A loaded zno/al with a flaky appearance 2 o 3 Composite photocatalytic film and preparation method thereof

A composite photocatalytic and supported technology, applied in catalyst activation/preparation, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve problems such as limitations, low specific surface area, and low porosity , to achieve the effect of good combination, good application prospect and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) 7075 aluminum alloy substrate pretreatment: the 7075 aluminum alloy substrate is successively water-grinded with 220#, 400#, 1000#, 2000#, 5000# sandpaper until the surface is smooth, and ultrasonically cleaned with absolute ethanol and distilled water respectively ;

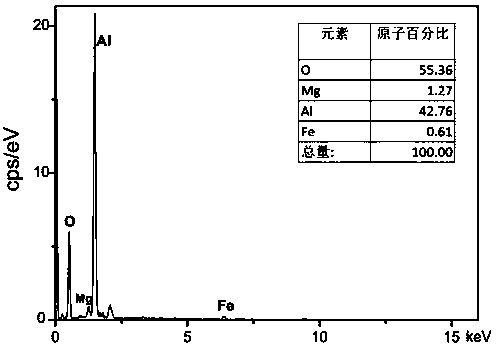

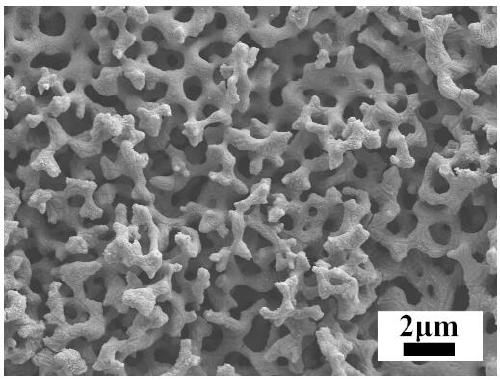

[0028] (2) Preparation of plasma electrolytic oxidation carrier film: prepare electrolyte solution A containing 6 g / L sodium aluminate, 12 g / L potassium hydroxide, 4 g / L potassium ferrocyanide and solvent distilled water; ) The pretreated substrate is connected to the anode of the DC power supply, and the stainless steel sheet is used as the cathode, and the plasma electrolytic oxidation treatment is performed in the electrolyte solution A, the reaction voltage is 300V, and the reaction time is 120 min, and the plasma electrolytic oxidation carrier film is prepared;

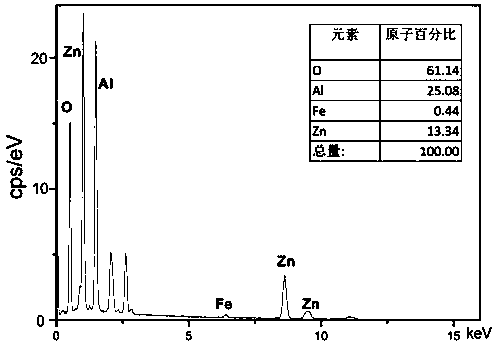

[0029] (3) Electrodeposition treatment: Prepare electrolyte solution B containing 5 mM zinc nitrate, 5 mM urotropine, 0.5 M potassium c...

Embodiment 2

[0032] (1) 7075 aluminum alloy substrate pretreatment: the 7075 aluminum alloy substrate is successively water-grinded with 220#, 400#, 1000#, 2000#, 5000# sandpaper until the surface is smooth, and ultrasonically cleaned with absolute ethanol and distilled water respectively ;

[0033] (2) Preparation of plasma electrolytic oxidation carrier film: prepare electrolyte solution A containing 4 g / L sodium aluminate, 10 g / L potassium hydroxide, 2 g / L potassium ferrocyanide and solvent distilled water; ) The pretreated substrate is connected to the anode of the DC power supply, and the stainless steel sheet is used as the cathode, and the plasma electrolytic oxidation treatment is performed in the electrolyte solution A, the reaction voltage is 280V, and the reaction time is 60 min to prepare the plasma electrolytic oxidation carrier film;

[0034] (3) Electrodeposition treatment: prepare electrolyte solution B containing 1 mM zinc nitrate, 1 mM urotropine, 0.1 M potassium chloride...

Embodiment 3

[0037] (1) 7075 aluminum alloy substrate pretreatment: the 7075 aluminum alloy substrate is successively water-grinded with 220#, 400#, 1000#, 2000#, 5000# sandpaper until the surface is smooth, and ultrasonically cleaned with absolute ethanol and distilled water respectively ;

[0038] (2) Preparation of plasma electrolytic oxidation carrier film: prepare electrolyte solution A containing 8 g / L sodium aluminate, 16 g / L potassium hydroxide, 6 g / L potassium ferrocyanide and solvent distilled water; ) The pretreated substrate was connected to the anode of the DC power supply, and the stainless steel sheet was used as the cathode. The plasma electrolytic oxidation treatment was carried out in the electrolyte solution A, the reaction voltage was 320 V, and the reaction time was 120 min. The plasma electrolytic oxidation support film was prepared ;

[0039] (3) Electrodeposition treatment: Prepare electrolyte solution B containing 4 mM zinc nitrate, 4 mM urotropine, 0.4 M potassiu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com