Oxide nanowire-MOF derivative/S composite positive electrode material and preparation method therefor

A composite positive electrode material and composite material technology, applied in the field of oxide nanowire-MOF derivative/S composite positive electrode material and its preparation, can solve the problems of accelerating the commercialization of lithium-sulfur batteries, unstable cycle performance, poor conductivity, etc. , to achieve the effect of meeting the needs of industrial production, unique shape, and improving conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] In step 1, first dissolve 0.04g of manganese oxide nanowires in 20mL of methanol solvent, and disperse evenly by ultrasonic; at the same time, take 0.2g of 2-methylimidazole and dissolve them in 10mL of solvent, and disperse evenly; Add 0.1g of PVP, and ultrasonically disperse evenly; then, add 0.1g of cobalt nitrate hexahydrate to the solution with PVP, and ultrasonically disperse evenly; finally, mix the methanol solution of 2-methylimidazole with the solution containing cobalt nitrate hexahydrate, seal Let the reaction stand for at least 20 hours, wash the reaction product with methanol three times, and dry at 60°C to obtain ZIF-67-MnO 2 NWs are materials with a unique serial structure.

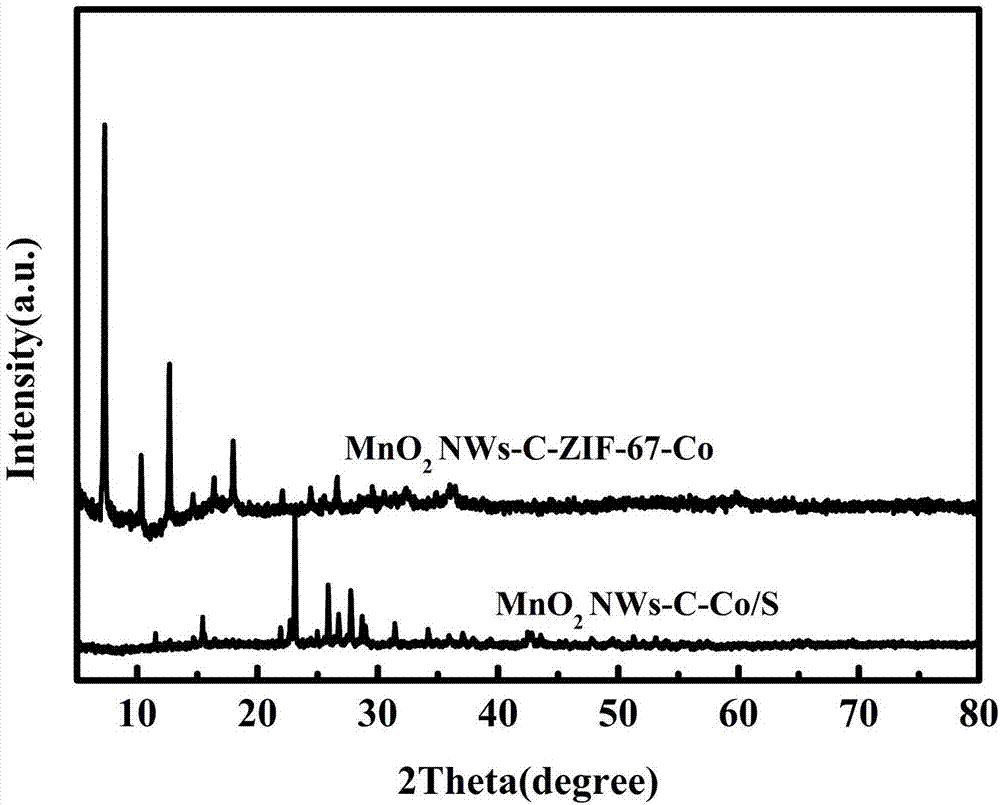

[0031] In the second step, the prepared ZIF-67-MnO 2 NWs were put into a tube furnace for carbonization, held at 300 °C for 3 h in an argon atmosphere, and the heating rate was 1 °C / min. Take it out of the tube furnace when it drops to room temperature, and you can get to the MnO ...

Embodiment 2

[0033] In step 1, first dissolve 0.04g of manganese oxide nanowires in 20mL of methanol solvent, and disperse evenly by ultrasonic; at the same time, take 0.2g of 2-methylimidazole and dissolve them in 10mL of solvent, and disperse evenly; Add 0.15g SDS, ultrasonically disperse evenly; then, add 0.2g zinc nitrate hexahydrate to the solution added with SDS, ultrasonically disperse evenly; finally, mix the methanol solution of 2-methylimidazole with the solution containing zinc nitrate hexahydrate, seal Let the reaction stand for at least 20 hours, wash the reaction product with methanol three times, and dry at 60°C to obtain ZIF-8-MnO 2 NWs are materials with a unique serial structure.

[0034] In the second step, the prepared ZIF-8-MnO 2 NWs were put into a tube furnace for carbonization, held at 600 °C for 3 h in an argon atmosphere, and the heating rate was 1 °C / min. Take it out of the tube furnace when it drops to room temperature, and you can get the material MnO NWs-C-C...

Embodiment 3

[0036]Step 1, firstly dissolve 0.05g zinc oxide nanowires in 50mL N,N-dimethylformamide solvent and disperse uniformly by ultrasonic; then add 0.2g PVA into the solution and disperse uniformly by ultrasonic; then 0.3g hexahydrate Add cobalt nitrate and 0.3g benzimidazole into the solution and ultrasonically disperse evenly; finally, transfer the evenly dispersed solution into a 100mL reactor for hydrothermal reaction at 120°C for three hours, wash the obtained product with ethanol three times, and dry at 60°C Then ZIF-7-ZnO NWs, a material with a unique serial structure, can be obtained.

[0037] In the second step, the prepared ZIF-7-ZnO NWs were put into a tube furnace for carbonization, and kept at 500°C for 3h under an argon atmosphere, with a heating rate of 1°C / min. Take it out of the tube furnace when it drops to room temperature, and you can get the material ZnO NWs-C-Co, then mix the material with S at a weight ratio of 1:3, use a reactor to fix sulfur, and keep it wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com