P-type indium phosphide single crystal preparation formula and preparation method

A technology of indium phosphide and single crystal, which is applied in the field of preparation formula and preparation of P-type indium phosphide single crystal, which can solve the problems of single crystal difficulty and high twinning frequency, and achieve uniform electrical parameters, small residual stress and dislocation density low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

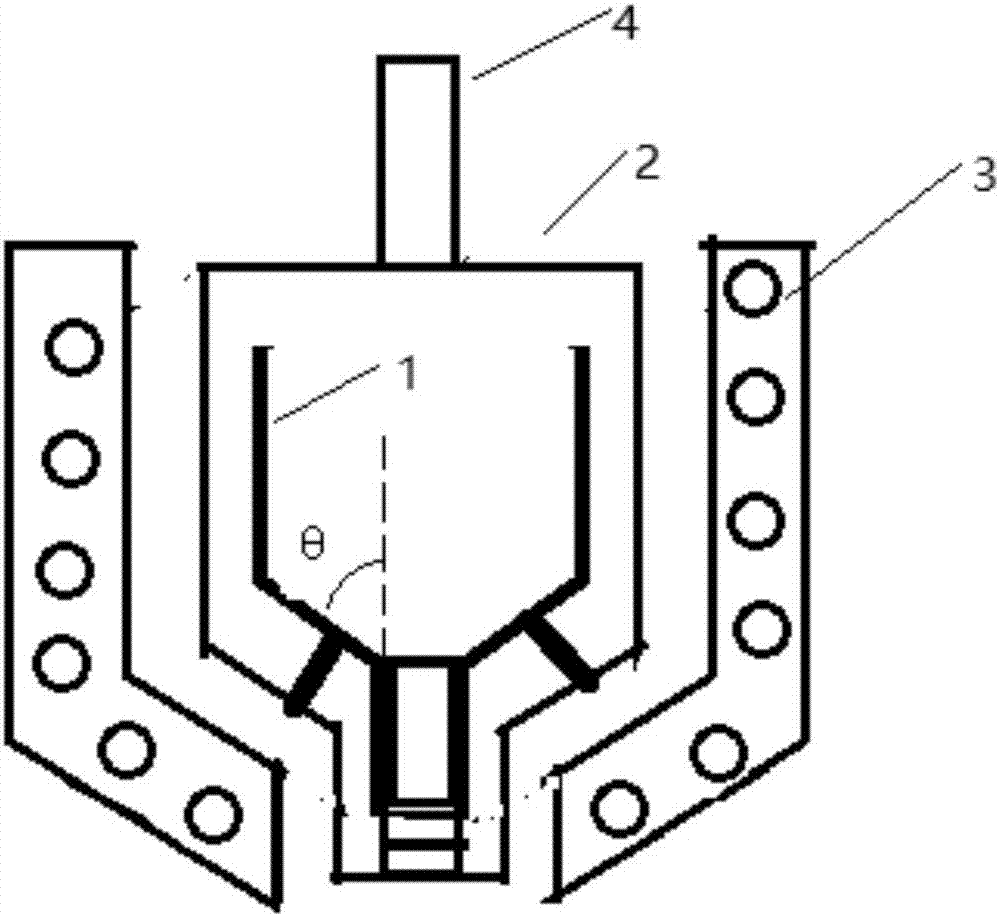

Image

Examples

Embodiment 1

[0016] Embodiment 1: Production of 100 grams of P-type indium phosphide single crystal

[0017] The raw materials are composed of: 99.5 grams of InP polycrystalline material, 0.2-0.8 grams of elemental zinc, more than 32 grams of diboron trioxide and red phosphorus, and the amount of phosphorus is calculated according to the ideal gas state equation, wherein the pressure is controlled at 2.7-3.5 MPa, the temperature is controlled at 1062-1100°C, and the InP polycrystalline material is boiled and washed with deionized water several times to remove oxides and residual impurities on the surface; the diboron trioxide is high-purity dehydrated diboron trioxide , the water content of boron trioxide after dehydration is on the order of 500ppm; the red phosphorus reaches 6N purity; the zinc reaches 6N purity.

[0018] The growth method of the indium phosphide single crystal comprises the following steps: using the vertical temperature gradient solidification method, loading the InP se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com