Anionic polymer grafted chitosan magnetic composite microsphere and preparation method and application

An anionic polymer, magnetic composite microsphere technology, applied in separation methods, alkali metal compounds, chemical instruments and methods, etc., can solve the problems of unsatisfactory adsorption effect, secondary pollution separation and recycling, etc., to achieve regeneration and reuse Easy, low recovery cost, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A preparation method of anionic polymer grafted chitosan magnetic composite microspheres, comprising the steps of:

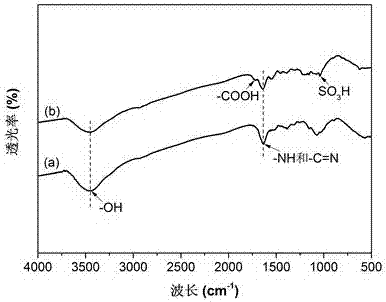

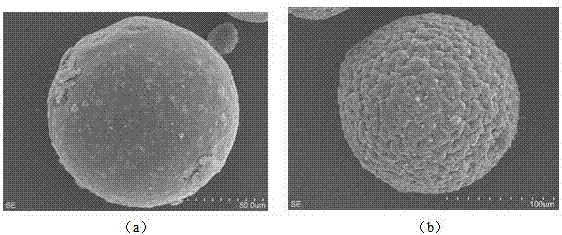

[0034] 1. Cross-linking reaction: Dissolve 2.5g chitosan in 85.0ml hydrochloric acid solution (hydrochloric acid mass fraction 0.5%), prepare a solution with chitosan mass fraction 3%, Fe 3 o 4 Nanoparticles were ultrasonically dispersed in the above solution (Fe 3 o 4 The mass ratio of nanoparticles to chitosan is 1:5), after stirring evenly, add to 250ml cyclohexane (the volume ratio of cyclohexane to chitosan solution is 3:1), after mixing evenly, add 3ml mass fraction 50% glutaraldehyde aqueous solution (the molar ratio of glutaraldehyde to chitosan is 1:1), cross-linked at 50°C for 1 hour to obtain chitosan magnetic composite microspheres, which were scanned by infrared spectroscopy, as shown in figure 1 As shown in the middle curve a, the composite microsphere has the characteristic absorption peaks of hydroxyl group, imino group and C=N double b...

Embodiment 2

[0039] 1. Cross-linking reaction: (same as Example 1).

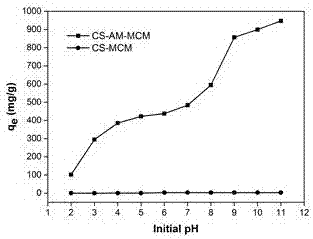

[0040] 2. Copolymerization reaction: fill the obtained chitosan magnetic composite microsphere dispersion with N 2 After 10 minutes, add potassium persulfate (potassium persulfate is 10% of the amount of chitosan), and after 5 minutes, add anionic monomer 2-acrylamide-2-methylpropanesulfonic acid (AMPS) (AMPS and chitosan The ratio of sugar to substance is 5:1), and the copolymerization reaction was carried out at 50°C for 3 hours. After the completion of the copolymerization reaction, anionic polymer-grafted chitosan composite microspheres were obtained, and its adsorption capacity for methylene blue was 451.33 mg / g.

Embodiment 3

[0042] 1. Cross-linking reaction: (same as Example 1).

[0043] 2. Copolymerization reaction: fill the obtained chitosan magnetic composite microsphere dispersion with N 2 After 10 minutes, add potassium persulfate (potassium persulfate is 10% of the amount of chitosan substance), and after 5 minutes, add anionic monomer acrylic acid (AA) (the ratio of AA to chitosan substance is 5:1) , Copolymerization reaction at 50℃ for 3h, after the completion of the copolymerization reaction, anionic polymer grafted chitosan composite microspheres were obtained, and its adsorption capacity for methylene blue was 302.86 mg / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com