Preparation method of submicron-nano lithium metal particles

A nano-metal and sub-micron technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of large median particle size of metal lithium powder, strong corrosion of metal lithium, and complicated preparation methods, and achieve low vapor pressure and production. Low cost and improved reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] In a glove box under an argon atmosphere, 10 mL of N-propyl-N-methylpyrrolidine bis(trifluoromethanesulfonyl)imide salt ([C 3 mPyr + ][TFSI - ]) into a stainless steel ball mill jar, then heated to 250 ° C, and kept for 1 hour to remove the moisture. [C 3 mPyr + ][TFSI - ] Cool down to 170°C, add 1.5g of lithium particles with a particle size between 1 and 2mm; use an ultrasonic crusher to perform ultrasonic crushing, keep the ultrasonic power at 60W, and the ultrasonic time is 30 minutes; after washing the obtained product with n-hexane, After centrifugation and drying, metal lithium particles are obtained.

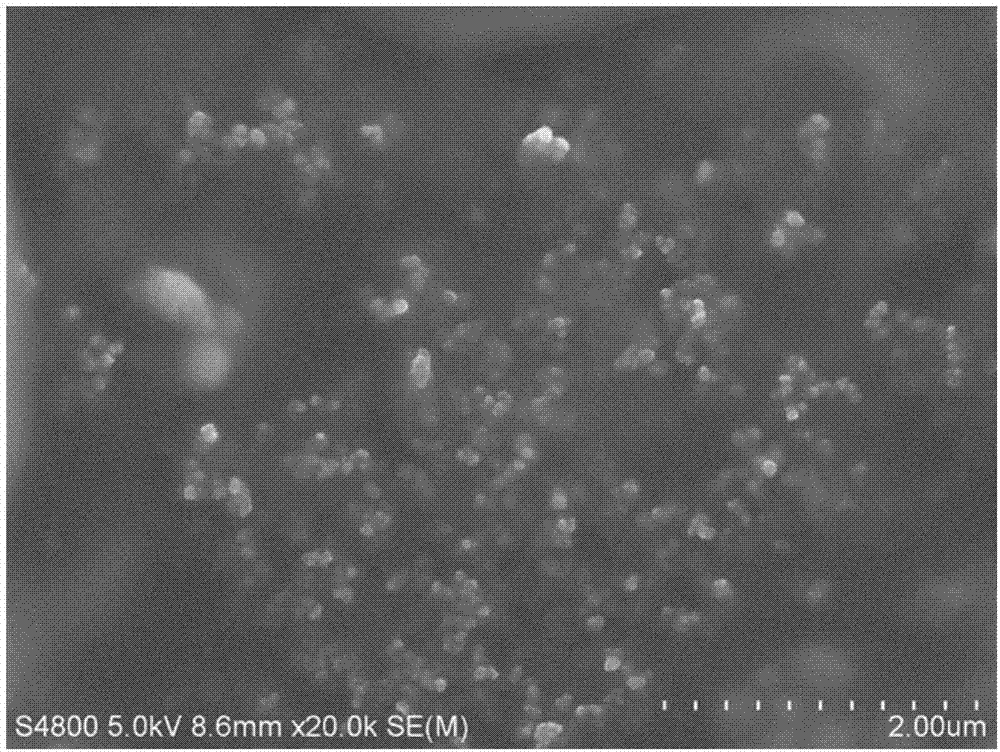

[0037] figure 1 The scanning electron microscope image of the prepared metal lithium particles, the scanning electron microscope image shows that the shape of the prepared metal lithium particles is relatively regular, generally spherical, and the particle size of the metal lithium particles is mainly distributed in the range of 10-100nm.

