Ethylene trimerization/tetramerization catalyst composition and application thereof

A technology of ethylene trimerization and composition, which is applied in the direction of catalysts, hydrocarbons, hydrocarbons, etc., can solve the problems of restricting industrial scale-up, generating more polymers, and only importing them, and achieves ultra-high polymerization reactivity, Response triggers fast, smooth-running effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

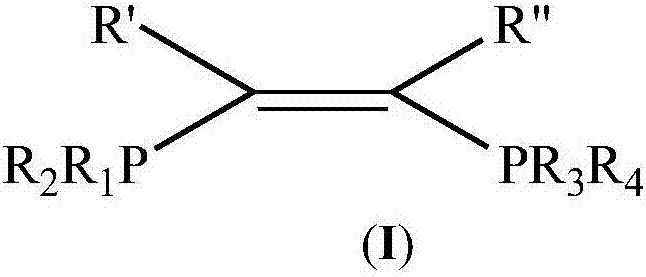

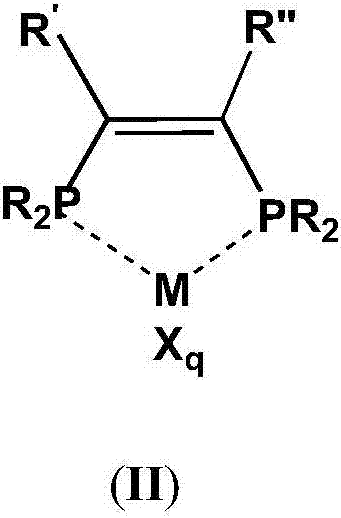

Method used

Image

Examples

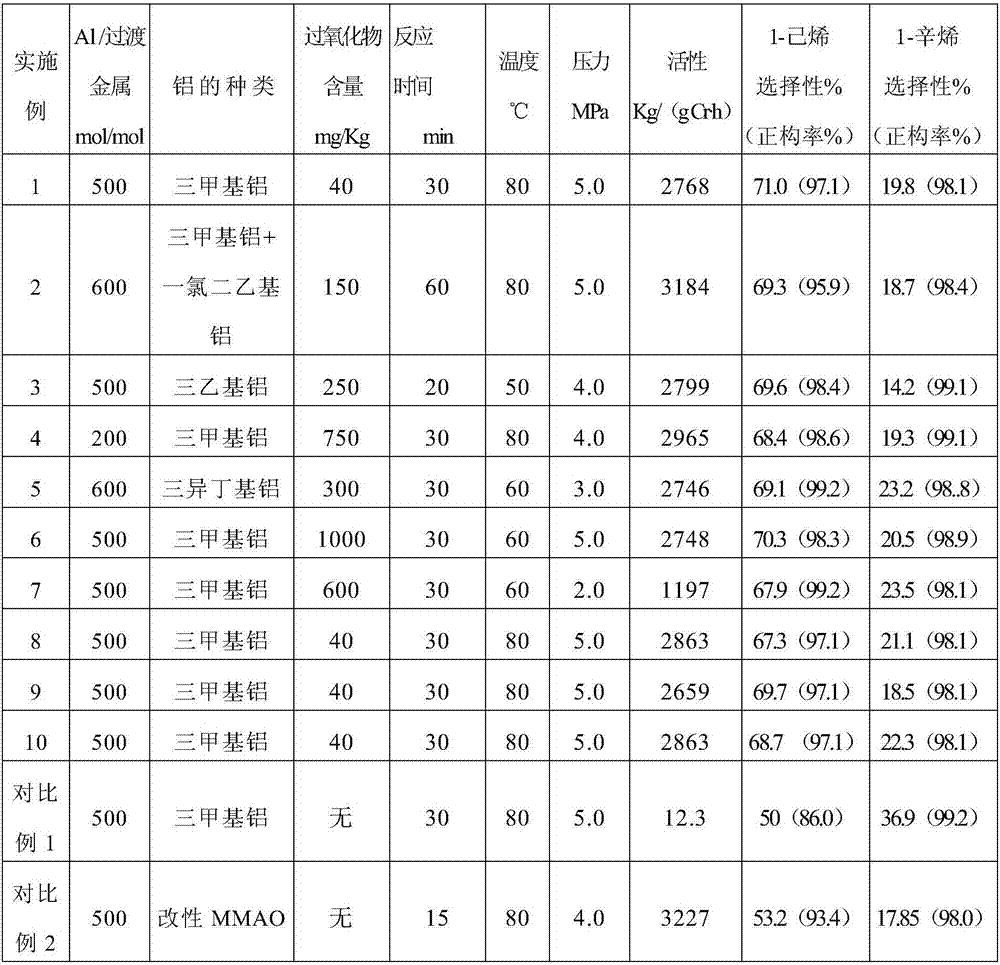

Embodiment 1

[0035] A 500ml stainless steel polymerization kettle was used for the polymerization reaction. First, the pressure-holding test was carried out on the reaction kettle. Under the condition that the sealing of the reaction kettle was confirmed, vacuum drying was carried out at 120°C for 4 hours, and then the temperature was lowered to 80°C and replaced with ethylene gas three times. Add solvent n-heptane, trimethylaluminum, tert-butyl hydroperoxide to the reaction kettle in turn, start stirring and premix for 3 minutes, then add a chromium complex solution containing 1 μmol of chromium to the reaction kettle, and the bisphosphine compound R in the body 1 -R 4 All are o-methoxyphenyl, R' is methyl, R" is tert-butyl; the chromium compound used is chromium acetylacetonate. The total volume of the resulting composition is 100ml, based on the weight of the organic solvent, the tert-butyl The content of hydrogen oxide is 40mg / Kg.Al / Cr ratio is 500.Control reaction pressure 5.0MPa, f...

Embodiment 2

[0039] The specific steps are the same as in Example 1, except that the cocatalyst is an equimolar mixed solution of trimethylaluminum and diethylaluminum chloride, the Al / Cr ratio is 600, and the tert-butyl hydroperoxide content is 150mg / Kg , the reaction time is 1 hour. The results of ethylene oligomerization are shown in Table 1.

Embodiment 3

[0041] The concrete steps are the same as in Example 1, except that the cocatalyst is triethylaluminum, and the Al / Cr ratio is 500. In the bisphosphine ligand, R' is a tert-butyl group, and R" is a cyclopropyl group, and the reaction temperature is 50 ℃. ℃, the pressure is 4.0MPa, the content of tert-butyl hydroperoxide is 250mg / Kg, and the reaction time is 20 minutes. The ethylene oligomerization reaction results are shown in attached table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com