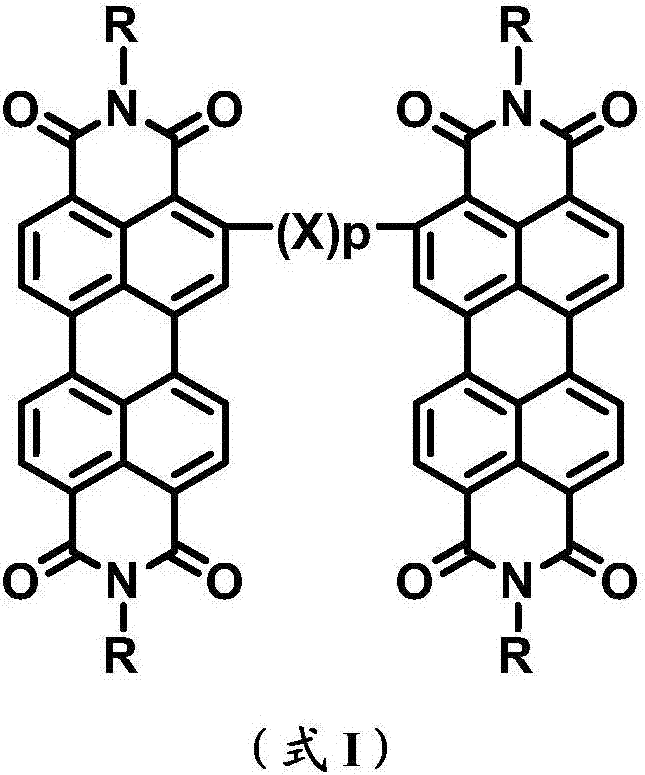

Ortho-bridged perylene diimide dimer, preparation method and application thereof in organic photovoltaic devices

A perylene diimide dimer and dimer technology, which is applied in the fields of electric solid-state devices, semiconductor devices, semiconductor/solid-state device manufacturing, etc., can solve the problem of effective transport of unfavorable carriers and destroy the order of the PDI molecular π system Sexuality, deformation and other problems, to reduce the effect of excessive aggregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Embodiment 1: Preparation of PDI monomer 1a substituted by ortho-position Br

[0058]

[0059] Ortho Br-substituted PDI monomer 1a according to the literature (K.Müllen et al, Org. Lett., 2011, 13, 3012-3015; H.Shinokubo et al, Org. Lett., 2011, 13, 2532-2535) method of preparation.

Embodiment 2

[0060] Embodiment 2: preparation compound 2a

[0061]

[0062] The product 1a (855.6 mg, 1.1 mmol) was dissolved in 15 mL of toluene, and commercially available thiophene-2,5-di-tributyltin (332.1 mg, 0.5 mmol) and Pd (PPh 3 ) 4 (34.7mg, 0.03mmol), under the heating condition of 120°C, the reaction was stirred for 36 hours. The toluene in the reaction system was distilled off under reduced pressure to obtain a red-black solid, which was dissolved in a mixed solvent of 50 mL of dichloromethane and 50 mL of water, the dichloromethane layer was collected by liquid separation, and the dichloromethane was distilled off under reduced pressure to obtain a red The black solid was passed through the H60 silica gel column to obtain the product 2a (628.2 mg, 0.425 mmol, yield: 85%). 1 H NMR (400MHz, CDCl 3 ):δppm:8.68-8.62(m,14H),7.49-7.37(m,2H),5.21-5.13(m,4H),2.28-2.21(m,8H),1.87-1.80(m,8H),1.36 -1.15(m,48H),1.14-0.96(m,24H). MS(MALDI-TOF):m / z=1477.2[M+H] + .

Embodiment 3

[0063] Example 3: Preparation of Trimethyltin Derivatives Used in Examples 4-7

[0064] Oligothiophene was synthesized according to the literature (N.Tamaoki et al, J.Am.Chem.Soc., 2006, 128, 10930-10933).

[0065] The trimethylstanning reaction was prepared as follows: oligothiophene, selenophene, benzene, or furan (1 mmol) was dissolved in 10 mL of anhydrous THF. Argon protection, cooled to -78 ℃. A commercially available 2.2 mol / L n-butyllithium solution in n-hexane (1 mL, 2.2 mmol) was slowly added. After stirring at -78°C for 2 hours, a commercially available 1 mol / L (25 wt.%) trimethyltin chloride solution in n-hexane (2.5 mL, 2.5 mmol) was added. After the reaction system was warmed to room temperature, stirring was continued for 2 hours. The mixed solution was diluted with 50 mL of ethyl acetate. After washing three times with water, dry and spin dry. The residue was recrystallized with methanol at -20°C, and the corresponding trimethyltin derivatives could be sep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com