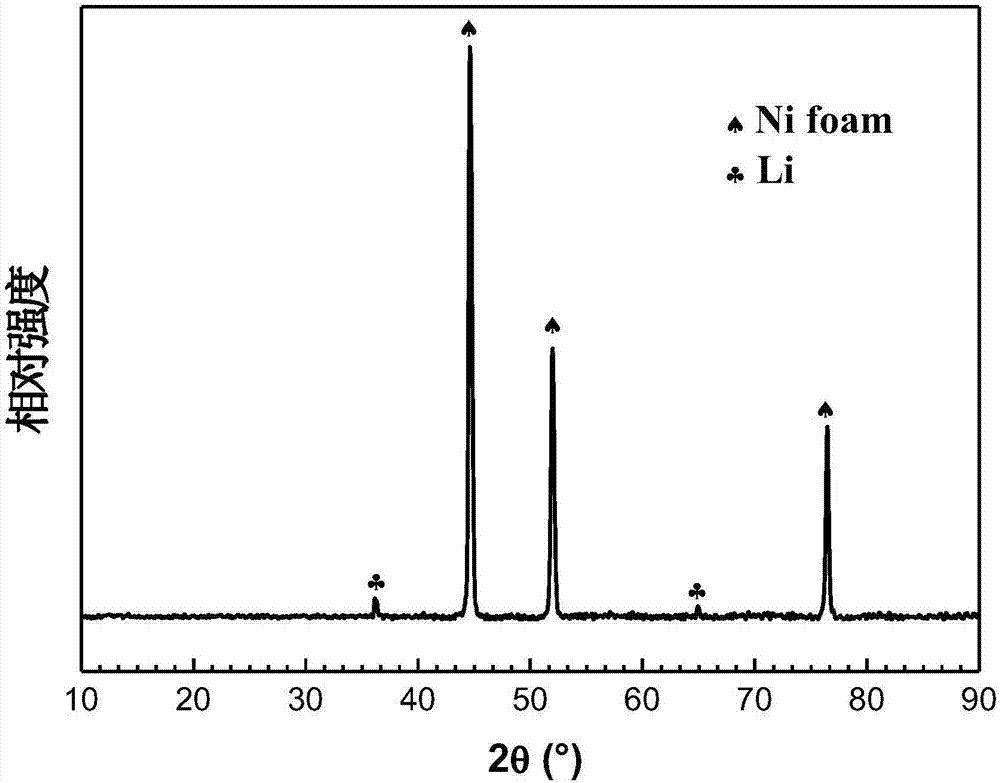

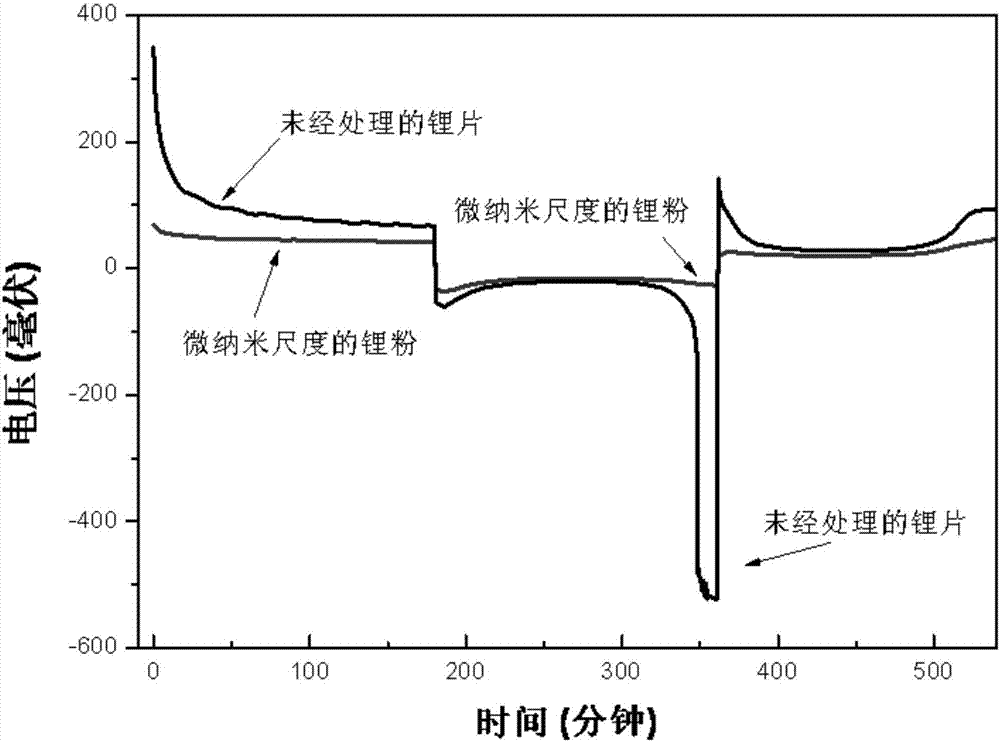

[0038] Nickel fo...

Embodiment 2

[0043] In dry air, 8 mL of N-butyl-N-methylpyrrolidine bis(fluoromethanesulfonyl)imide ([C 4 mPyr + ][FSI - ]) in a plastic centrifuge tube, and then heated to 300 ° C, and kept for 4 hours to remove the water. Then [C 3 mPyr + ][FSI - ] Cool down to 160°C, add 3.5g of lithium particles with a particle size of 3 to 5mm, and start ultrasonic crushing using an ultrasonic crusher with an ultrasonic power of 100W and a crushing time of 2.5 hours. The product is washed with diethyl carbonate, centrifuged and dried to obtain metal lithium particles, and the particle diameter of the obtained metal lithium particles is below 300 nanometers.

Embodiment 3

[0045] In a glove box under an argon atmosphere, 50 mL of N-butyl-N-methylpiperidine bis(trifluoromethanesulfonyl)imide salt ([Pp 14 + ][TFSI - ]) into a plastic bottle with a cap, then heated to 200° C. and kept for 8 hours to remove moisture. Then [Pp 14 + ][TFSI - ] Cool down to 150°C, add 7.5g of electrode-grade lithium flakes with a diameter of 10mm and a thickness of 0.7mm, and start ultrasonic crushing using an ultrasonic crusher with an ultrasonic power of 250W and a crushing time of 15 minutes. The product is washed with 1,3-dioxolane, and then subjected to vacuum filtration to obtain metal lithium particles, and the particle diameter of the obtained metal lithium particles is below 500 nanometers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com