Tobacco humectant of amino acid type natural eutectic solvent and the preparation method and application

A deep eutectic solvent and amino acid-based technology, applied in the field of tobacco additives, can solve problems such as increased content of harmful substances, achieve the effects of improving taste, improving processing resistance, and improving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

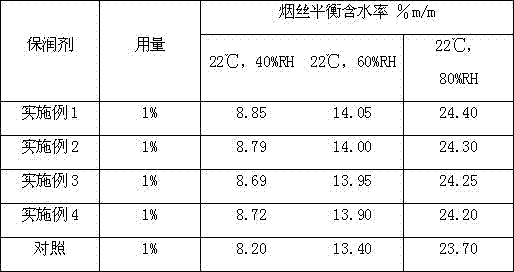

Examples

Embodiment 1

[0015] Embodiment 1. Weigh D / L-proline racemate and sorbitol solid powder, according to molar ratio 1:1, total weight is 100g, join in the round bottom flask, add the water of 30 milliliters simultaneously, 60 o C was added in a water bath and stirred until a transparent liquid was formed, and the reaction time in the water bath was 2.5 hours. Add 300 milliliters of water to the synthesized D / L-proline-sorbitol natural deep eutectic solvent, add dropwise a mass fraction of 5% sodium hydroxide solution to adjust the pH to be neutral, add 1.2g preservative and 1.2g Defoamer can be used to prepare D / L-proline-sorbitol natural deep eutectic solvent humectant. Weigh 10g of humectant and spray evenly onto 1000g of shredded tobacco. The amount of humectant is 1% of the mass of tobacco leaves. Cigarette samples were prepared from the shredded tobacco.

Embodiment 2

[0016] Embodiment 2. Weigh D / L-proline racemate and lactic acid solid powder, according to molar ratio 1:1, total weight is 100g, join in the round bottom flask, add the water of 20 milliliters simultaneously, 60 o C water bath was added and stirred until a transparent liquid was formed, and the water bath reaction time was 3 hours. Add 200 ml of water to the synthesized D / L-proline-lactic acid natural deep eutectic solvent, add dropwise 5% sodium hydroxide solution to adjust the pH to neutral, add 1.0 g preservative and 1.0 g disinfectant The D / L-proline-lactic acid natural deep eutectic solvent humectant can be prepared by using a foaming agent. Weigh 10g of humectant and spray evenly onto 1000g of shredded tobacco. The amount of humectant is 1% of the mass of tobacco leaves. Cigarette samples were prepared from the shredded tobacco.

Embodiment 3

[0017] Embodiment 3. Weigh serine and glucose solid powder, according to molar ratio 5:3, total weight is 100g, joins in the round bottom flask, 50 o C water bath was added and stirred until a transparent liquid was formed, and the water bath reaction time was 2 hours. Add the synthesized serine-glucose natural deep eutectic solvent to 300 ml of water, add dropwise 5% sodium hydroxide solution to adjust the pH to neutral, add 1.2g preservative and 1.2g defoamer to prepare serine - Dextrose natural deep eutectic solvent humectant. Weigh 10g of humectant and spray evenly onto 1000g of shredded tobacco. The amount of humectant is 1% of the mass of tobacco leaves. Cigarette samples were prepared from the shredded tobacco.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com