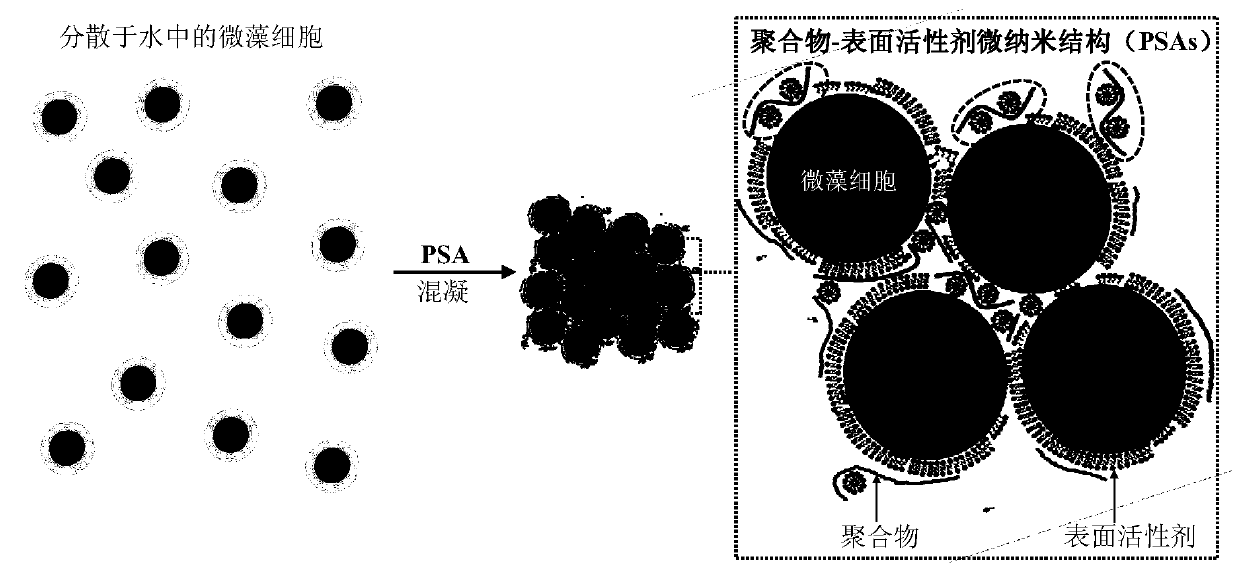

Algae Concentration and Harvesting Method Based on Polymer-Surfactant Binary Micro-Nano Structure

A technology of surfactant and micro-nano structure, which is applied in the field of concentrated harvesting of algae based on polymer-surfactant binary micro-nano structure, can solve the problems of long harvesting process, high operating cost, complicated operation, etc. Harvesting process, enhanced van der Waals forces, high mechanical strength effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

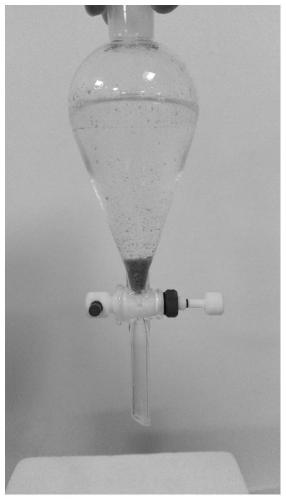

[0040] The binary system of PAA and CPC was used to harvest Chlorella pyrenoidosa ZTY4. Before harvest, the biomass concentration of Chlorella ZTY4 in the culture medium was 1.43 g / L. Add 150ppm PAA and 1.5mM CPC to the culture medium, stir continuously with a magnetic stirrer at a speed of 200rpm for 20min, pour the mixture into a separatory funnel, and let it settle for 25min. The result is as follows: figure 2 shown. It can be seen that the dense flocs have completely settled at the bottom of the separatory funnel, and there are almost no suspended algal cells in the supernatant. Sampling and determination of the algae biomass concentration in the supernatant was only 0.12g / L, that is, the harvesting efficiency of the PAA and CPC binary system to Chlorella ZTY4 can reach 91.6%. Use a 100 μm coarse filter membrane to intercept and harvest the flocs at the bottom of the separatory funnel, weigh them, then place them at 60°C to dry to constant weight, and weigh them again. ...

Embodiment 2

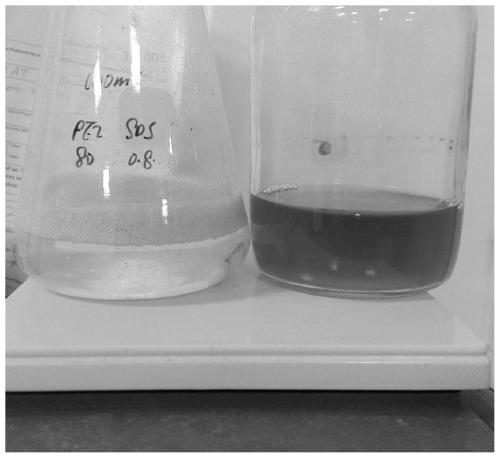

[0042] Synechococcus 7002 was harvested using PEI and SDS binary system. Before harvesting, the biomass concentration of Synechococcus 7002 in the culture solution is 1.26g / L, and the culture solution is as image 3 shown on the right. Add 80ppm PEI and 0.8mM SDS to the culture solution, stir continuously with a magnetic stirrer at a speed of 200rpm for 20min, and directly intercept and harvest the flocs formed by a coarse filter membrane. The obtained filtrate is as follows: image 3 shown on the left. The concentration of algal biomass in the filtrate was measured by sampling, and it was only 0.08g / L, that is, the harvesting efficiency of Synechococcus 7002 by the binary system of PEI and SDS could reach 93.6%. The moisture content of the harvested biomass measured by the same method as in Example 1 was only 65.4%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com