A method to improve the matching degree of strength and plasticity of metal gradient structures

A gradient structure and matching technology, applied in the field of material processing, can solve the problems of increased roughness, decreased plasticity, increased strength, etc., to achieve the effect of reducing roughness, simple process, and retaining work hardening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

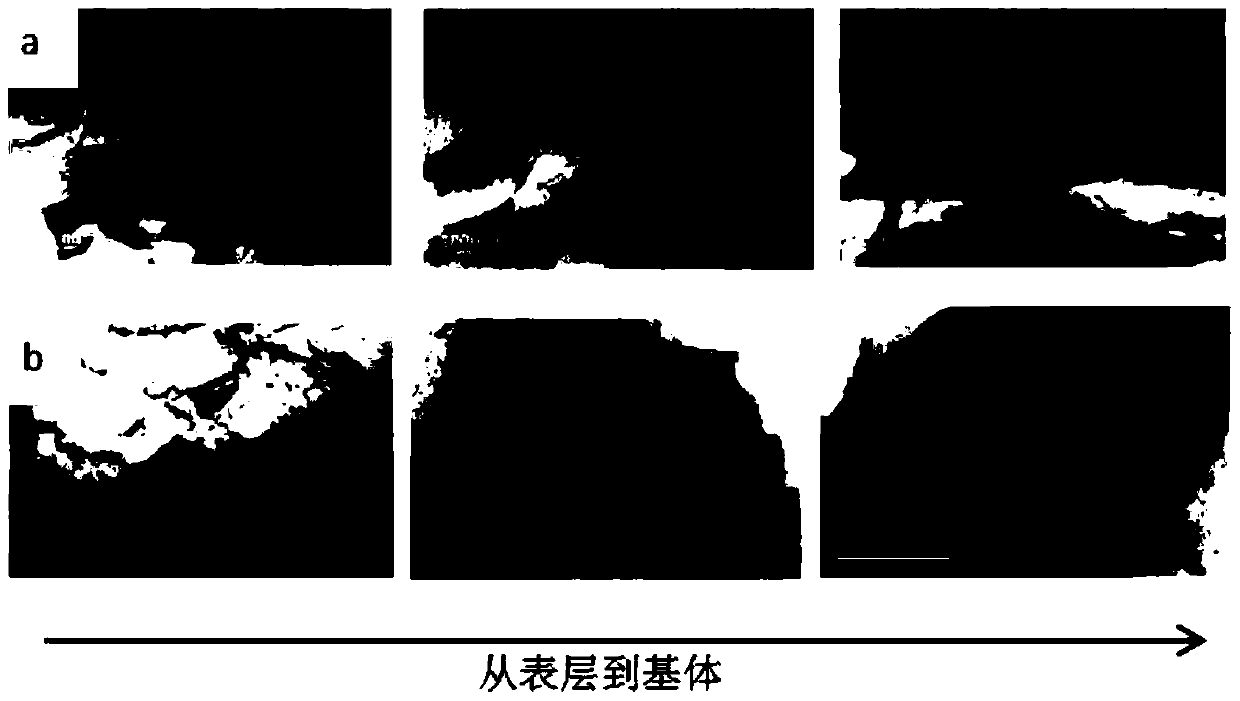

[0025] ①Cutting: Prepare an annealed 6063 aluminum alloy plate with a thickness of 10mm, ensuring that the upper and lower surfaces are parallel; ②Surface cleaning: Use alcohol and other organic solvents to remove the grease on the upper and lower sides of the plate at room temperature. ③Surface nano treatment: choose 5mm GCr15 steel shot. The speed of high-energy shot peening equipment is 25m / s, and the processing time is 15min. ④Flat rolling: two-roll four-roll rolling mill (two-roll Φ400mm×350mm; four-roll cold rolling: Φ100mm / Φ380mm×350mm). Rolling is carried out on the plate after the surface nano treatment, keeping a small amount of deformation in each pass, the total deformation amount is 12%, 4 passes, and the rolling speed is 5m / s. The sample thickness is sequentially from 10mm, to 9.5mm, to 9.0mm, to 8.8mm. ⑤ Low temperature and short time annealing: Vacuum annealing furnace anneals the finished products obtained after shot peening and rolling at 50°C, 75°C, and 10...

