A method for processing pine wood

A technology of wood and sylvestris, which is applied in the field of wood product processing and production, can solve the problems such as the decline of mechanical properties of sylvestris pine, and achieve the effects of improving oil removal effect, good environmental protection, and enhanced shear strength along the grain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

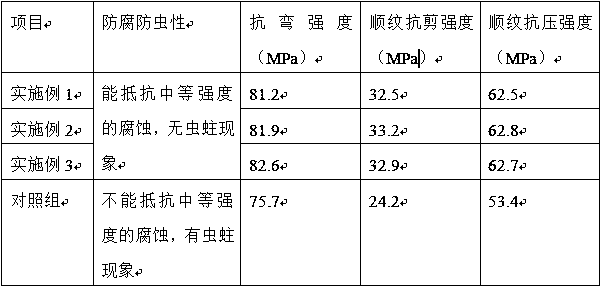

Examples

Embodiment 1

[0017] A method for processing pine wood, comprising the following steps:

[0018] (1) Put pine logs in the sun for 3 days, remove part of the moisture, and soak them in a degreasing agent for 4 hours. The degreasing agent is made of the following ingredients in terms of mass percentage: tripropylene glycol n-butyl ether accounts for 3.5% , Isopropanol 2.3%, Ethanolamine 1.2%, Sodium Lauryl Sulfate 1.0%, Sodium Silicate 0.8%, Trisodium Phosphate 0.5%, Sodium Carbonate 0.3%, Sodium Hydroxide 0.1%, Alumina powder accounts for 0.03%, and the rest is water;

[0019] (2) Immediately after degreasing, rinse the wood surface with water at 30°C, then wrap the wood surface with plastic wrap for 2 layers, and use a fumigant to evenly fumigate for 1 hour at a temperature of 70°C. The fumigant used is made of camphor bark , mugwort leaves, tea bark, and hyssop mixed with essential oils, after fumigation, heat the wood under steam at 100°C for 10 minutes;

[0020] (3) Put the steam-heate...

Embodiment 2

[0026] A method for processing pine wood, comprising the following steps:

[0027] (1) Put pine logs in the sun for 4 days, remove part of the water, and soak them in degreasing agent for 5 hours. The degreasing agent is made of the following ingredients in terms of mass percentage: tripropylene glycol n-butyl ether accounts for 3.55% , Isopropanol 2.4%, Ethanolamine 1.25%, Sodium Lauryl Sulfate 1.1%, Sodium Silicate 0.9%, Trisodium Phosphate 0.6%, Sodium Carbonate 0.4%, Sodium Hydroxide 0.15%, Alumina powder accounts for 0.04%, and the rest is water;

[0028] (2) Rinse the wood surface with 35°C water immediately after degreasing, then wrap the wood surface with two layers of plastic wrap, and use fumigant to evenly fumigate for 1.5 hours at a temperature of 75°C. The fumigant used is made of camphor bark , mugwort leaves, tea bark, and hyssop mixed with essential oils, after fumigation, heat the wood under steam at 100°C for 15 minutes;

[0029] (3) Put the steam-heated wo...

Embodiment 3

[0035] A method for processing pine wood, comprising the following steps:

[0036] (1) Put pine logs in the sun for 5 days, remove part of the moisture, and soak them in degreasing agent for 6 hours. The degreasing agent is made of the following ingredients in terms of mass percentage: tripropylene glycol n-butyl ether accounts for 3.6% , Isopropanol 2.6%, Ethanolamine 1.3%, Sodium Lauryl Sulfate 1.2%, Sodium Silicate 1.0%, Trisodium Phosphate 0.7%, Sodium Carbonate 0.5%, Sodium Hydroxide 0.2%, Alumina powder accounts for 0.06%, and the rest is water;

[0037] (2) Immediately after degreasing, use 40°C water to rinse the wood surface, then wrap the wood surface with three layers of plastic wrap, and use fumigant to evenly fumigate for 2 hours. The fumigation temperature is 80°C. The fumigant used is made of camphor bark , mugwort leaves, tea bark, and hyssop mixed with essential oils, after fumigation, heat the wood under steam at 100°C for 20 minutes;

[0038] (3) Put the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com