 is 20W-40W. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0062] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the particle size of the metal oxide nanospheres described in Step 1 is 200nm-400nm. Other steps are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com