Embodiment 2

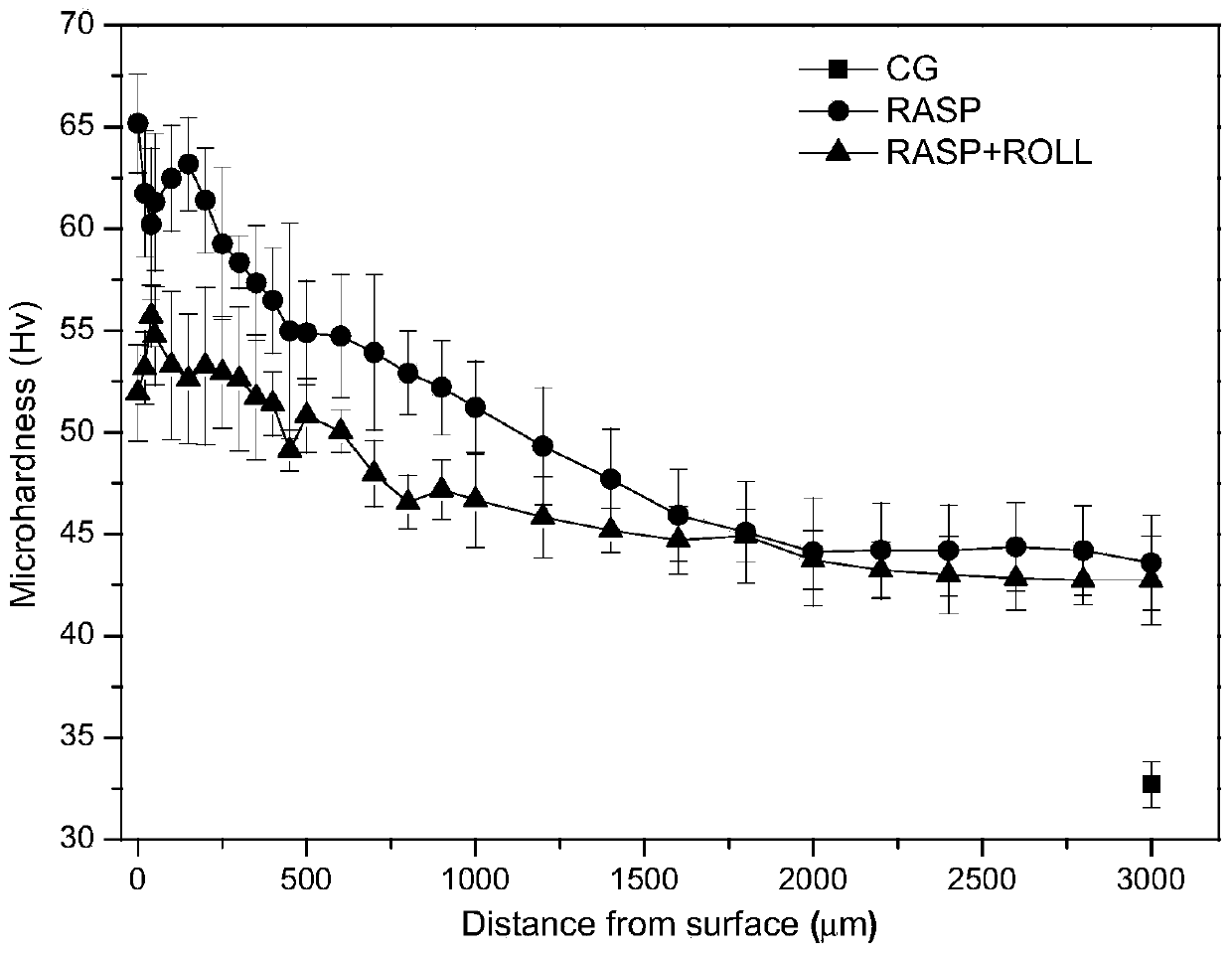

[0031] ① Cutting: prepare a piece of annealed 99.99wt% pure copper plate with a thickness of 4.7mm, ensuring that the upper and lower surfaces are parallel; ② Surface cleaning: use alcohol and other organic solvents to remove the grease on the upper and lower sides of the plate at room temperature. ③Surface nano treatment: choose 3mm GCr15 steel shot. The speed of the high-energy shot peening equipment is 25m / s, and the processing time is 30min. ④Flat rolling: two-roll four-roll rolling mill (two-roll Φ400mm×350mm; four-roll cold rolling: Φ100mm / Φ380mm×350mm). Rolling is carried out on the plate after the surface nano treatment, keeping a small amount of deformation in each pass, the total deformation amount is 30%, 7 passes, and the rolling speed is 40m / s. The sample thickness was reduced from 4.7mm to 3.3mm. ⑤ Low temperature and short time annealing: Vacuum annealing furnace anneals the finished products obtained after shot peening and rolling at 50°C, 75°C, and 100°C for...

