Method for preparing hydroxylamine hydrochloride

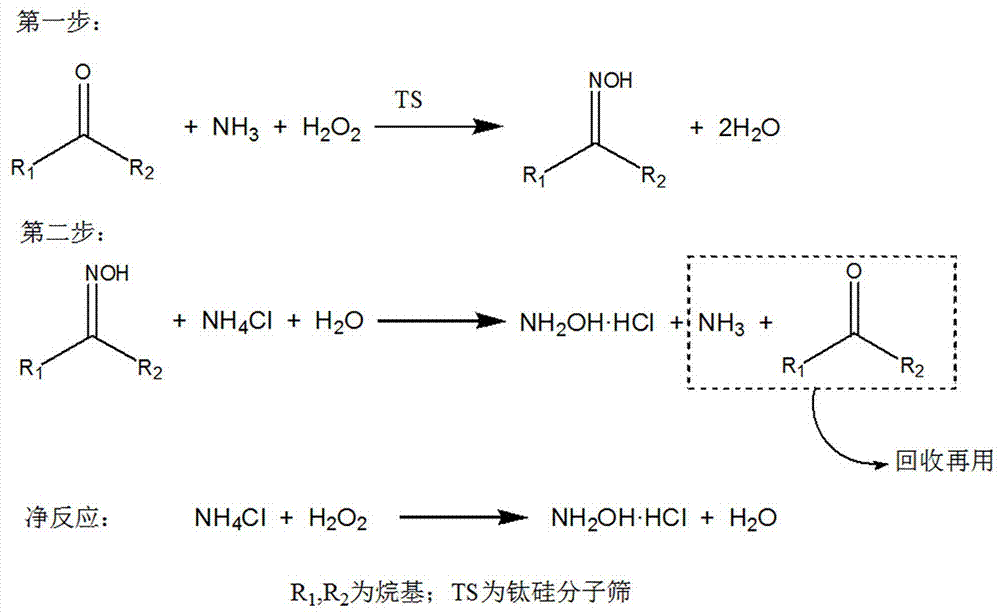

A technology of hydroxylamine hydrochloride and ketoxime, which is applied in the field of preparation of hydroxylamine hydrochloride, can solve the problems of high cost and many by-products, and achieve the effects of low cost, mild reaction conditions, and promotion of sustainable development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The first step, ketoxime synthesis: 5 kg of Ti-MWW molecular sieve, 36 kg of methyl ethyl ketone, and 100 kg of water are added to the reactor together, and the water bath is heated to 60 ° C, and then 75 kg of ammonia water and 68 kg of hydrogen peroxide are added to Add the uniform rate into the reactor within 90 minutes, keep the temperature of the water bath and the stirring speed constant during the whole process, after the reaction is completed, absorb the unreacted ammonia gas under reduced pressure, let it stand, and release the lower water phase with a separatory funnel, and use diethyl ether The butanone oxime is extracted, and the obtained butanone oxime is mixed with the oil phase to obtain a crude butanone oxime.

[0026] The second step, preparation of hydroxylamine hydrochloride: take 45 kg of water, add 13.5 kg of ammonium chloride, add 43 kg of the crude butanone oxime obtained in the first step, heat to 70°C to make it react, reduce the pressure to a va...

Embodiment 2

[0029] The first step, synthesis of ketoxime: add 10 kg of TS-1 molecular sieve, 29 kg of acetone, and 100 kg of water as a solvent into the reactor together, heat the water bath to 60 ° C, and then mix 75 kg of ammonia water and 68 kg of hydrogen peroxide in a uniform The rate is added to the reactor within 90 minutes, and the temperature of the water bath and the stirring speed are kept constant throughout the process. After the reaction, the unreacted ammonia gas is absorbed under reduced pressure. After standing still, the lower water phase is released with a separatory funnel, and extracted with ether. The acetone oxime, the obtained acetone oxime is mixed with the oil phase to obtain the crude acetone oxime.

[0030] The second step, preparation of hydroxylamine hydrochloride: take 45 kg of water, add 13.5 kg of ammonium chloride, add 43 kg of acetone oxime crude product obtained in the first step, heat to 100°C to make it react, depressurize to a vacuum of 50KPa to absor...

Embodiment 3

[0033] The first step, ketoxime synthesis: add 10 kg of Ti-MOR molecular sieve, 36 kg of butanone, and 100 kg of water into the reactor together, heat the water bath to 60 ° C, and then add 75 kg of ammonia water and 68 kg of hydrogen peroxide to Add the reactor at a uniform rate within 90 minutes, keep the temperature of the water bath and the stirring speed constant throughout the process, after the reaction is over, absorb the unreacted ammonia under reduced pressure, let it stand still, use a separatory funnel to release the lower aqueous phase, and extract it with ether For the butanone oxime, the obtained butanone oxime is mixed with the oil phase to obtain the crude butanone oxime.

[0034] The second step, the production of hydroxylamine hydrochloride: take 45 kg of water, add 13.5 kg of ammonium chloride, add 43 kg of the crude butanone oxime obtained in the first step, heat to 85 ° C to make it react, reduce the pressure to a vacuum of 80 KPa to absorb the reaction to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com