Thick oil sewage treating agent as well as preparation method and application thereof

A technology of heavy oily sewage and treatment agent, which is applied in water/sewage treatment, water/sludge/sewage treatment, water/sewage treatment with added substances, etc. It can solve the problem of slow sedimentation or floating speed, poor effect of oil removal and water purification , Weaken flocculation and other problems, to achieve the effect of clear water, easy to control, and fast deposition speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

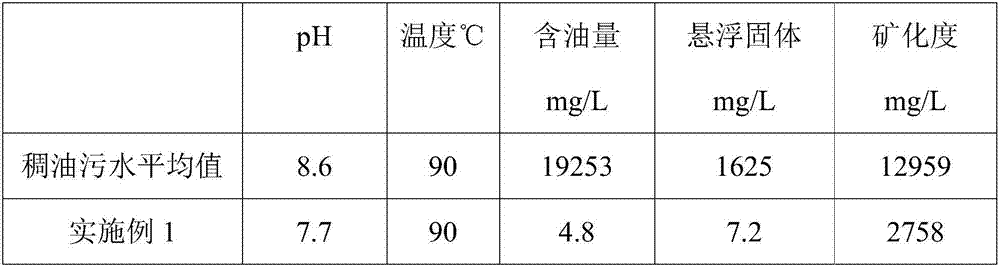

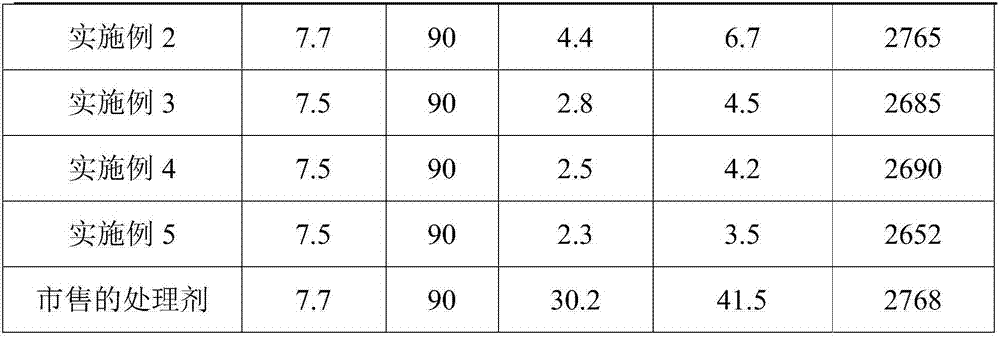

Examples

Embodiment 1

[0018] In the embodiment of the present invention, a heavy oil sewage treatment agent is composed of the following raw materials in parts by weight: 7 parts of urea peroxide, 15 parts of tartaric acid, 1 part of alkylphenol polyoxyethylene ether, 33 parts of calamine, silicon Magnesium acid 11 parts.

[0019] Tartaric acid is mixed with deionized water to prepare a tartaric acid solution with a mass content of 18%. Calamine and magnesium silicate were mixed and ground for 1 hour, then mixed with tartaric acid solution, heated to 79°C, and stirred at this temperature for 1.5 hours; then ultrasonically treated for 1.5 hours with an ultrasonic power of 700W to prepare mixture A. Cool the mixture A to 58°C, then add urea peroxide, and stir at a stirring speed of 100r / min for 1h, then add alkylphenol polyoxyethylene ether, at a temperature of 72°C, at a stirring speed of 150r / min Stir for 1.8 hours, dry and place at 220°C for 1 hour to obtain the treatment agent.

Embodiment 2

[0021] In the embodiment of the present invention, a heavy oil sewage treatment agent is composed of the following raw materials in parts by weight: 15 parts of urea peroxide, 25 parts of tartaric acid, 5 parts of alkylphenol polyoxyethylene ether, 41 parts of calamine, silicon Magnesium acid 19 parts.

[0022] Tartaric acid and deionized water are mixed to prepare a tartaric acid solution with a mass content of 25%. Calamine and magnesium silicate were mixed and ground for 1.2h, then mixed with tartaric acid solution, heated to 82°C, and stirred at this temperature for 1.8h; then ultrasonically treated for 1.8h with ultrasonic power of 700W to prepare mixture A. Cool mixture A to 62°C, then add urea peroxide, and stir at a stirring speed of 130r / min for 1.2h, then add alkylphenol polyoxyethylene ether, at a temperature of 75°C, stirring at a speed of 200r / min Stir at low temperature for 2 hours, dry and place at 250°C for 1.5 hours to obtain the treatment agent.

Embodiment 3

[0024] In the embodiment of the present invention, a heavy oil sewage treatment agent is composed of the following raw materials in parts by weight: 9 parts of urea peroxide, 18 parts of tartaric acid, 2 parts of alkylphenol polyoxyethylene ether, 35 parts of calamine, silicon Magnesium acid 13 parts.

[0025] Tartaric acid is mixed with deionized water to prepare a tartaric acid solution with a mass content of 22%. Calamine and magnesium silicate were mixed and ground for 1.1h, then mixed with tartaric acid solution, heated to 80°C, and stirred at this temperature for 1.6h; then ultrasonically treated for 1.6h with ultrasonic power of 700W to prepare mixture A. Cool mixture A to 60°C, then add urea peroxide, and stir at a stirring speed of 120r / min for 1.1h, then add alkylphenol polyoxyethylene ether, at a temperature of 73°C, stirring at a speed of 180r / min Stir for 1.9 hours, dry and place at 230°C for 1.2 hours to obtain the treatment agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com