Embodiment 3

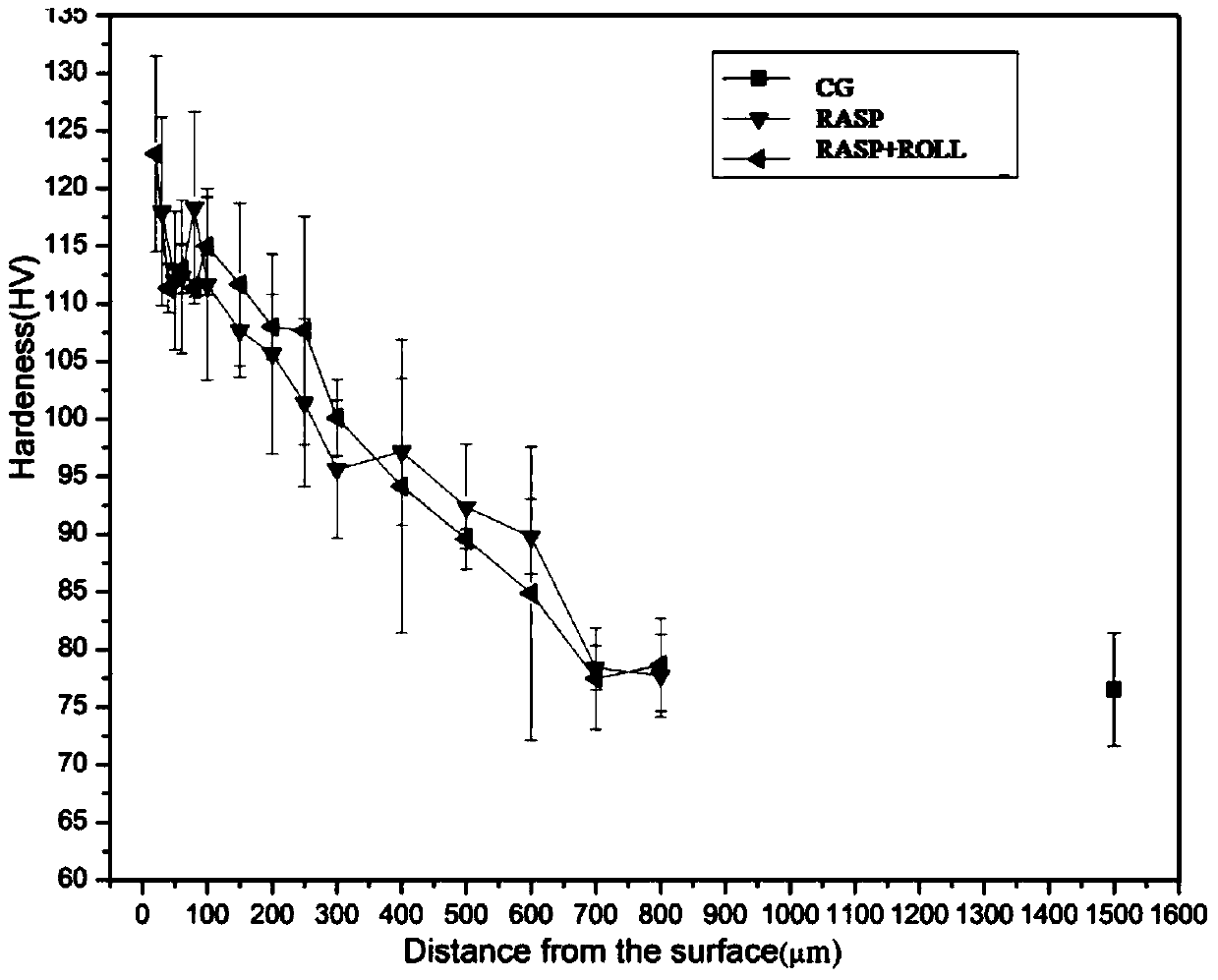

[0037]①Cutting: Prepare an annealed 6063 aluminum alloy plate with a thickness of 12mm, ensuring that the upper and lower surfaces are parallel; ②Surface cleaning: Use alcohol and other organic solvents to remove the grease on the upper and lower sides of the plate at room temperature. ③Surface nano treatment: choose 5mm GCr15 steel shot. The speed of high-energy shot peening equipment is 25m / s, and the processing time is 15min. ④Flat rolling: two-roll four-roll rolling mill (two-roll Φ400mm×350mm; four-roll cold rolling: Φ100mm / Φ380mm×350mm). Rolling is carried out on the plate after surface nano-treatment, keeping a small amount of deformation in each pass, with a total deformation amount of 50%, and 8 passes. The sample thickness ranges from 12mm to 6mm.

[0038] Table 3 Roughness and maximum hardness of coarse-grained aluminum, aluminum alloy plate after surface nano-treatment by high-energy shot peening, and aluminum alloy plate after shot peening and rolling

[0039] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com